Uncategorized

Weever’s Configurable Templates Might Be the Best Tool in Your Toolbox

Weever’s Templates Might Be the Best Tool in Your Toolbox Every manufacturing operation is its own little universe with unique processes, challenges, and goals. September 2025 TABLE of contents Weever’s Program Templates Might Be the Best Tool in Your Toolbox Every manufacturing operation is its own little universe with unique processes, challenges, and goals. How…

Blog Template

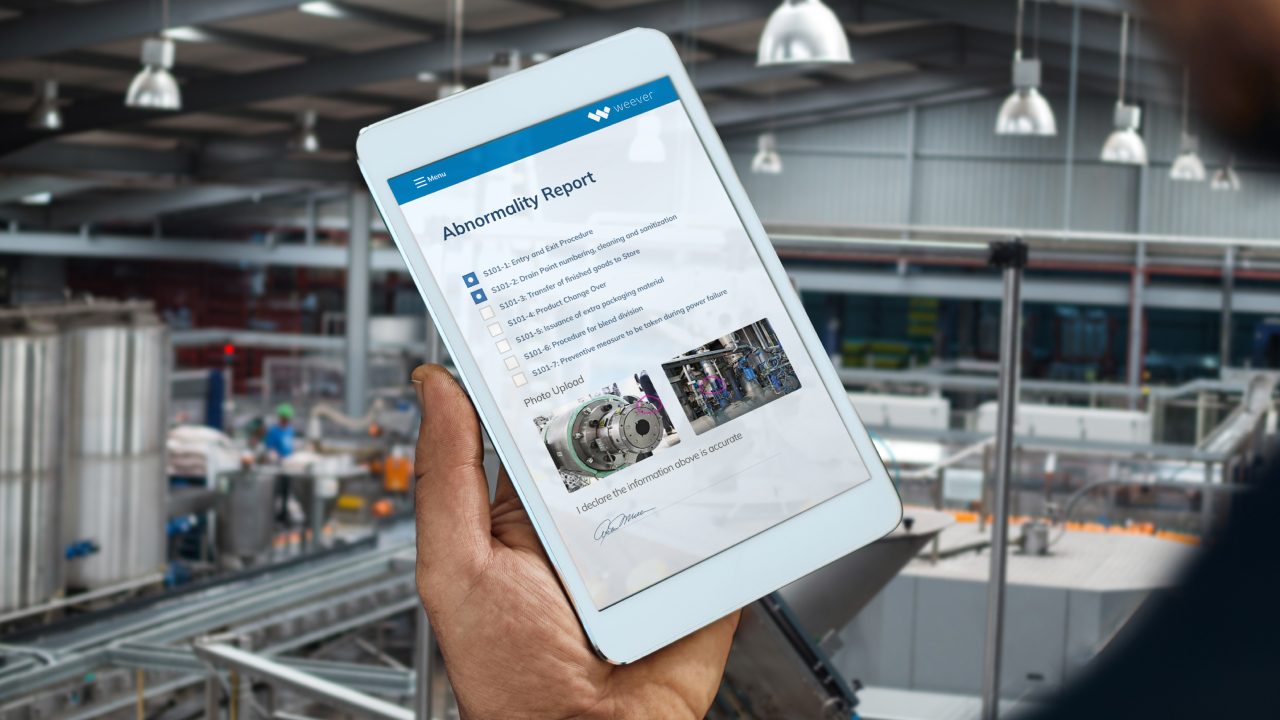

The Smart Connected Worker Platform Connecting Workers with Intelligent Solutions for Manufacturing Safety, Efficiency and Operational Excellence August 15 2025 Revolutionizing Manufacturing Operations The manufacturing industry stands at a critical juncture where traditional approaches meet cutting-edge technology. Our Smart Connected Worker Platform bridges this gap by providing workers with intelligent, real-time solutions that enhance decision-making,…

5S Ultimate Guide 5S Systems

Everything you need to know about how 5S works and the best practices gleaned from our 10+ years of experience helping organization achieve success.

Thank you – Weever Dashboard Brochure

A download link has been sent to the email address you provided. Tell us a bit about yourself. We work with organizations of all shapes and sizes from all over the world.

What Are Emerging Trends in Autonomous Maintenance, and How Can Weever Enhance Efficiency Across Industries?

