Digitize Everything.

Enhance safety, keep equipment and machines running, reduce product defects, track training, continuously improve, and ensure compliance.

- All Solutions

- Autonomous Maintenance

- Compliance

- Continuous Improvement

- Maintenance

- Production

- Quality

- Safety

- Total Productive Maintenance

- Training

- Warehouse

Near Miss Reporting

Assess the risk level of shifts and provide real-time instructions including safety walk requirements.

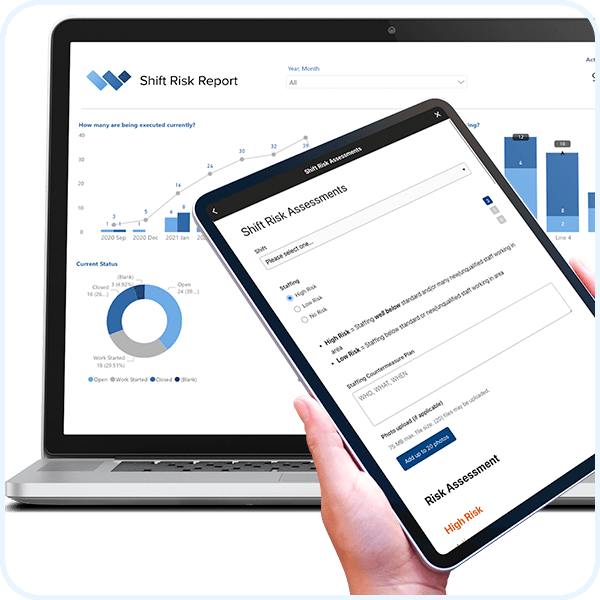

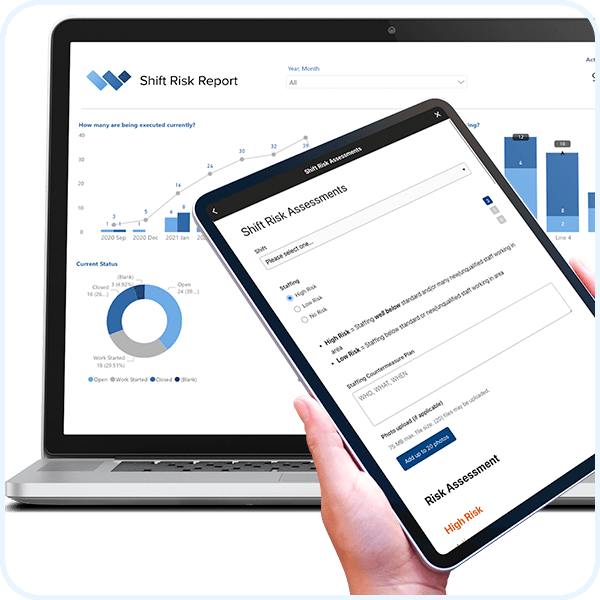

Pre-Shift Safety Risk Assessments

Assess the risk level of shifts and provide real-time instructions including safety walk requirements.

