Operational Excellence

The Pursuit of Perfection: Why the 4 Principles of Operational Excellence in Manufacturing Matter

The Pursuit of Perfection: Why the 4 Principles of Operational Excellence in Manufacturing Matter July 31, 2025 In today’s challenging manufacturing environment, staying competitive isn’t optional, it’s existential. Manufacturers are under constant pressure to improve efficiency, reduce costs, and innovate without compromising quality. And that’s where operational excellence (OpEx) comes in. It’s not just a…

From Monitoring to Impact: Operational Excellence in Manufacturing

From Monitoring to Impact: Operational Excellence in Manufacturing June 2025 Operational Excellence is more than a goal. It’s a continuous improvement journey. Striving for Operational Excellence isn’t just about refining processes, it’s a strategic priority that delivers measurable results. According to McKinsey, manufacturers that effectively implement OpEx initiatives can increase productivity by 25-30% and reduce…

Why invest in Human Intelligence (HI)

Why invest in Human Intelligence (HI) Striking a balance between Artificial and Human Intelligence Industry 4.0 and Artificial Intelligence offer vast opportunities for organizations to improve efficiency and bottom line company performance. However, in the past 15 years, productivity gains in manufacturing have stagnated. Since 2007, annual growth has decreased to .7%. Companies are spending…

