Operational Excellence

GMP Operational Audit Schedule for a Food Company

GMP Operational Audit Schedule for a Food Company Andy Pritchard | Dec 7, 2021 | 5 min read What does a standard Operational Audit Schedule for a typical food company look like? Organizations involved in the manufacturing and distribution of food are required by law to audit their processes and equipment to ensure basic…

Read MoreBest Practices to ensure success with Behaviour Based Safety Observations

Webinar Behavior Based Safety Observations Learn about Best Practices and Common Pitfalls for BBSO Behavior Based Safety Observations help organizations keep safety “top-of-mind” by continuously reinforcing and training on safety protocols and best practices. Organizations are reaping the benefits with cost savings and a safer working environment. We have identified some core challenges that our…

Read More5S Best Practices

The 5S methodology is a simple practice that helps your organization realize efficiency gains quickly by optimizing the cleanliness, order and organization of each workstation. There are some common pitfalls that organizations can encounter when implementing a 5S program. Here are some 5S best practices that will ensure a better chance at success.

Read More5S Simple Implementation Plan

Everything you need to know about 5S including a simple implementation plan and how to sustain with a 5S auditing program.

Read MoreTop 5 Benefits of Paperless Factory Operations

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. Schedule a Free Demo Today! This article reviews the following topics: Real-Time Visibility Cost Savings Employee Engagement Simplicity & Structure Compliance If you are reading this you have probably hit a…

Read MoreWhy digitize factory operations?

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: Cost Savings Real-time Visibility Automation Simplicity & Structure Compliance There are countless benefits to transitioning paper and spreadsheet-based processes to a digital framework. Paper has…

Read MoreThe Problem with Paper

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: Stagnant Waste Time Errors Inconsistent Why do paper forms limit factory operations and continuous improvement? Manufacturers come in a lot of different shapes and sizes.…

Read MoreThe Principles of Operational Excellence in Manufacturing

This article includes: Why improve? How is Operational Excellence Different? How does Operational Excellence Work? Principle 1: Understand Customer Value and Standard Operating Procedures (SOP) Principle 2: Deploy a system that recognizes defects, corrects them quickly, and prevents them from recurring in the future. Principle 3: Foster a culture that continuously pursues perfection. Principle 4:…

Read MoreEnabling the Cycle of Operational Excellence in Manufacturing

Operational Excellence is a process and a result. Operational Excellence (OpEx) is a management framework for organizations to focus on growth and streamline productivity. It involves creating standard operating procedures (SOPs) that are clear and followed consistently by staff. These SOPS are easy to execute and staff feel enabled to complete them efficiently. The net…

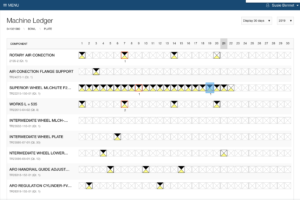

Read MoreUnderstanding the Machine Ledger

The Machine Ledger is used in World Class Manufacturing to better understand machines, sections, assemblies, and components so that maintenance teams can more effectively predict failures and plan preventive maintenance activities.

Read More