USA Food Manufacturing Compliance Requirements

Compliance for manufacturing organizations is comprised of technical, legal and corporate requirements, regulations and practices manufacturers must comply with in order to produce and market products.

Numerous areas of compliance can come to bear on manufacturers directly or indirectly, including:

- Product safety

- Health, safety, and environmental impact

- Data protection

- Export controls

- Anti-corruption

- IT safety and security

- Fair competition

- Employment law

The strategic goal of most manufacturers is to produce competitive products, operate profitably, and grow their business in an environment of increasing globalization and elevated product development costs. This can be challenging enough in itself without adding the 3rd Dimension of Compliance, which is less concerned with what is produced and more concerned with how it is produced.

Risks of Non-Compliance

The risk of non-compliance has become an increasingly major concern in recent years, particularly for manufacturers with operations in multiple countries and jurisdictions. Simply put, if you’re not compliant you can’t play. This development has been further heightened by the increasing role of governmental regulatory bodies in certain industry sectors, along with the emergence of global standards to address the increasingly global nature of manufacturing. Regulatory compliance has become a major milestone not only in product development but also in guiding how manufacturers go to market.

If management fails to create an environment that ensures manufacturing compliance—or lacks documentation to prove all necessary steps have been taken to achieve it—it can be held accountable for compliance breaches. With this in mind, compliance must be an ingrained part of day-to-day business operations, and therefore part of the organizational culture. Employee involvement in and acceptance of compliance tasks, including a complete understanding of requirements and objectives, are integral aspects of a sound compliance practice for manufacturing.

Compliance Requirements for Food Companies include:

1. FDA Regulations

CFR (Code of Federal Regulations) 21 Part 11 and Part 820

The core mandate guiding FDA regulatory oversight is consumer safety. In response to this, the FDA has defined Good Manufacturing Practices (GMP) that dictate the necessary measures that must be taken to ensure that quality systems and processes are in place to consistently produce safe, quality products. Therefore, manufacturers in these sectors seek a manufacturing certificate of compliance indicating that they meet GMP. According to David Nettleton at computersystemvalidation.com, manufacturing Execution Systems (MES), including Electronic Batch Record (EBR) management systems, must be compliant with 21 CFR Part 11 and Part 820. These controls include audits, system validations, audit trails, electronic signatures, and documentation for software and systems involved in processing electronic data that are (a) required to be maintained by the FDA predicate rules or (b) used to demonstrate compliance to a predicate rule.

2. HACCP

Hazard Analysis Critical Control Points

HACCP is a management system in which risk-based preventive controls are conducted to avoid the contamination of biological, chemical, and physical hazards in the final food product. HACCP when applied correctly as a control process, will aid the prevention, elimination or reduction of critical levels of known and expected food contaminants. HACCP regulations include the Safe Food for Canadians Act (SFCA) and the FDA Food Safety Modernization Act (FSMA). HACCP certification is a global defining requirement for effective control of biological, chemical and physical food hazards. Compliance to HACCP, will transform brands, enable an effective entry-to-market means, and bring about new business opportunities. Inspection and validation by third-party certification bodies reaffirms an organization’s commitment to food safety.

3. OSHA

Occupational Safety & Health Administration

OSHA is responsible for protecting worker health and safety in the United States. OSHA coverage extends to most private sector employers and their workers. OSHA determines which standards and requirements apply to which workplace environments and then enforces employer adherence to those standards and requirements. To comply with OSHA requirements, employers must take a number of specific actions; those include inspecting the workplace for potential hazards, eliminating or minimizing hazards, keeping records of workplace injuries and illness, training employees to recognize safety and health hazards, and educating employees on precautions to prevent accidents.

4. EPA

Environmental Protection Agency

The EPA seeks to protect and conserve the natural environment and improve the health of humans by researching the effects of and mandating limits on the use of pollutants. The EPA is charged with determining safe tolerance levels for chemicals and other pollutants in food, animal feed, and water. The EPA oversees a number of programs intended to promote energy efficiency, environmental stewardship, sustainable growth, air and water quality, and pollution prevention. The EPA enforces its findings through fines, sanctions, and other procedures.