Making the unpredictable predictable

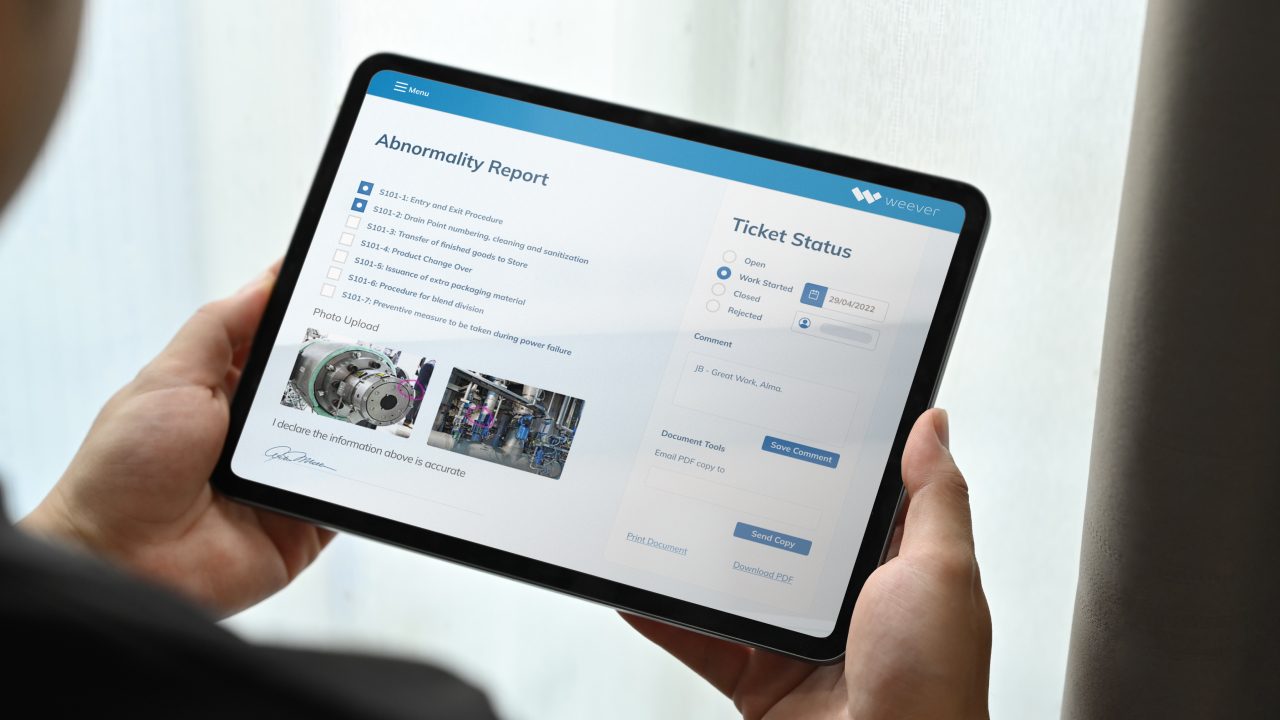

Making the Unpredictable Predictable The Foundation of Continuous Improvement As an experienced manager, you are skilled at managing the day-to-day processes within your organization. You know all the Standard Operating Procedures that dictate how to deal with events as they arise. And you rely on systems that are perfectly tuned to manage predictable events that…

The Benefits of Digitizing your Factory Operations

Benefits of Digitizing Factory Operations 5 primary benefits that are realized by eradicating paper forms and spreadsheets from your operations. Digitization is the process of eliminating paper from your operations and there are countless benefits to transitioning paper and spreadsheet-based processes to a digital framework. Paper has been used for centuries to collect data and…

