Continuous Improvement Programs

Sorry, we couldn't find any posts. Please try a different search.

"It's easy to anticipate safety issues with Weever."

“In a warehouse setting it's very easy to fall into the trap of being reactive. With Weever we are 60-70% proactive. That's huge!"

Kody Crossen | Operations Manager of EHS, Walmart DC6080

C.I.

We work with organizations of all shapes and sizes who are frustrated with paper forms and spreadsheets and want to get more out of their C.I. Management System. They want to save money, become more efficient, and spend their time more wisely.

100K+

Global Users

MILLIONS

of jobs completed

11

Languages

"The Weever suite is easy to understand and the support from the team has been amazing!"

Laura Curtis - Operational System and Process Manager, HelloFresh

"Weever saves me time, makes data visible and drives results!"

DENAIR M. - Training Manager

"Weever has changed how I run our business."

Ingrid K. - Plant Director

"Weever is extremely easy to use and simple to manage."

NICKI V - CI Engineer

"Weever gives me immediate insights into my business."

COLIN H. - Operational Excellence Manager

"The Weever team are extremely helpful and are always on hand to help with any questions or queries we may have."

Mel Cadle - Op Ex Lead Process Engineer, HelloFresh

Making Better Continuous Improvement Data Available Via Digital Transformation

Juan Vizcaya is a process engineer with a decade of experience helping CPG manufacturers implement continuous improvement processes. Juan’s goal was to support the implementation of a lean manufacturing system. To do that he needed data on production, productivity, and other general metrics and inputs required for OEE calculations.

SCHEDULE A DEMO

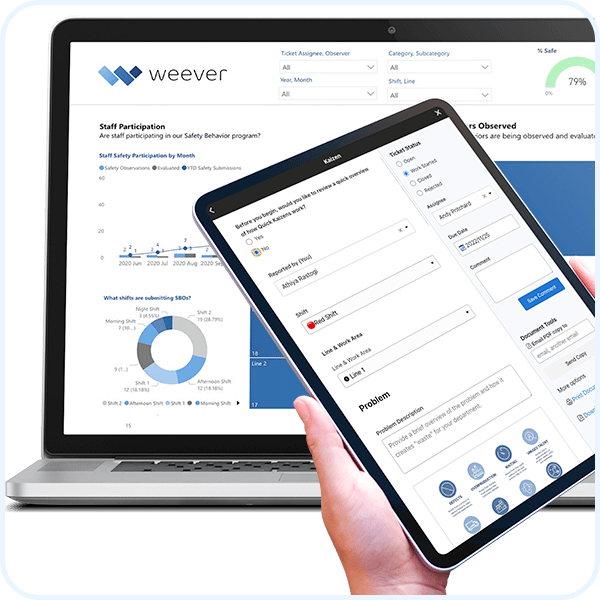

Take a Guided Tour.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.