4 ways to reduce waste from your Continuous Improvement process

Kaizen is the process of incrementally improving processes by eliminating “waste”. Small improvements over time can have a huge impact on productivity and the bottom line.

Waste can come in many forms, including unnecessary inventory, physical movements and scrap. Kaizen only works if everyone is involved, which includes top management and, more importantly, the workers who do the job every day. What fuels the kaizen process is engaged workers who are thinking about smart ways to be more efficient. No suggestions = no improvements.

Ironically, some businesses can find the kaizen process to be a distraction (e.g. “waste”) from their core business. Getting staff to complete suggestions, supervisors to evaluate and assign action plans, workers to execute - it feels like a lot of work for a small improvement in efficiency. This is what has motivated our customers to look for ways to remove waste from their kaizen event process.

Here are some tips that you can deploy now to more out of your continuous improvement (CI) process.

1. Make the suggestion process as simple as possible.

When first initiating a CI plan, staff may grumble about the additional work required to submit suggestions. Don’t worry - this will soften when they begin to results. Also, a highly intuitive, simple, and powerful way to submit suggestions will get the most information in the least amount of time and ease worker frustrations.

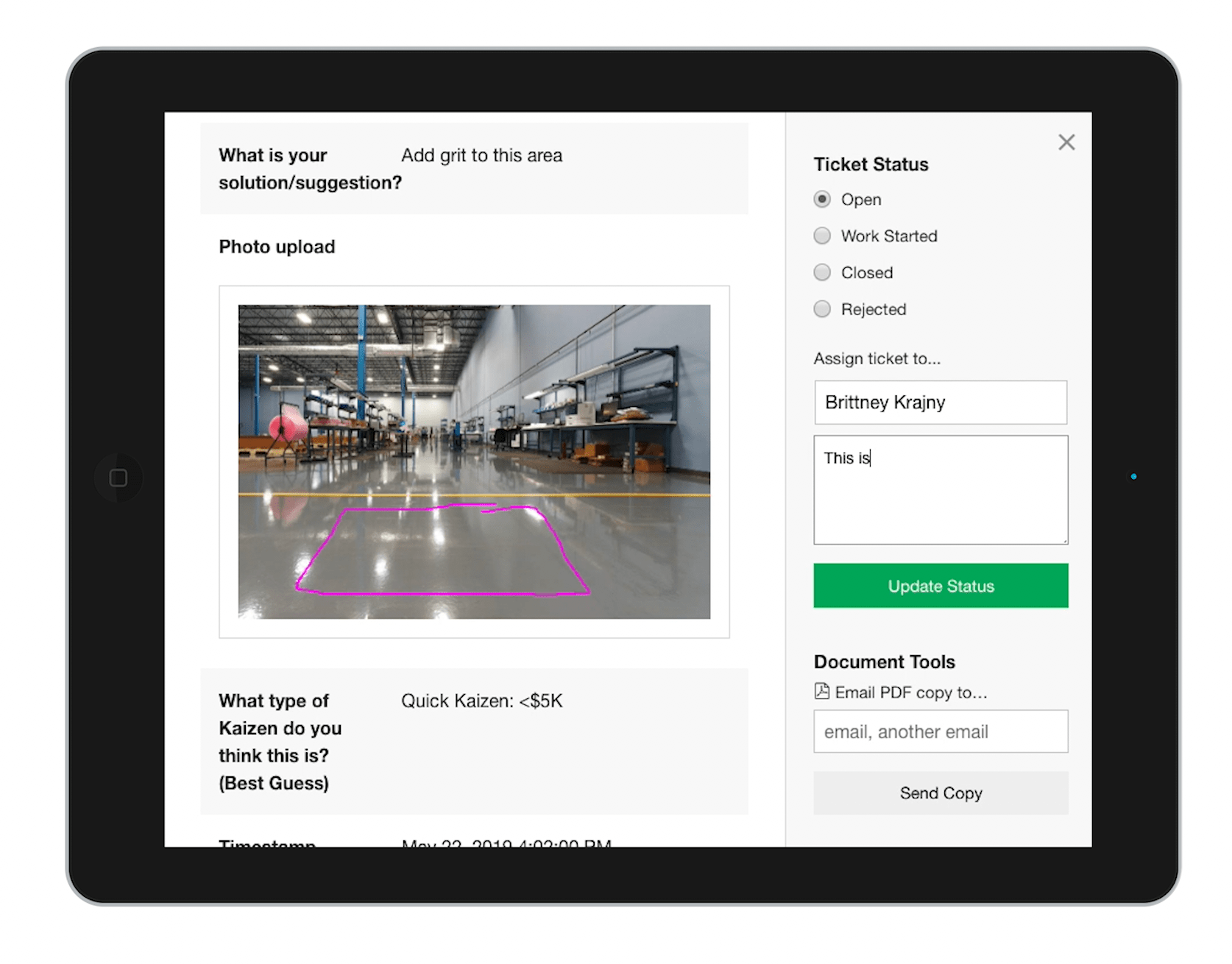