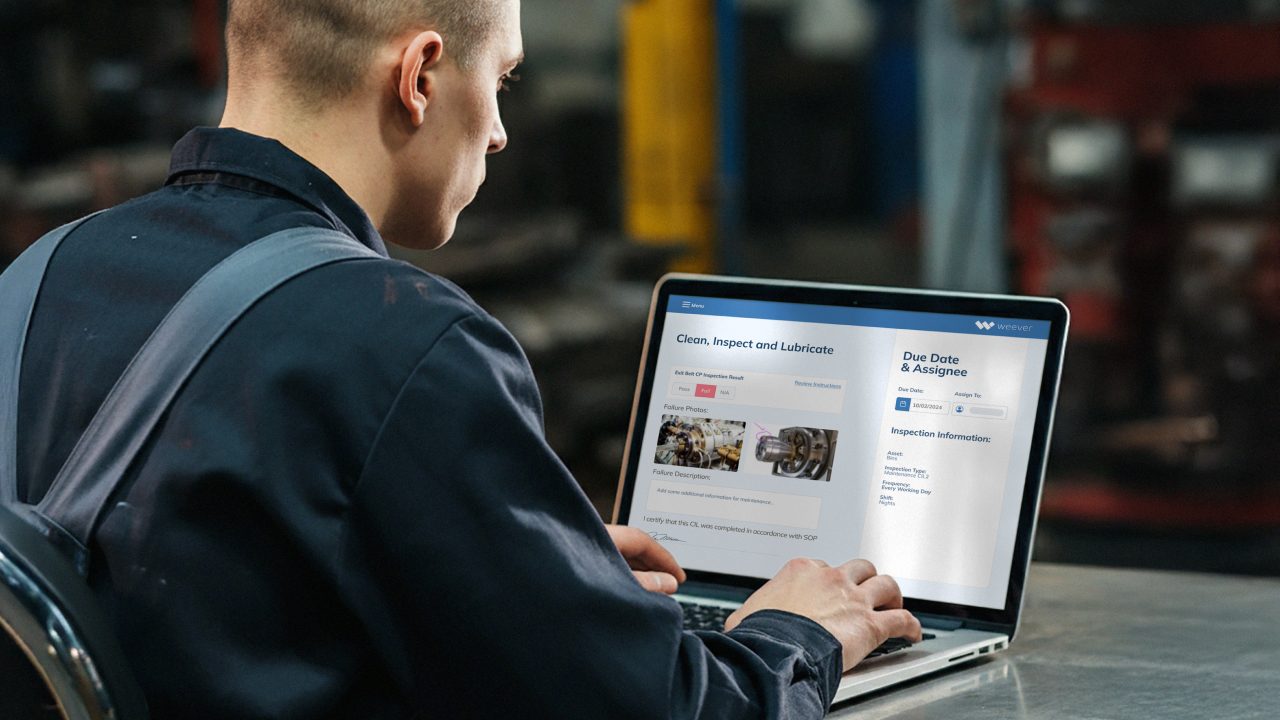

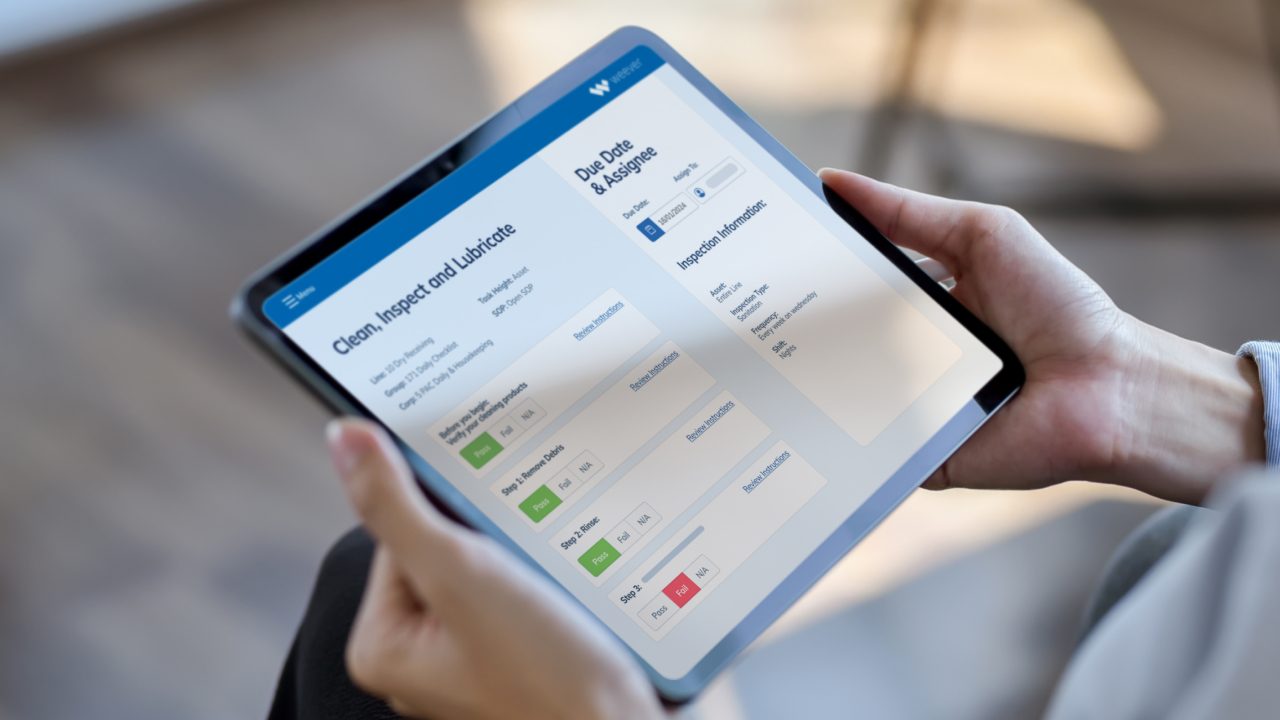

How Does Clean Inspect Lubricate (CIL) Work: A Step-by-Step Guide with Weever

How Does Clean Inspect Lubricate (CIL) Work: A Step-by-Step Guide with Weever Learn how Weever enhances the Clean Inspect Lubricate (CIL) process for optimal equipment efficiency and reliability. Streamline tasks, gain insights, and boost performance. Why Clean Inspect Lubricate (CIL) is Essential The Clean Inspect Lubricate (CIL) process maintains equipment efficiency and effectiveness in any…

How Can We Establish Effective Standards and Protocols for Lubrication and Inspection with Weever?

Boost efficiency and productivity in manufacturing operations with Weever Software’s configurable program templates. Learn how to streamline workflows and enhance performance.