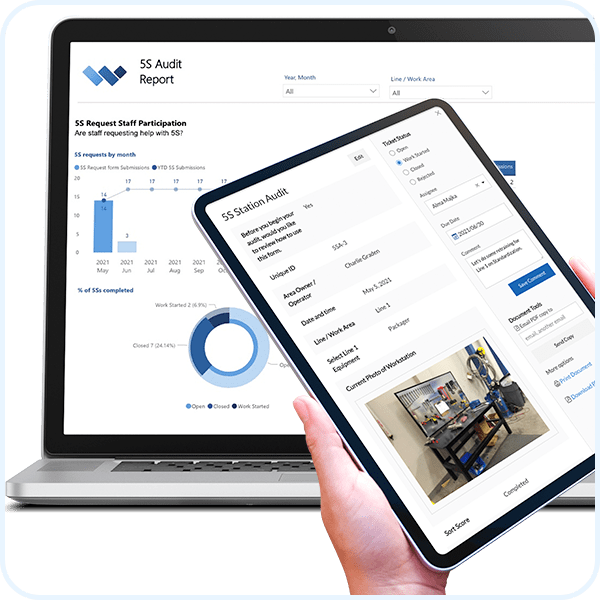

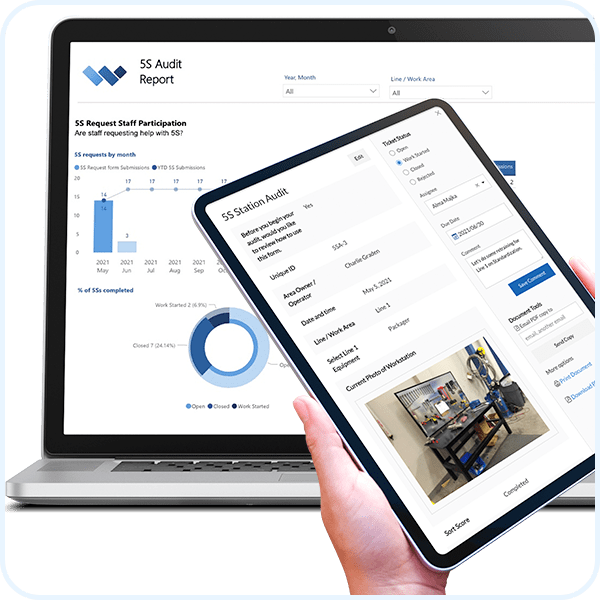

5S Workstation Optimization

Ensure workstations are optimized correctly and improvements are sustained by documenting Sort, Set in Order and Shine steps including photos and videos.

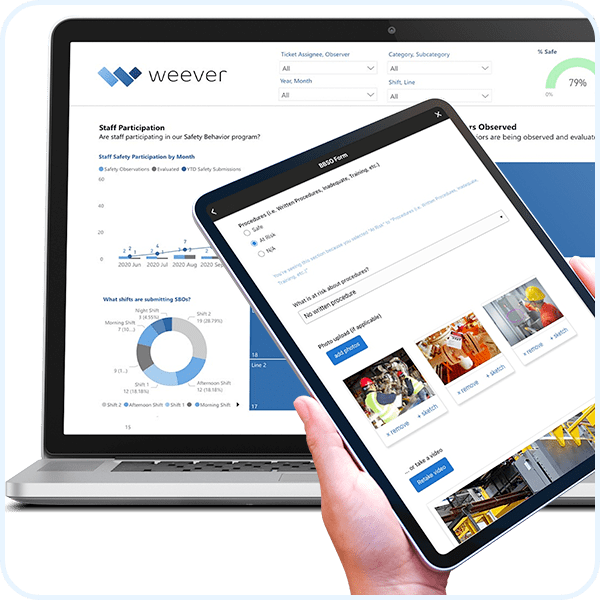

Behavior-Based Safety Observations

Erradicate 90% of facility safety incidents, which are caused by at-risk behaviors, not conditions.