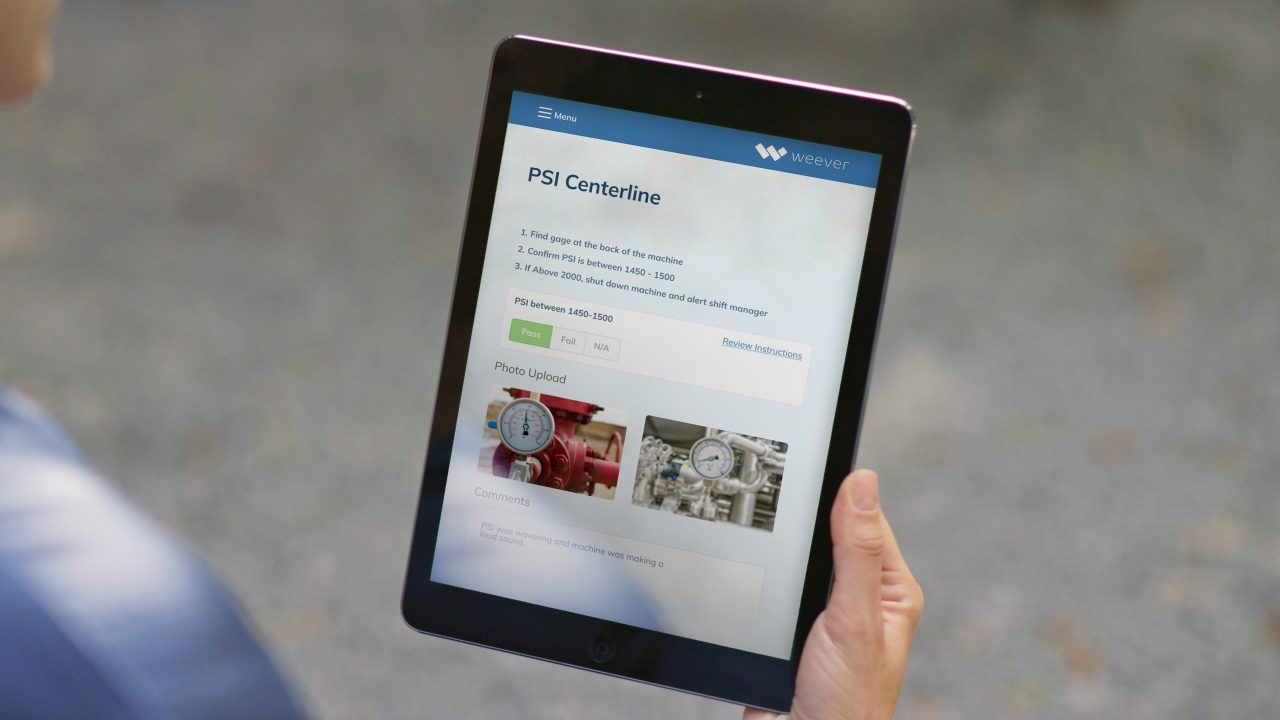

What Are Emerging Trends in Autonomous Maintenance, and How Can Weever Enhance Efficiency Across Industries? Discover emerging trends in autonomous maintenance and how Weever enhances efficiency across industries. Autonomous maintenance is rapidly evolving as industries seek ways to optimize operations, reduce downtime, and maintain a competitive edge. But what is autonomous maintenance? Autonomous maintenance refers…

How Can Leveraging Digital Transformation Enhance Autonomous Maintenance with Weever?

Leverage digital transformation with Weever to enhance Autonomous Maintenance. Simplify integration, automate workflows, gain insights, and improve efficiency.

When Autonomous Maintenance Occurs: Timing and Strategy with Weever’s Assistance

When Autonomous Maintenance Occurs: Timing and Strategy with Weever’s Assistance Discover when to perform autonomous maintenance and how Weever’s tools help businesses optimize timing, automate tasks, and stay ahead of industry trends. Autonomous maintenance, an essential pillar of Total Productive Maintenance (TPM), empowers operators to take charge of routine maintenance tasks such as cleaning, inspecting,…

How Does Autonomous Maintenance Serve as a Pillar for Continuous Improvement, and How Does Weever Strengthen This Foundation to Keep Businesses Ahead of Emerging Trends?

