Business Solutions Lead

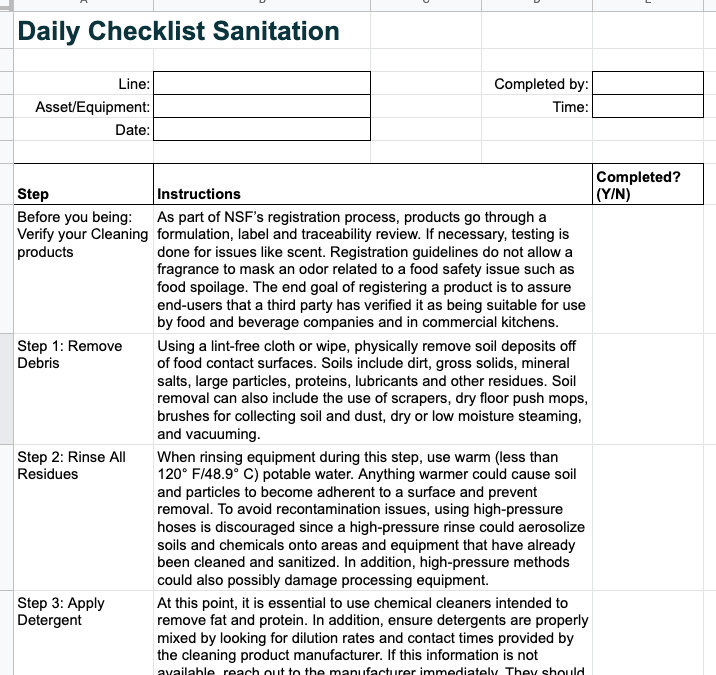

Free Food Production Line Sanitation Daily Checklist (.xlsx)

Download a free spreadsheet template for Food Production Line Sanitation Daily Checklist.

Read MoreThe 7 Steps of Cleaning & Sanitizing food production lines

Regulatory bodies and food safety programs worldwide have their own slightly varied versions for properly cleaning and sanitizing food contact surfaces and equipment. However, this list, provided by the NSF overviews the most commonly suggested steps among the different renditions.

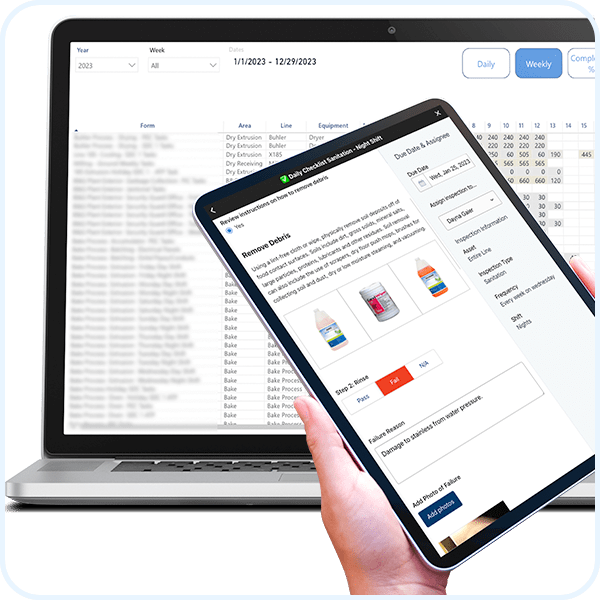

Read MoreHow software will optimize your sanitation program

Over the past 10 years, Weever has been on the front lines of helping global Fortune 100 manufacturing companies implement and maintain successful 5S programs. We’ve learned a lot from our clientele over the years and we’re happy to share those lessons here.

Read MoreTop 10 best practices of Sanitation in Food Processing

Over the past 10 years, Weever has been on the front lines of helping global Fortune 100 manufacturing companies implement and maintain successful 5S programs. We’ve learned a lot from our clientele over the years and we’re happy to share those lessons here.

Read MoreOverview of Food Production Sanitation Regulations

In response to a growing number of foodborne illness outbreaks, the Food Safety Modernization Act (FSMA) of 2011 shifted the focus from responsive contamination management to preventing food safety problems before they occur and recognizes the importance of strong foodborne illness and outbreak surveillance systems.

Read MoreProduction Line Cleaning & Sanitation Types

Cleaning and sanitation programs are the backbone of creating a safe plant environment for employees and for the food it produces.

Food processing and packaging equipment accumulate grease, carbonized residue, seasonings, proteins, harmful bacteria, biofilms, adhesives, labels, and many other contaminants that traditionally take significant time to clean.

Thank you for requesting the Sanitation Guide

A download link has been sent to the email address you provided. Tell us a bit about yourself. We work with organizations of all shapes and sizes from all over the world and we can help you as well. Everything you need to get Sanitation done. Radically improve the efficacy of your sanitation program by…

Read MoreFood Plant Sanitation Ultimate Guide

This guide is for managers at food and beverage manufacturing organizations that are looking for ways to optimize their cleaning and sanitation program. For those who are new to sanitation, the guide provides an overview of the landscape including useful definitions, cleaning steps, and regulations.

For experienced veterans, we have included detailed instructions on how to optimize your program and some best practices we have recognized from our 10 years of experience helping organizations automate core processes and empower staff.

Master Sanitation Schedules

Set up your sanitation schedule your way and refine it as you go.

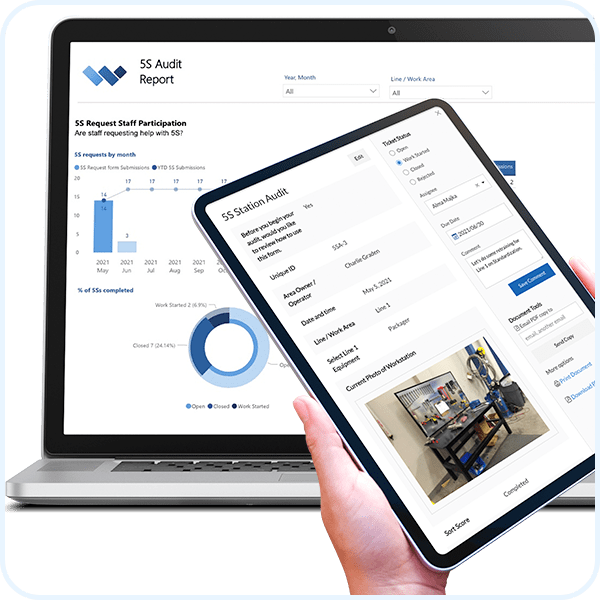

Read More6S Lean: 5S + Safety

Ensure 6S Lean (5S + Safety) audits are completed correctly including photos or video capture.

Read More