AM

Achieving Operational Efficiency with Weever: Integrating Centerlining, CIL, and 5S Audits

Achieving Operational Efficiency with Weever: Integrating Centerlining, CIL, and 5S Audits Achieve operational efficiency with Weever. Integrate Centerlining, CIL, and 5S audits to automate workflows, reduce waste, and drive continuous improvement. Operational efficiency is more than just a buzzword-it’s a critical goal for manufacturers aiming to remain competitive in an increasingly demanding marketplace. Consistently producing…

Read MoreReducing Defects through Proactive Monitoring with Weever’s Abnormality and Defect Detection

Reducing Defects through Proactive Monitoring with Weever’s Abnormality and Defect Detection Reduce defects with Weever’s proactive monitoring. Detect abnormalities early, automate resolutions, and improve product quality with real-time insights. The smallest defect can have costly ripple effects in manufacturing operations, leading to product recalls, dissatisfied customers, and lost revenue. Manufacturers need a way to proactively…

Read MoreWeever’s Reporting Helps Identify and Manage Defects

Weever’s Reporting Helps Identify and Manage Defects Optimize manufacturing with Weever’s real-time abnormality and defect tracking. Detect issues early, resolve swiftly, and maintain high manufacturing standards. For manufacturers, early detection and swift management of defects are essential to maintaining quality and minimizing downtime. Left unchecked, even minor abnormalities can escalate, disrupting production lines and increasing…

Read MoreAchieving Process Stability through Centerlining with Weever

Achieving Process Stability through Centerlining with Weever Achieve process stability with Weever’s centerlining tools. Simplify data tracking, automate workflows, and maintain consistent, high-quality manufacturing output. In manufacturing, maintaining process stability is essential for producing consistent, high-quality products. One of the most effective ways to achieve this stability is through centerlining, a technique used to establish…