How Does Autonomous Maintenance Serve as a Pillar for Continuous Improvement, and How Does Weever Strengthen This Foundation to Keep Businesses Ahead of Emerging Trends? Discover how Weever strengthens Autonomous Maintenance to drive continuous improvement and keep your business ahead of industry trends. Autonomous Maintenance (AM) is one of the most crucial pillars in Total…

What Are the 7 Steps to Implementing Autonomous Maintenance, and How Does Weever Drive TPM on the Shop Floor to Keep Businesses Ahead of Emerging Trends?

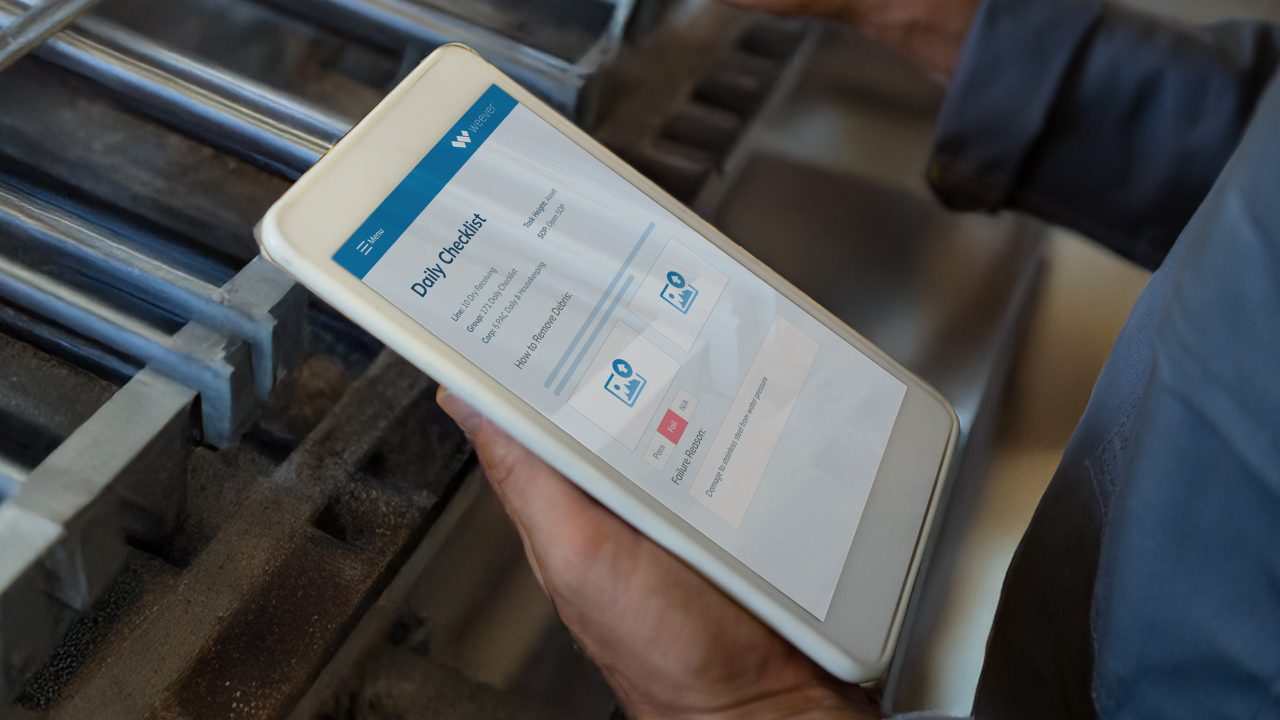

7 Steps to Implementing Autonomous Maintenance Simplify TPM on the shop floor for maximum efficiency. In the manufacturing world, staying competitive means constantly evolving processes, particularly in Total Productive Maintenance (TPM). Autonomous maintenance (AM), a key pillar of TPM, empowers machine operators to handle routine maintenance tasks. But what is autonomous maintenance, and how can…

Understanding TPM and Autonomous Maintenance: How Weever Supports Total Productive Maintenance

Understanding TPM and Autonomous Maintenance: How Weever Supports Total Productive Maintenance Learn how Weever simplifies TPM and autonomous maintenance, helping businesses boost efficiency, stay ahead of trends, and ensure long-term success. Maintaining operational efficiency and minimizing downtime are critical factors that can make or break a business in today’s competitive landscape. Total Productive Maintenance (TPM)…