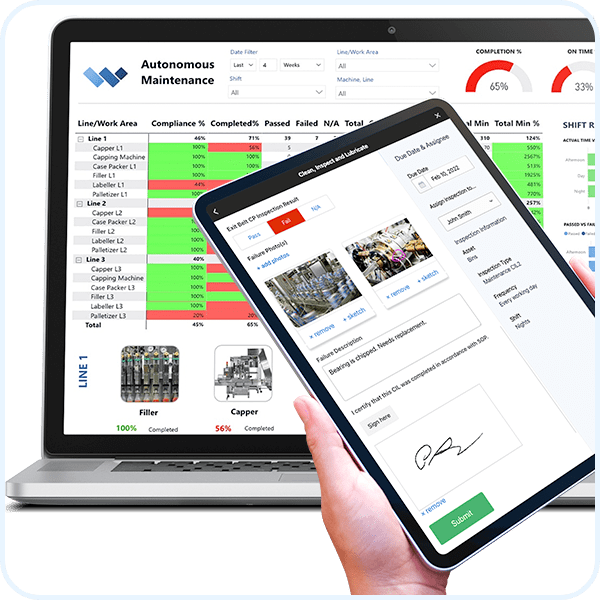

Autonomous Maintenance

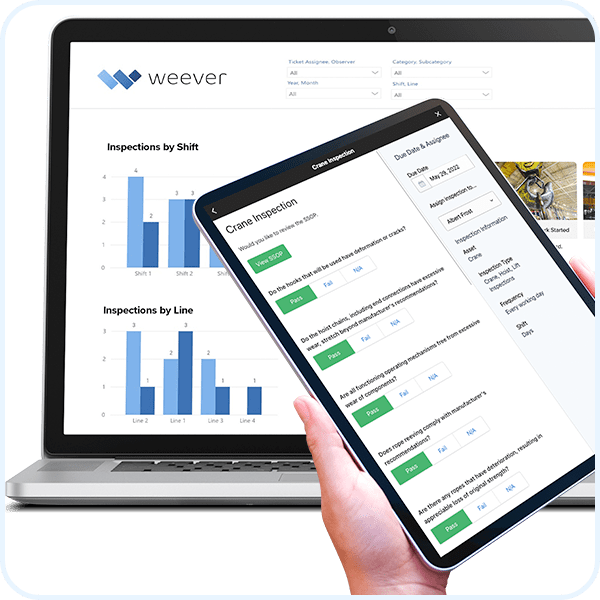

Provide cleaning, inspection and lubrication (CIL) instructions and manage schedules. Automatically escalate failed inspections.

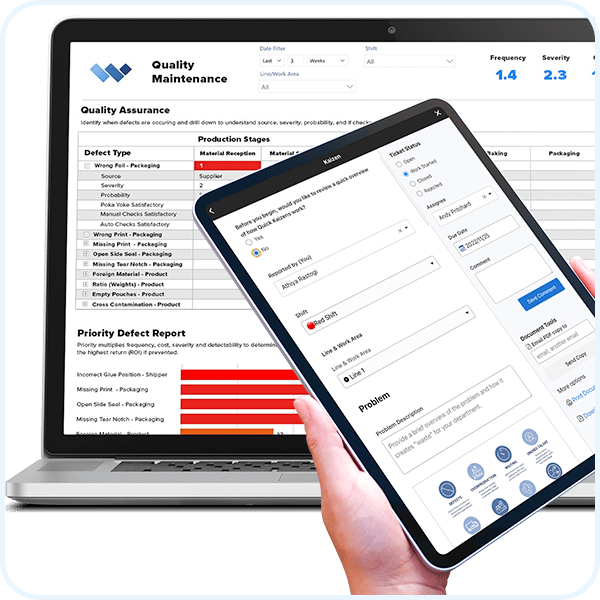

Quality Assurance Matrix

Understand and prevent quality defects within the context of Total Productive Maintenance (TPM).

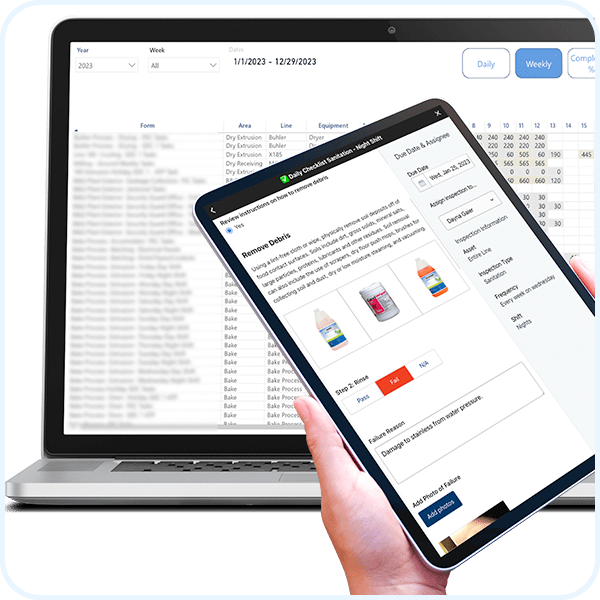

Production Line Cleaning & Sanitation Checklist

Set up your sanitation schedule your way and refine it as you go.

6S Lean: 5S + Safety

Ensure 6S Lean (5S + Safety) audits are completed correctly including photos or video capture.

