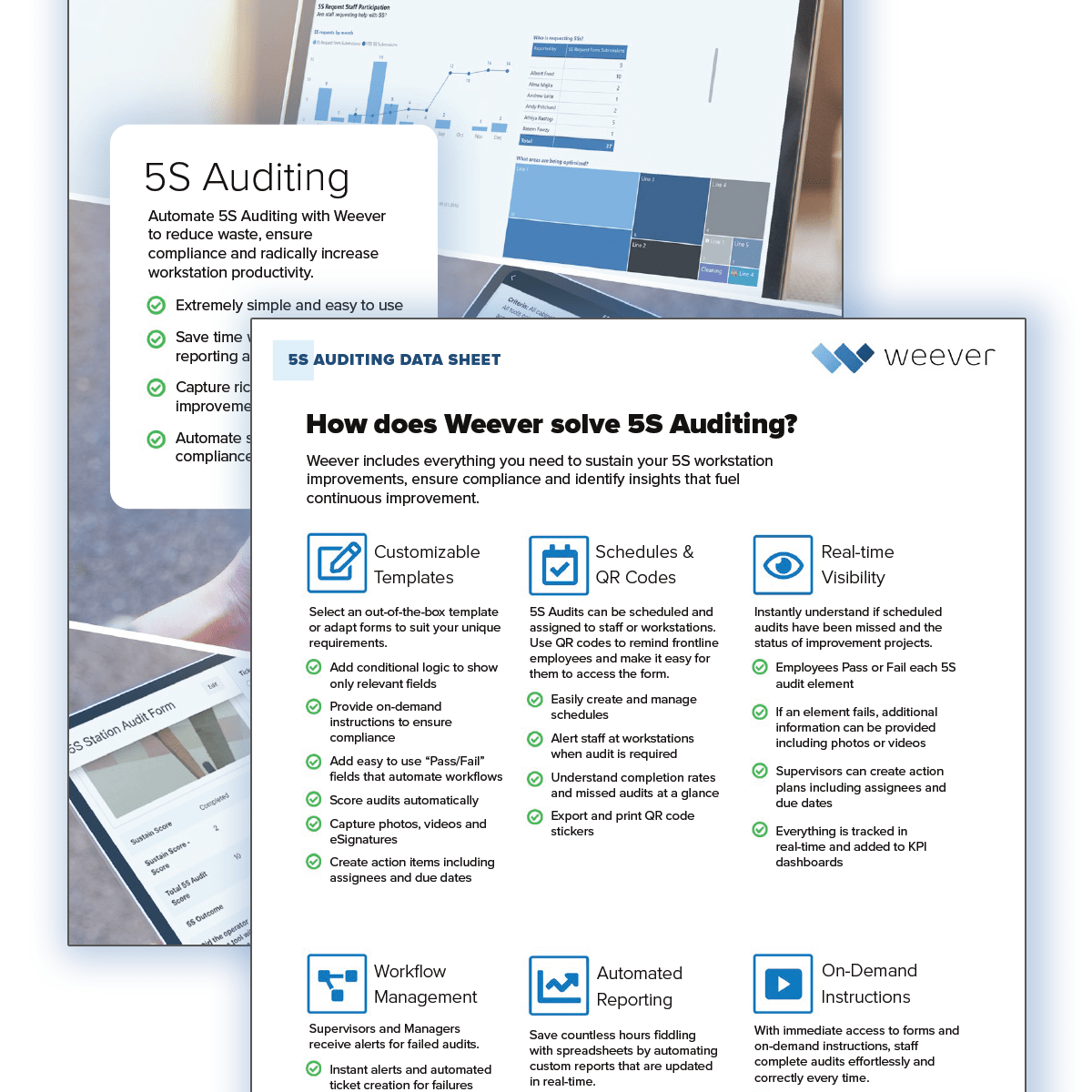

5S Auditing

We are global leaders in 5S Auditing because we provide everything you need to get the job done.