Cloud-based web-apps work best because they can be quickly opened on any device, including the worker’s own phone. Photo capture with “sketch” annotation is an excellent feature, because photos can “say a thousand words”. Use a form builder tool to tailor your suggestion form(s) to your specific requirements.

2) Engage staff in the solution

When a poor suggestion is made, resist the knee jerk reaction of rejecting it immediately. Rejected suggestions are a quick way to further disengage workers and, by asking questions, staff will see that management is serious about CI.

There also may be a hidden insight behind the scenes. Engage the suggester by requesting additional information or simply asking a number of “why” questions to get to the root of the problem they are solving, then work out from there.

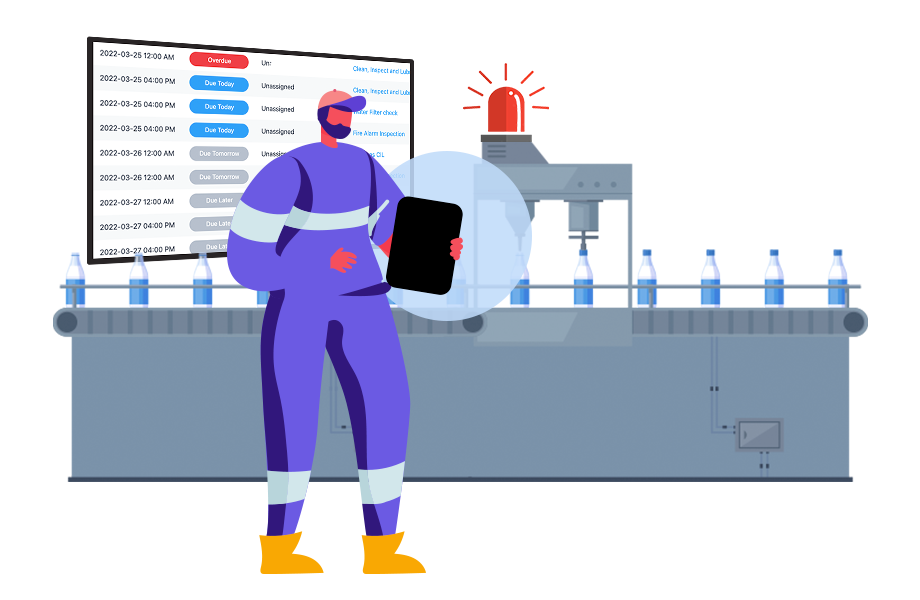

3) Make the process public to increase accountability

If you are having an issue moving the workflow along, providing all staff with access to real-time project status is a good way to increase accountability.

Public forums keep people accountable. You may find that this is a more productive way to keep the process moving forward than harassing your staff.

4) Celebrate Wins

When the process works and an action plan is completed, celebrate it by showing off the improvement and how it was realized. This will help staff see that their suggestions can truly make an impact on their own work as well as others. Create a KPI to measure the impact and circle back in a month or so to present the bottom-line impact that started with a great suggestion.

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware

Learn about the Platform.

Download the brochure to get all the details about how Weever works.