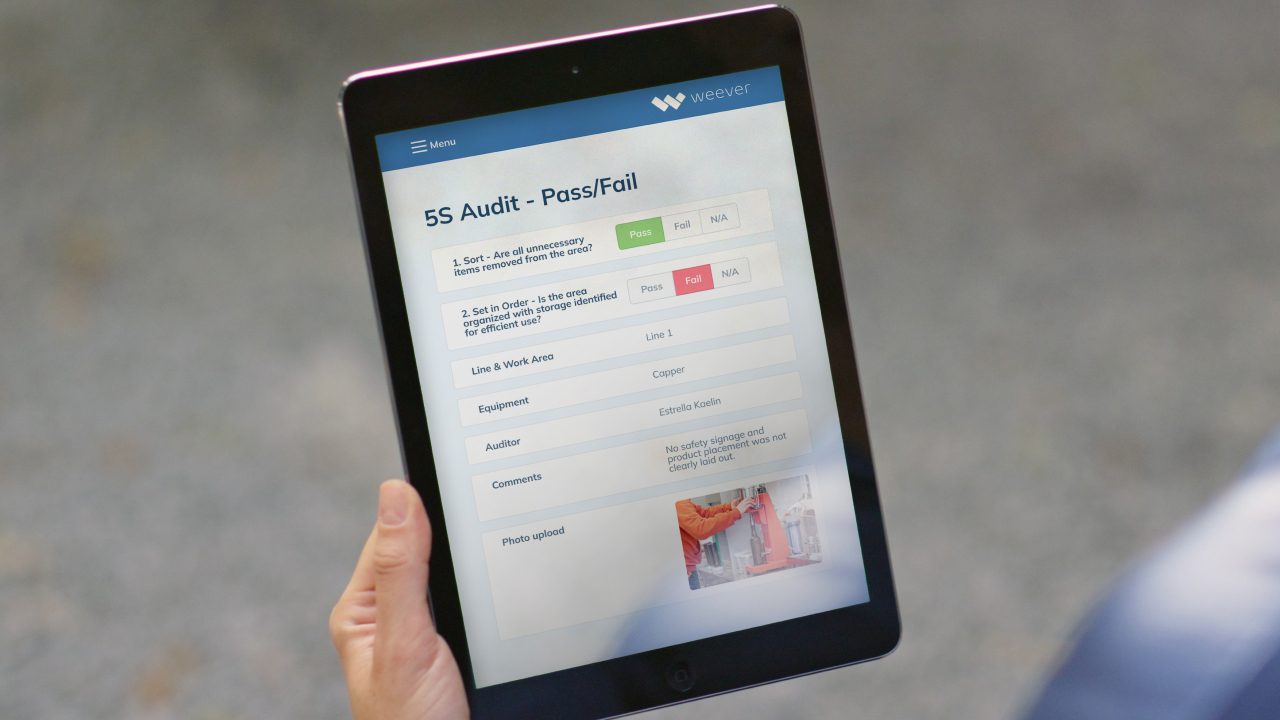

Creating an Effective Manufacturing Audit Checklist with Weever Software

Boost efficiency and productivity in manufacturing operations with Weever Software’s configurable program templates. Learn how to streamline workflows and enhance performance.

The Power of Program Templates in Manufacturing Operations: A Comprehensive Guide with Weever Software

Boost efficiency and productivity in manufacturing operations with Weever Software’s configurable program templates. Learn how to streamline workflows and enhance performance.

The Benefits of Standardized Program Templates in Manufacturing

The Benefits of Standardized Program Templates in Manufacturing Standardized program templates streamline manufacturing, enhance efficiency, and ensure consistency. Learn how Weever Software simplifies implementation with user-friendly, automated solutions. Efficiency and consistency are key to maintaining a competitive edge in manufacturing. The implementation of new programs and policies can often be a daunting task, requiring significant…