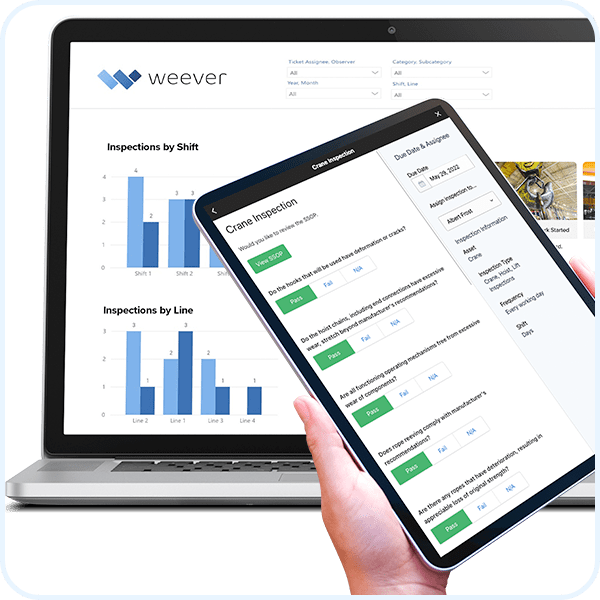

Customizable Templates

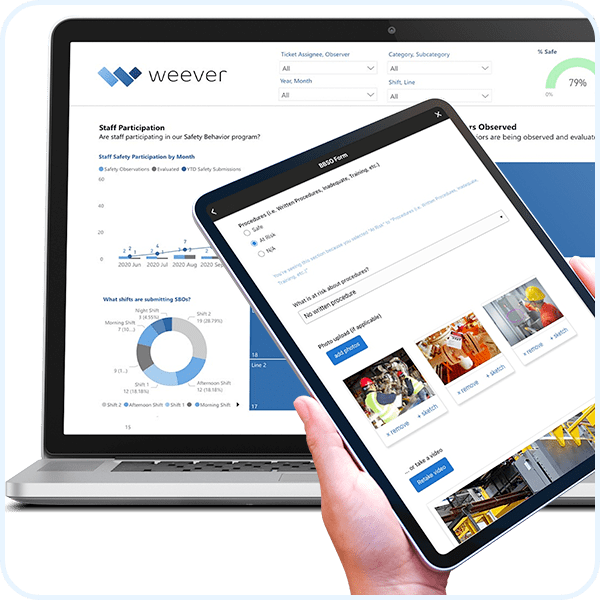

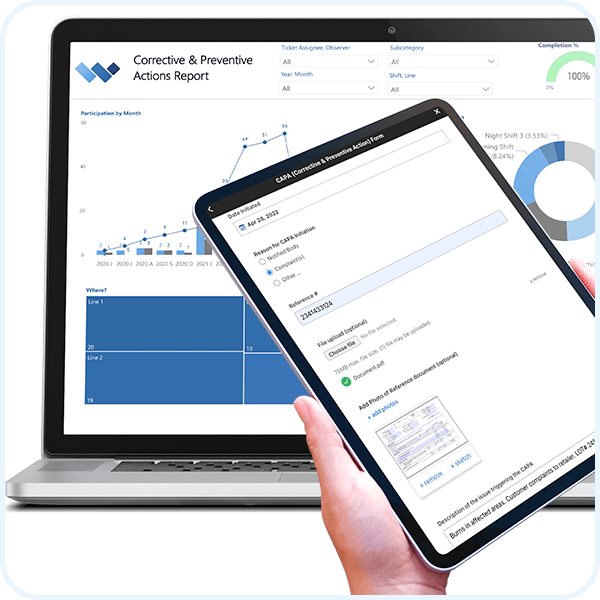

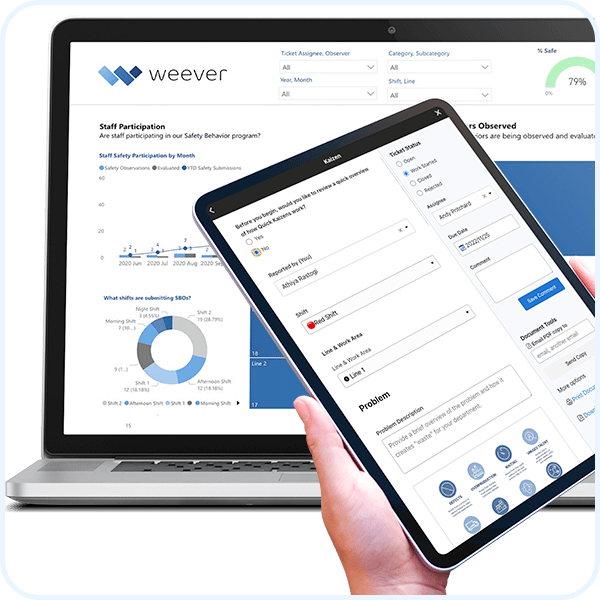

Dashboard Reporting

Automated Workflows

Schedule Management

Real-time Visibility

On-Demand Instructions

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware

SOlve 5S with Weever

Say goodbye to inefficient 5S audits and hello to Weever.

Are you struggling with paper forms and spreadsheets for your 5S Auditing program? Get in touch to see how Weever can help you solve your 5S audits today!