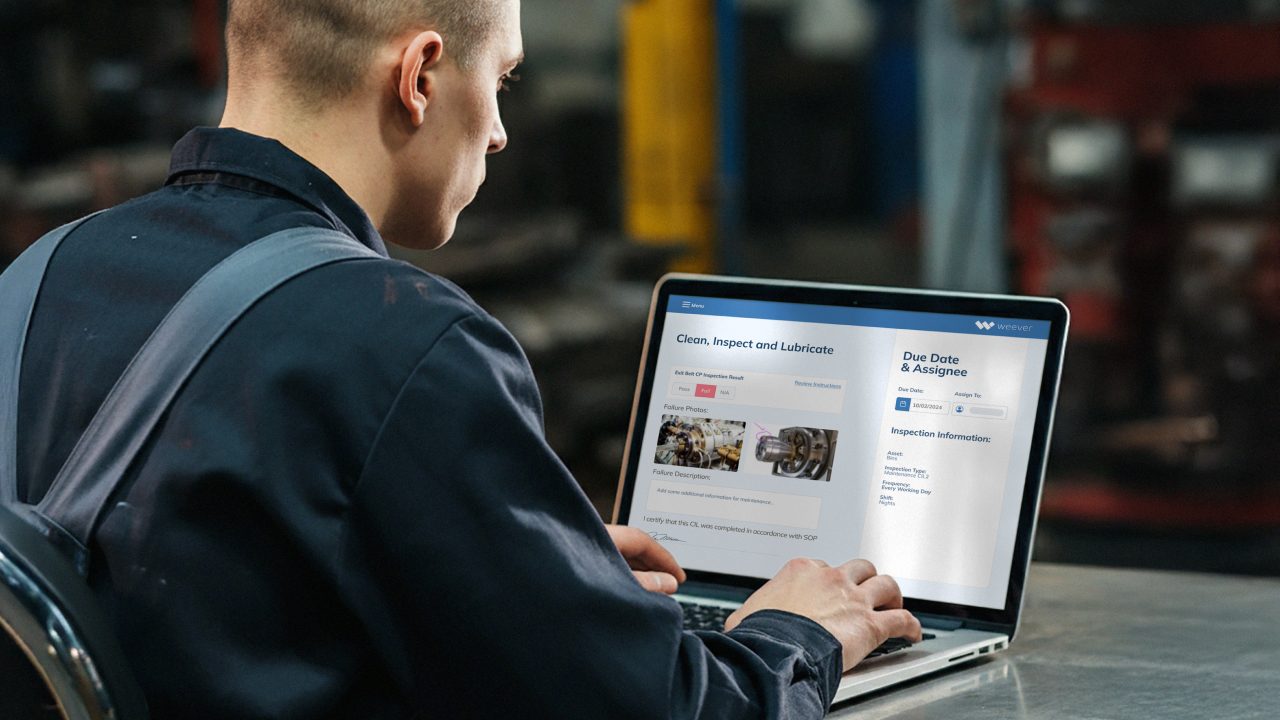

Read MoreStandardizing CIL Practices Across Your Organization Using Weever’s Digital Platform

Standardizing CIL Practices Across Your Organization Using Weever’s Digital Platform Learn how Weever helps standardize CIL practices across teams, automating workflows and improving maintenance consistency for better equipment performance. In the manufacturing industry, maintaining equipment through Cleaning, Inspection, and Lubrication (CIL) routines is essential for maximizing productivity and preventing breakdowns. However, without standardized CIL practices,…

Read MoreStreamlining Clean, Inspect, Lubricate (CIL) Processes with Weever: Boosting Maintenance Efficiency

Streamlining Clean, Inspect, Lubricate (CIL) Processes with Weever: Boosting Maintenance Efficiency Boost maintenance efficiency with Weever’s digital platform. Streamline CIL, automate workflows, and gain data-driven insights across your organization. For manufacturers, maintaining equipment uptime and performance is critical to staying competitive. Effective Clean, Inspect, Lubricate (CIL) processes ensure equipment remains in peak condition, minimizing downtime…

Read MoreAutomating CIL Workflows with Weever: Saving Time and Reducing Manual Errors

Automating CIL Workflows with Weever: Saving Time and Reducing Manual Errors Boost maintenance efficiency with Weever’s automated CIL workflows. Save time, reduce errors, and streamline equipment upkeep for peak manufacturing performance. Maximizing equipment uptime and performance is essential for manufacturers. Effective Clean, Inspect, Lubricate (CIL) routines are vital to this maintenance, but managing them manually…

Read MoreHow Weever Simplifies Abnormality Detection and Resolution for Manufacturers

How Weever Simplifies Abnormality Detection and Resolution for Manufacturers Optimize manufacturing efficiency with Weever’s digital abnormality and defect detection. Streamline reporting, automate workflows, and resolve issues faster. Maintaining operational efficiency means promptly identifying and resolving abnormalities and defects before they escalate into costly disruptions. However, with complex workflows and the constant drive to maximize output,…

Read MoreTracking and Reporting Abnormalities and Defects in Real-Time with Weever

Tracking and Reporting Abnormalities and Defects in Real-Time with Weever Optimize manufacturing with Weever’s real-time abnormality and defect tracking. Detect, report, and resolve issues instantly to minimize disruptions and enhance efficiency. Identifying and addressing abnormalities and defects quickly is essential to maintaining smooth operations and high-quality standards for manufacturers. Delays in resolving issues can disrupt…

Read MoreOperator-Led CIL Training with Weever: Bridging Knowledge Gaps Across Different Manufacturing Industries

Operator-Led CIL Training with Weever: Bridging Knowledge Gaps Across Different Manufacturing Industries Discover how Weever simplifies operator-led CIL training to bridge knowledge gaps, ensuring consistent, efficient maintenance across manufacturing industries. In the manufacturing industry, keeping equipment in optimal working condition is crucial for maintaining operational efficiency. Cleaning, Inspection, and Lubrication (CIL) routines are a core…

Read More