Sanitation Management

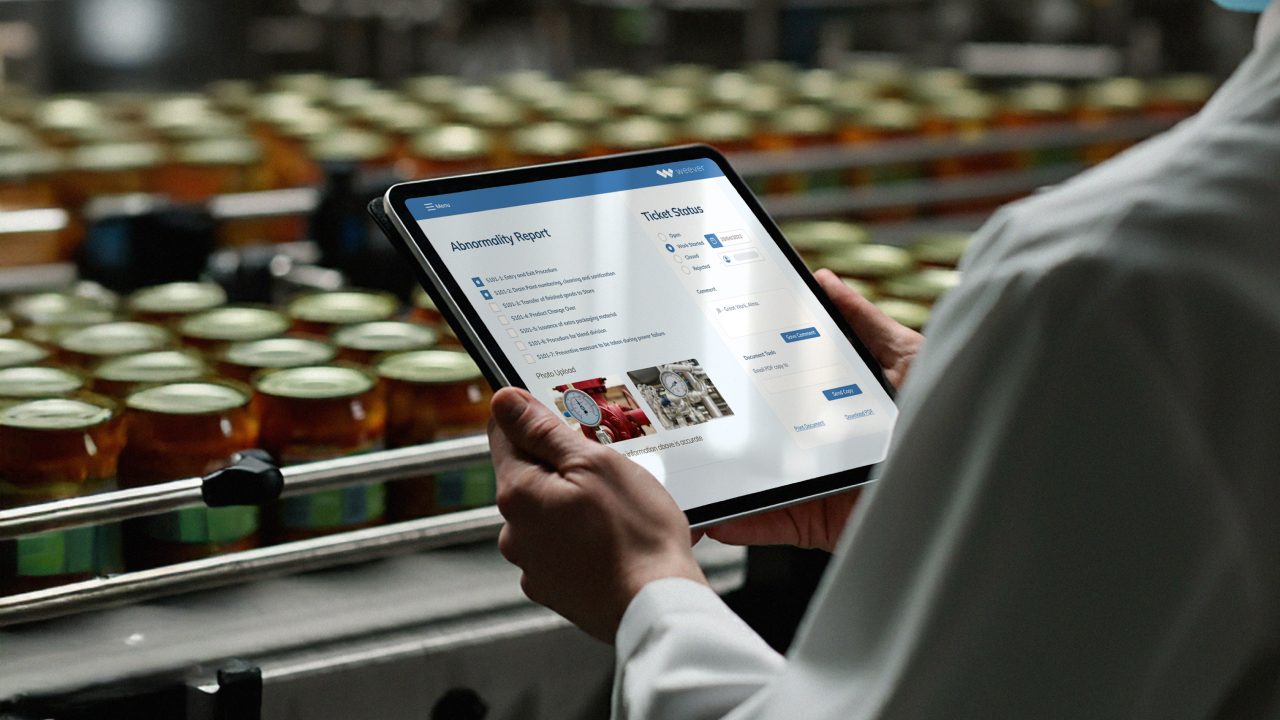

How can a food safety compliance management platform keep manufacturing operations risk-free?

How can a food safety compliance management platform keep manufacturing operations risk-free? Discover how Weever’s food safety compliance platform streamlines processes, automates tasks, and minimizes risks for safe, efficient manufacturing operations. Food safety is a non-negotiable aspect of the food manufacturing industry. The consequences of lapses in compliance can range from product recalls and reputational…

Read MoreWhat Should a Master Cleaning Schedule Include, and How Can Weever Software Help You Stay Compliant and Efficient?

What Should a Master Cleaning Schedule Include, and How Can Weever Software Help You Stay Compliant and Efficient? Learn what a master cleaning schedule should include and how Weever software simplifies compliance, efficiency, and task automation in cleaning operations. A master cleaning schedule is essential for maintaining cleanliness, ensuring safety, and achieving compliance in industries…

Read MoreHow Does Weever Software Help Manufacturers Overcome Common Challenges in Master Sanitation Schedules?