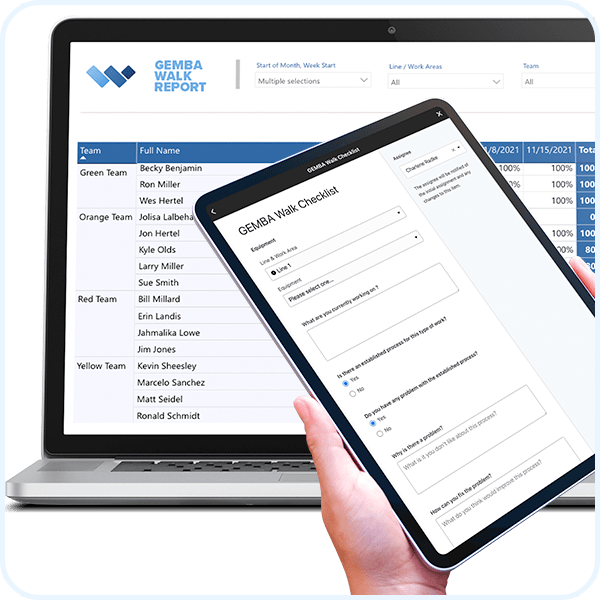

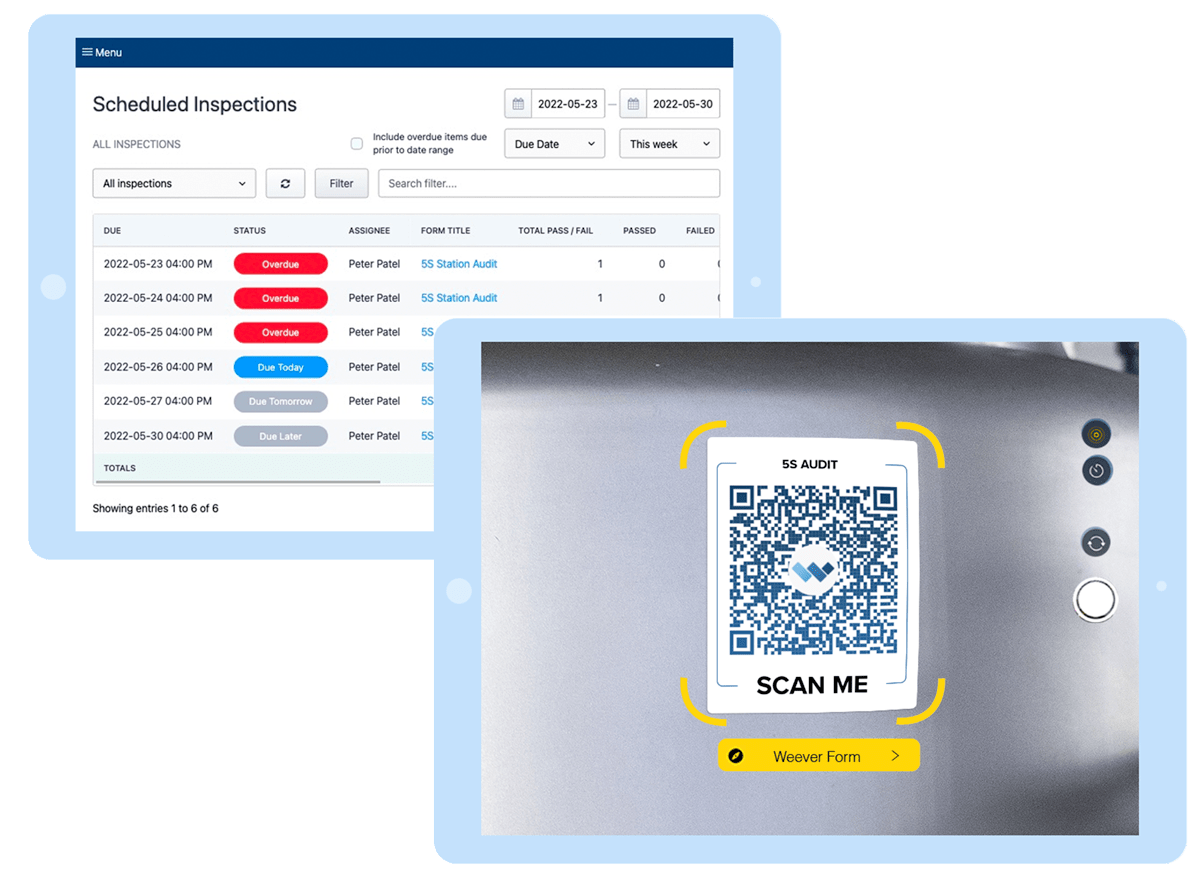

Schedules & QR Codes

Ensure quick adoption and compliance.

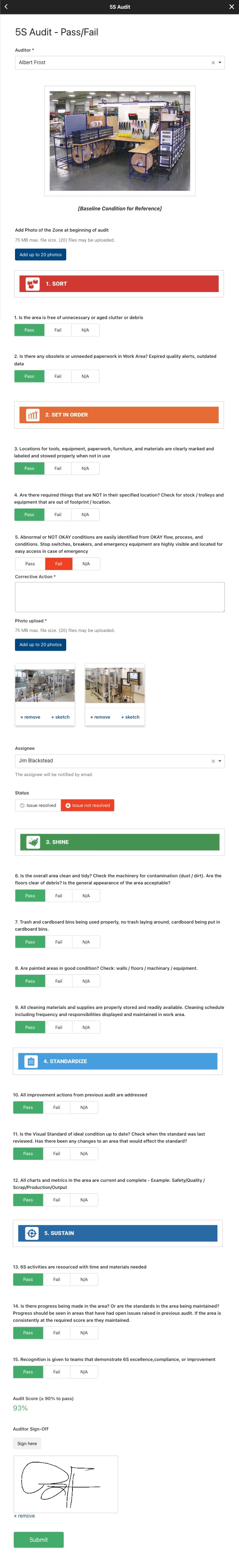

Digital DATA CAPTURE

Get it done correctly every time.

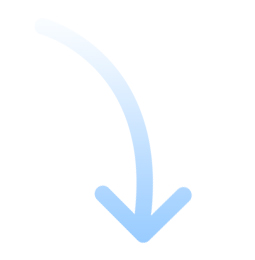

WORKFLOW AUTOMATION

Evaluate. Improve. Sustain.

REAL-TIME REPORTING

Automate Business Intelligence.

Download 5S Data Sheet

The 5S methodology is a great way to radically enhance productivity, reduce waste and build a culture of excellence.