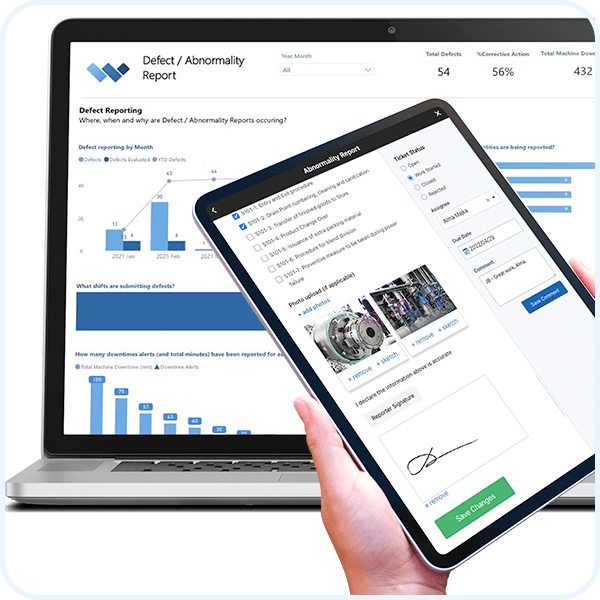

Abnormality Reporting

Make it easy for staff to report Process Abnormalities and for managers to initiate PDCA projects.

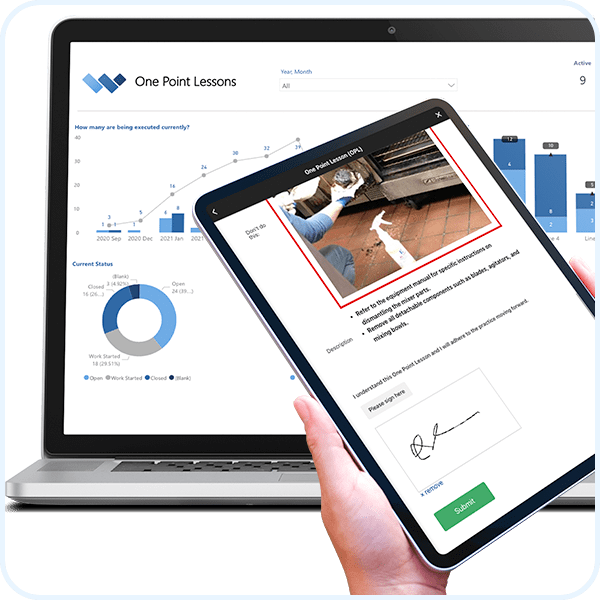

One Point Lessons (OPL)

Streamline and optimize your workplace with our user-friendly digital software solution for Lean One Point Lessons, improving efficiency, knowledge sharing, and problem-solving.

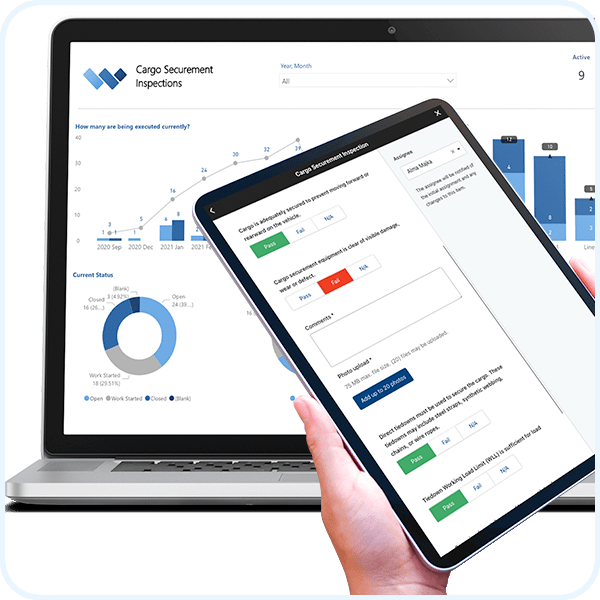

Cargo Securement Inspection

FMCSA best practices for warehouses is to maintain documentation that demonstrates compliance with cargo securement regulations.

