The Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency

Enhance manufacturing with predictive maintenance. Learn how Weever's software integrates data collection and analysis to not only prevent, but predict equipment failures.

Predictive maintenance is a game-changer in the manufacturing industry. Unlike traditional reactive maintenance, which fixes problems after they occur, predictive maintenance anticipates issues before they happen.

This approach uses data from sensors and machines to predict when maintenance is needed, keeping equipment running smoothly and efficiently. However, sensors may not be needed in all cases, so long as enough data is collected about machine operation and their maintenance cycles over long periods of time. Efficiency is crucial in manufacturing. Downtime can be costly, and unexpected equipment failures can halt production. Predictive maintenance helps avoid these issues by allowing manufacturers to perform maintenance at the right time, reducing downtime, and extending the life of equipment.

Weever's software plays a vital role in this transformation. By providing a unified platform for data collection and analysis, Weever enables manufacturers to gather and analyze real-time data from their machines, generating predictive maintenance insights. Weever helps manufacturers stay ahead of potential issues, ensuring their operations run efficiently and effectively.

Understanding Predictive Maintenance for Manufacturing

Predictive maintenance is a proactive approach that uses data and technology to predict when equipment will need upkeep. This method helps prevent unexpected failures and keeps manufacturing processes running smoothly.

Key Components of Predictive Maintenance for Manufacturing

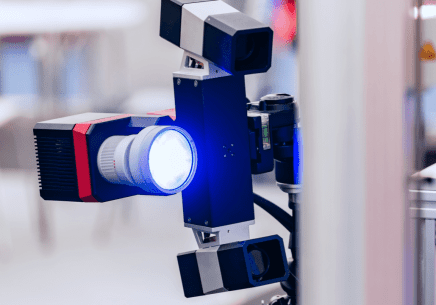

- Sensors: These devices are installed on machines to monitor their condition in real-time. They collect data on various parameters like temperature, vibration, and performance.

- Data Collection: The data gathered by sensors is stored and organized, providing a comprehensive view of the machine’s health.

- Data Analysis: Advanced software, such as artificial intelligence systems, analyzes the collected data, along with all historical data, to identify patterns and predict when maintenance will be needed.

Differences Between Predictive Maintenance and Other Maintenance Strategies for Manufacturers

- Reactive Maintenance: Fixing equipment after it breaks down. This approach can lead to unexpected downtime and higher costs.

- Preventive Maintenance: Performing regular, scheduled maintenance regardless of equipment condition. While better than reactive, it can still be inefficient and costly.

- Predictive Maintenance: Using real-time data to predict and perform maintenance only when necessary. This method is the most efficient, reducing downtime and extending equipment life.

By understanding and implementing predictive maintenance, manufacturers can achieve greater efficiency, save on costs, and maintain smooth operations.

The Role of Industrial IoT and Data Analytics in Manufacturing

Industrial IoT (Internet of Things) refers to the network of connected devices and sensors used in manufacturing and other industries. These IoT devices collect real-time data from machines and equipment, providing valuable insights into their performance and condition. By collecting vast amounts of data over time, patterns begin to emerge that analysis systems can detect.

How IoT devices collect real-time data:

- Sensors attached to machinery monitor various parameters like temperature, vibration, and usage.

- This data is transmitted instantly to a central system for analysis, such as the Weever platform.

Use of data analytics:

- Data analytics processes the real-time data from IoT devices to identify patterns and trends.

- By analyzing this data, the system can predict equipment failures and determine maintenance needs before issues arise.

Examples of IoT and data analytics in predictive maintenance:

- A sensor detects unusual vibrations in a motor, indicating potential wear. Data analytics predicts when the motor will likely fail, allowing for timely maintenance.

- Temperature sensors on a production line identify overheating components. The system alerts maintenance teams to address the issue before it leads to a breakdown.

By leveraging Industrial IoT and data analytics, manufacturers can enhance predictive maintenance, reduce downtime, and ensure smoother operations. Weever’s software can help integrate all of this data and analyze it, providing a powerful tool for modern manufacturing efficiency.

Implementing Predictive Maintenance in Manufacturing

Transitioning from reactive to predictive maintenance can significantly improve efficiency and reduce downtime in manufacturing. Here are the key steps to make this transition:

Assess Current Maintenance Strategies:

- Evaluate your existing maintenance practices to identify areas for improvement.

- Understand the limitations of reactive and preventive maintenance.

Select the Right Tools and Software:

- Choose software that supports predictive maintenance and integrates well with your existing systems.

- Ensure the tools include real-time data collection and advanced analytics capabilities.

Train Staff and Build Expertise:

- Provide comprehensive training for your team to effectively use the new predictive maintenance tools.

- Develop internal expertise to interpret data and act on insights.

Importance of Configurability in Manufacturing Settings

Weever’s software offers highly configurable forms, allowing you to tailor the system to your specific needs. This flexibility ensures that the predictive maintenance strategy aligns perfectly with your operational requirements, maximizing its effectiveness. Every manufacturing operation is unique, so the ability to adjust and configure maintenance forms and processes is essential. Configurable software is crucial for tailored implementation.

By following these steps and utilizing Weever’s configurable solutions, manufacturers can smoothly transition to predictive maintenance, enhancing overall productivity and operational efficiency.

Predictive maintenance is transforming manufacturing by preventing equipment failures and reducing downtime. By using data and technology to predict maintenance needs, manufacturers can improve efficiency and extend equipment life. Weever's software supports this by providing a unified platform for data collection and analysis, enabling real-time insights and proactive maintenance. Transitioning to predictive maintenance with Weever’s configurable solutions ensures tailored implementation, maximizing operational efficiency and productivity. Embrace predictive maintenance to stay ahead in the competitive manufacturing landscape.

Discover How Predictive Maintenance Can Transform Your Manufacturing Efficiency!

Discover How Predictive Maintenance Can Transform Your Manufacturing Efficiency – Click to Learn More!

Continue Reading

"Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report."

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

"It's shifted our safety culture because now we are much more focused on what we should be looking at."

Kody Crossen, Operations Manager of EHS