However, without an effective 5S Auditing program, the work to optimize workstations will be wasted as frontline staff fall back into old routines.

The Weever Platform ensures audits occur based on a schedule. The platform also makes it easy for staff to conduct audits, escalate issues, and automate KPI reports.

Download our 5S Auditing Software Data Sheet to understand how Weever solves 5S auditing.

Cycle time stopwatch

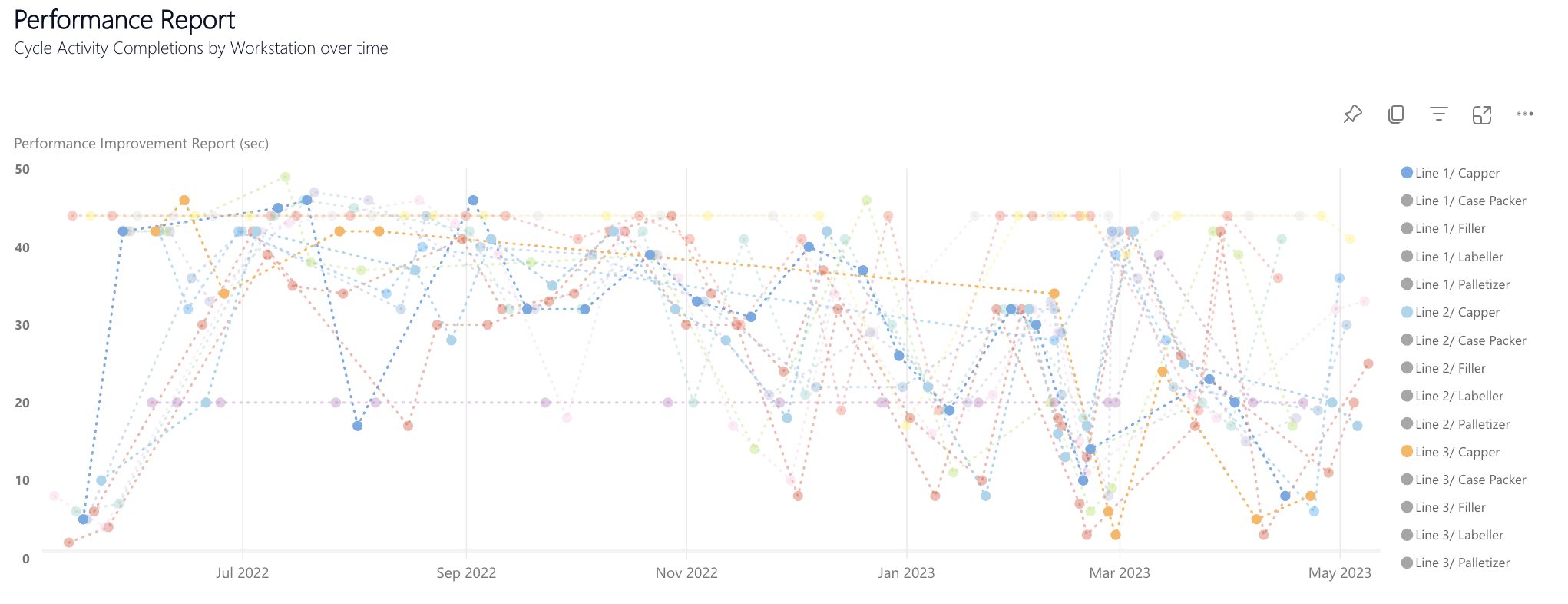

Measure Real Impact

Are you challenged to prove the ROI for your 5S program?

Use cycle times to show productivity increases by work area over time. Prove program effectiveness and better understand what areas would benefit most from your focus.

“Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report.”

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

“It’s shifted our safety culture because now we are much more focused on what we should be looking at.”

Kody Crossen, Operations Manager of EHS

Do it all with Weever.

Weever is a comprehensive workflow management platform that is used to automate safety, quality, maintenance, production, compliance, continuous improvement and training operational requirements.