Change Management

What are F-tags and why digitize them?

What are F-tags and why digitize them? Andy Pritchard | March 17, 2022 | 4 min read F-tag is a visual work order system where staff apply paper tags to machines when a process abnormality is observed. “F” stands for Fuguai, which is Japanese word that means “deviation” or “abnormality”. F-tags can be for…

Read MoreWhy are paper forms insufficient for inspection schedules?

Digitizing an inspection schedule takes some effort, so you want to get it right the first time. As you have probably discovered if you’re managing an inspection schedule, paper forms are not ideal for ensuring inspections are completed correctly and on time.

Read MoreHow to simplify inspection schedules

Your front line staff are busy and your inspections are important. Simplification goes a long way to ensuring inspections get done on-time and correctly.

Read MoreWhat are the 7 steps of autonomous maintenance?

Quick overview of the 7 steps of Autonomous Maintenance from Increasing Operator Knowledge to Establishing Continuous Improvement and everything in between.

Read MoreBest Practices for GMP Audit Checklist

Home / Zero Blog / Best Practices for GMP Audit Checklist Best Practices for GMP Audit Checklist Andy Pritchard | December 5, 2021 | 4 min read TABLE of contents What does a standard Operational Audit Schedule for a typical food company look like? If harnessed correctly, GMP audits can have a massive…

Read MoreBest Practices to ensure success with Behaviour Based Safety Observations

Webinar Behavior Based Safety Observations Learn about Best Practices and Common Pitfalls for BBSO Behavior Based Safety Observations help organizations keep safety “top-of-mind” by continuously reinforcing and training on safety protocols and best practices. Organizations are reaping the benefits with cost savings and a safer working environment. We have identified some core challenges that our…

Read MoreTop 5 Benefits of Paperless Factory Operations

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. Schedule a Free Demo Today! This article reviews the following topics: Real-Time Visibility Cost Savings Employee Engagement Simplicity & Structure Compliance If you are reading this you have probably hit a…

Read More5 Tips to Ensure Effective Change Management in Manufacturing.

Topics covered in this article: Standardization is key. Consult all stakeholders especially those affected most by the change. Take your time. Ensure your process is compliant with regulatory requirements. Provide a variety of ways for staff to understand the change before you implement it. Heraclitus had it right when he coined the saying “Change is…

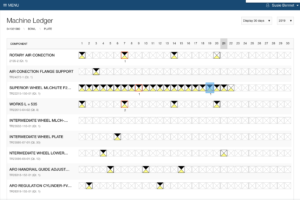

Read MoreUnderstanding the Machine Ledger

The Machine Ledger is used in World Class Manufacturing to better understand machines, sections, assemblies, and components so that maintenance teams can more effectively predict failures and plan preventive maintenance activities.

Read More4 ways to reduce waste from your Continuous Improvement process

Kaizen is the process of incrementally improving processes by eliminating “waste”. Small improvements over time can have a huge impact on productivity and the bottom line. Waste can come in many forms, including unnecessary inventory, physical movements and scrap. Kaizen only works if everyone is involved, which includes top management and, more importantly, the workers…

Read More