Operational Excellence

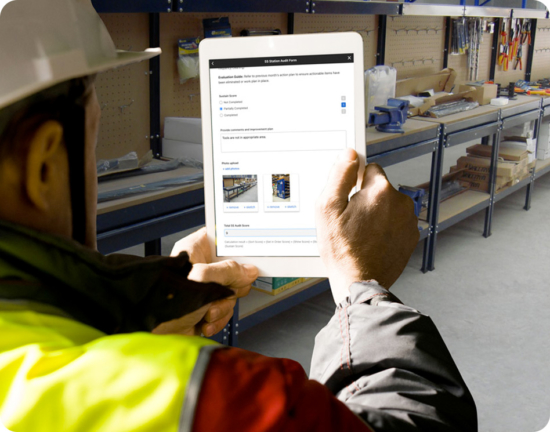

How to gather data to support your 5S business case

To substantiate the case for 5S adoption, gathering benchmark data and evidence-backed KPIs becomes crucial. The right KPIs not only provide quantifiable data but also serve as compelling evidence to support the business case for 5S implementation.

Read MorePain Points Solved with 5S

When planning your 5S implementation, it is important to align the program’s objectives and benefits with the strategic priorities of your organization.

Read MoreTop 5S benefits for manufacturing companies

The 5S methodology can have a significant positive impact on many success factors for your business, including efficiency gains, enhanced safety and quality, improvements to employee engagement and moral, cost savings and continuous improvement.

Read MoreIs 5S right for you?

If you are uncertain whether 5S is right for your facility askyourself and your team the following questions.If the answer was “yes” to one or more of these questionsyou may find 5S to be very beneficial to your organization.

Read MoreTop 5 Frontline Employee Engagement Best Practice

Are you tired of slogging through your workday, feeling unfulfilled and disconnected from your organization? Do you wish you could be part of a culture of excellence that inspires innovation, collaboration, and engagement?

Well, look no further! We have compiled some of the best practices we’ve seen in our 10 years of working with organizations around the world to help you build a culture of engagement and achieve amazing results.

Read MoreHow to increase Employee Engagement by focusing on Ease and Usefulness

According to numerous studies Continuous Improvement program participation can be predicted by the amount of intention employees have to participate, which is inflences by Ease and Usefulness of participation.

Read MoreWhat is Daily Management System (DMS)and how does it help manufacturers?

The Daily Management System (DMS), also known as Daily Direction Setting (DDS), is a framework for managing operational performance in manufacturing organizations. It is a structured approach to managing day-to-day operations that focuses on continuous improvement and waste reduction.

Read MoreHow skill development increases frontline employee engagement in manufacturing organizations

Investing in employee skills and training can have numerous benefits for manufacturing organizations, including increased employee engagement, motivation, retention, productivity, and quality.

Read MoreHow elevated safety increases employee engagement at manufacturing organizations

Elevated safety can have a positive impact on employee engagement at manufacturing organizations by building trust, boosting morale, reducing stress, increasing productivity, and improving retention.

Read MoreHow does workflow automation increase collaboration in a manufacturing facility?

Workflow automation can increase collaboration in a manufacturing facility in several ways. By automating the flow of information between different systems and teams, manufacturers can improve communication and collaboration, leading to better decision-making and more efficient operations.

Read More