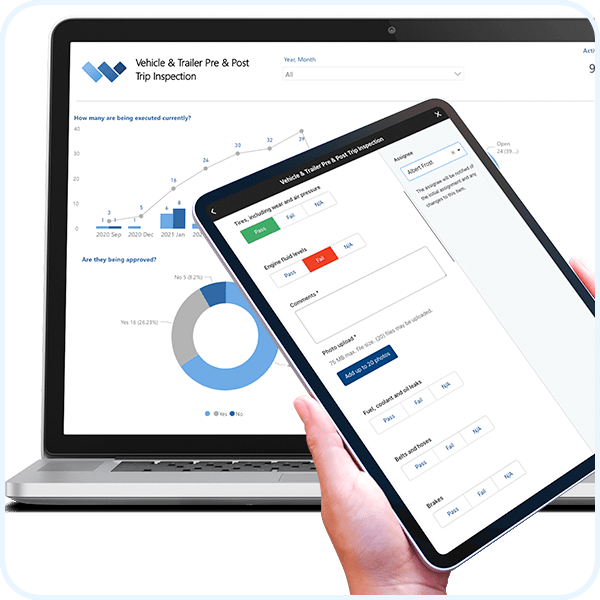

Vehicle & Trailer Pre & Post Trip Inspection

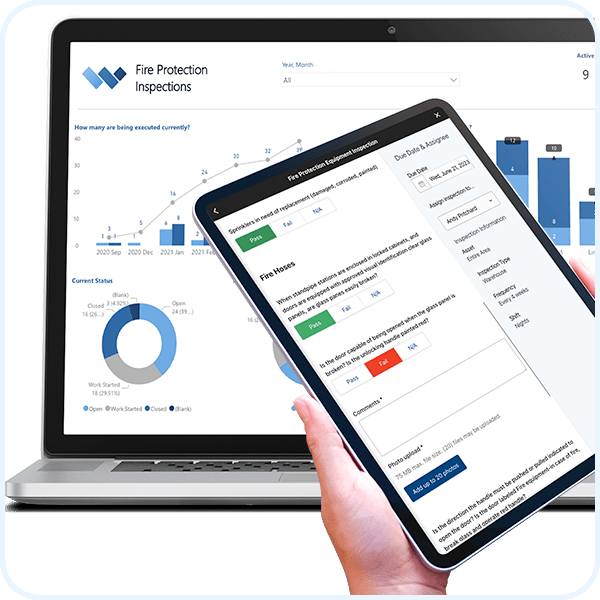

Digitize fire protection inspections to ensure they are completed correctly.

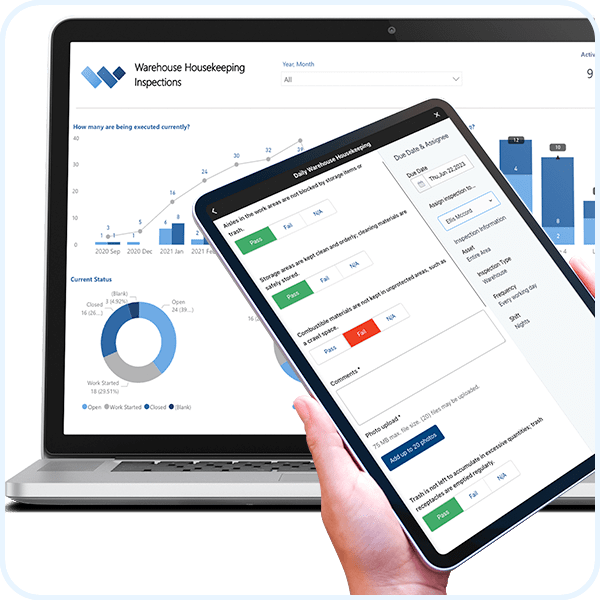

Warehouse Housekeeping Inspections

Inspect forklifts, pallet jacks, and other material handling equipment before each use to ensure proper functioning and safety.

“Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report.”

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

“It’s shifted our safety culture because now we are much more focused on what we should be looking at.”

Kody Crossen, Operations Manager of EHS