How Does Weever Software Help Manufacturers Overcome Common Challenges in Master Sanitation Schedules? Overcome MSS challenges with Weever! Simplify sanitation schedules, automate workflows, gain real-time insights, and ensure compliance in food manufacturing. Maintaining cleanliness and compliance is a critical yet complex task for manufacturers. A Master Sanitation Schedule (MSS) forms the backbone of this effort,…

Read MoreHow Does Weever Software Drive Innovation and Compliance in Food and Beverage Manufacturing with Configurable Sanitation Programs?

How Does Weever Software Drive Innovation and Compliance in Food and Beverage Manufacturing with Configurable Sanitation Programs? Boost food manufacturing safety and innovation with Weever’s configurable sanitation programs. Simplify compliance, automate tasks, and adapt to changing needs. The food and beverage manufacturing industry operates in a high-stakes environment where innovation and compliance must go hand…

Read MoreHow Can Food and Beverage Manufacturers Scale Operations Without Compromising Sanitation Standards Using Weever Software?

How Can Food and Beverage Manufacturers Scale Operations Without Compromising Sanitation Standards Using Weever Software? Scale food and beverage manufacturing confidently with Weever. Maintain sanitation standards with automated workflows, real-time insights, and seamless integration. Scaling operations is an exciting milestone for food and beverage manufacturers, but it comes with its own set of challenges. As…

Read MoreHow Does Weever Software Support Quality Assurance Through Planned Cleaning in Food Manufacturing?

How Does Weever Software Support Quality Assurance Through Planned Cleaning in Food Manufacturing? Streamline planned cleaning in food manufacturing with Weever. Simplify MSS management, automate workflows, and ensure compliance for quality assurance. Quality assurance is a cornerstone of success in the food and beverage manufacturing industry. Ensuring product safety, maintaining compliance, and meeting customer expectations…

Read MoreWhy is Weever Software Essential for Aligning Sanitation Scheduling with Autonomous Maintenance in Manufacturing?

Why is Weever Software Essential for Aligning Sanitation Scheduling with Autonomous Maintenance in Manufacturing? Streamline sanitation and maintenance with Weever software. Align schedules, automate workflows, and boost efficiency in manufacturing. Aligning sanitation scheduling with autonomous maintenance is critical for maintaining efficiency and compliance. Autonomous maintenance empowers operators to take ownership of routine equipment upkeep, while…

Read MoreHow Does Weever Software Help Manufacturing Plants Achieve Audit Readiness with Master Sanitation Schedules?

How Does Weever Software Help Manufacturing Plants Achieve Audit Readiness with Master Sanitation Schedules? Achieve audit readiness with Weever! Streamline master sanitation schedules, automate workflows, and ensure compliance in food and beverage manufacturing. Maintaining a clean and compliant production environment is non-negotiable in food and beverage manufacturing. A well-executed Master Sanitation Schedule (MSS) is essential…

Read MoreHow Does Weever Software Enhance Food Safety and Support Autonomous Maintenance in Manufacturing?

How Does Weever Software Enhance Food Safety and Support Autonomous Maintenance in Manufacturing? Enhance food safety and equipment reliability with Weever’s master sanitation schedules and autonomous maintenance programs. Food safety and equipment reliability are critical in manufacturing environments, particularly in the food and beverage sector where contamination risks and downtime can significantly impact operations. To…

Read MoreHow a Smart Sanitation Schedule Transforms Food Manufacturing

How a Smart Sanitation Schedule Transforms Food Manufacturing Explore how Weever’s configurable MSS boosts food manufacturing efficiency and compliance. Food manufacturers operate in a high-stakes environment, where a single misstep in sanitation can lead to severe consequences. From costly product recalls and damaged brand reputations to potential health risks for consumers, the cost of non-compliance…

Read More