5. International Standards

With the advent of globalization, international standards have become increasingly important to manufacturers looking to be compliant across international markets. With the implementation of the EMC Directive and similar regulations in other countries, regulatory compliance has become a major milestone in product development and marketing for most manufacturers. New and harmonized standards for manufacturing compliance continue to be developed.Key international industry standards for manufacturing compliance include:

- ISO 9001

- ISO 13845

- IEC 61215

- IEC 61646

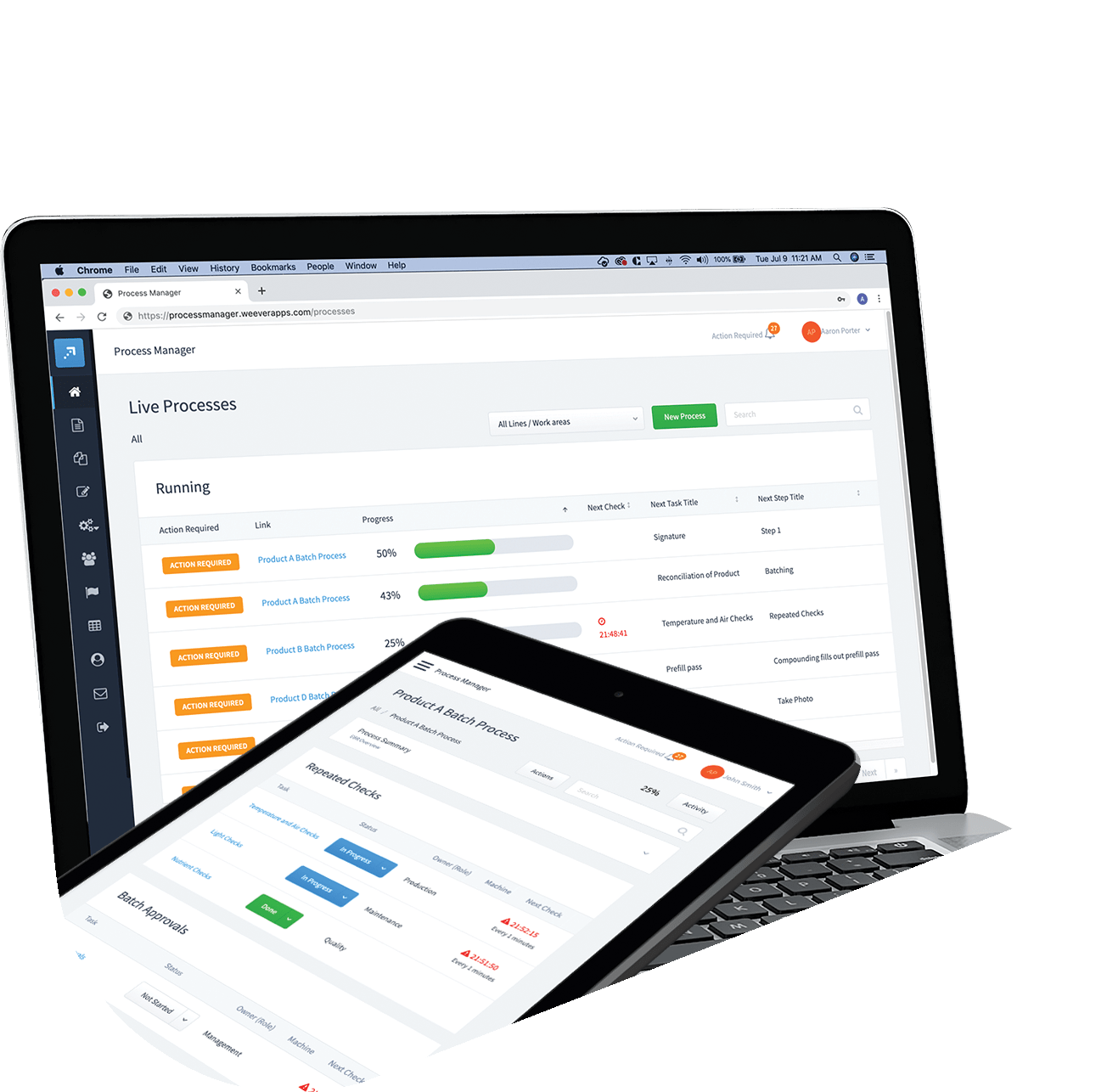

Weever Process is an effective workflow automation tool to collect data and automate compliance regulations workflows. Process Manager includes features that can be configured to your specific business practices while ensuring the high levels of traceability and data integrity required by governing agencies.

SCHEDULE A DEMO

Take a Guided Tour.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware