5S

5S Audit Digitization Benefits

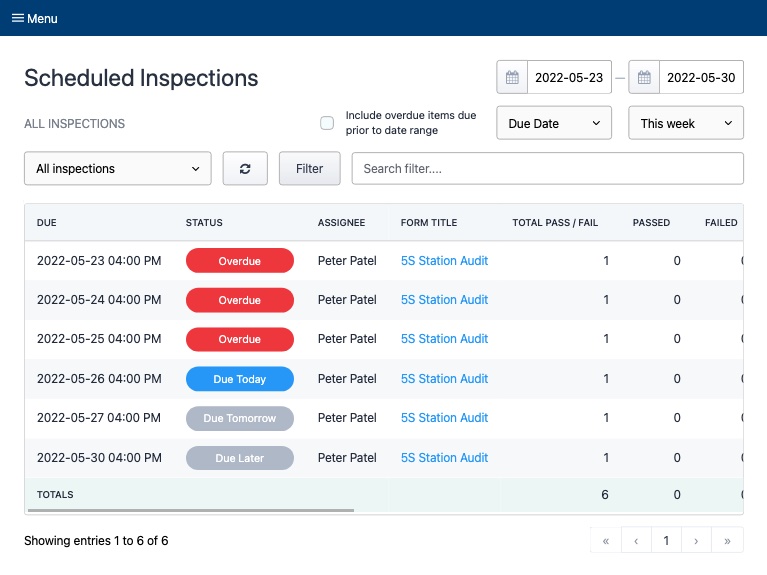

To ensure the sustained success of a 5S program, CI Managers need an efficient way to schedule and assign 5S audits and other related events. Let’s explore how automated digital schedules will help you maximize the impact of your 5S program.

Read MoreHow to build your 5S Digitization Project Plan

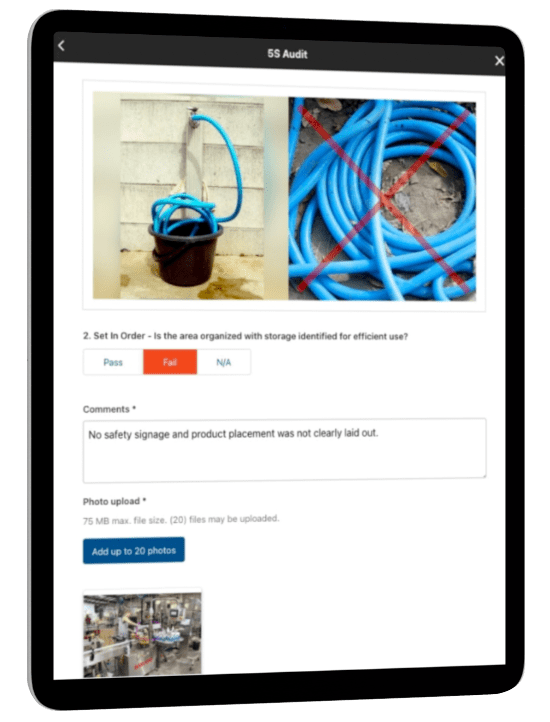

It’s time to take your 5S audit to the next level by digitizing the process. This blog post will guide you through the steps to digitize your 5S audit while making the journey both professional and fun!

Read MoreTop 5S benefits for manufacturing companies

The 5S methodology can have a significant positive impact on many success factors for your business, including efficiency gains, enhanced safety and quality, improvements to employee engagement and moral, cost savings and continuous improvement.

Read MoreIs 5S right for you?

If you are uncertain whether 5S is right for your facility askyourself and your team the following questions.If the answer was “yes” to one or more of these questionsyou may find 5S to be very beneficial to your organization.

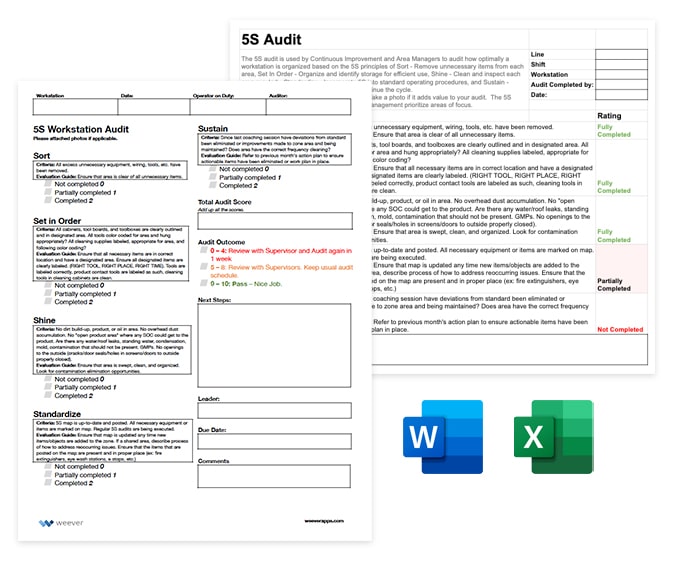

Read MoreFree 5S Audit Form Templates

Download a free 5S Audit Spreadsheet template you can adapt to your unique requirements.

Read More5S Audit Scorecard

Download a free 5S Audit Spreadsheet template you can adapt to your unique requirements.

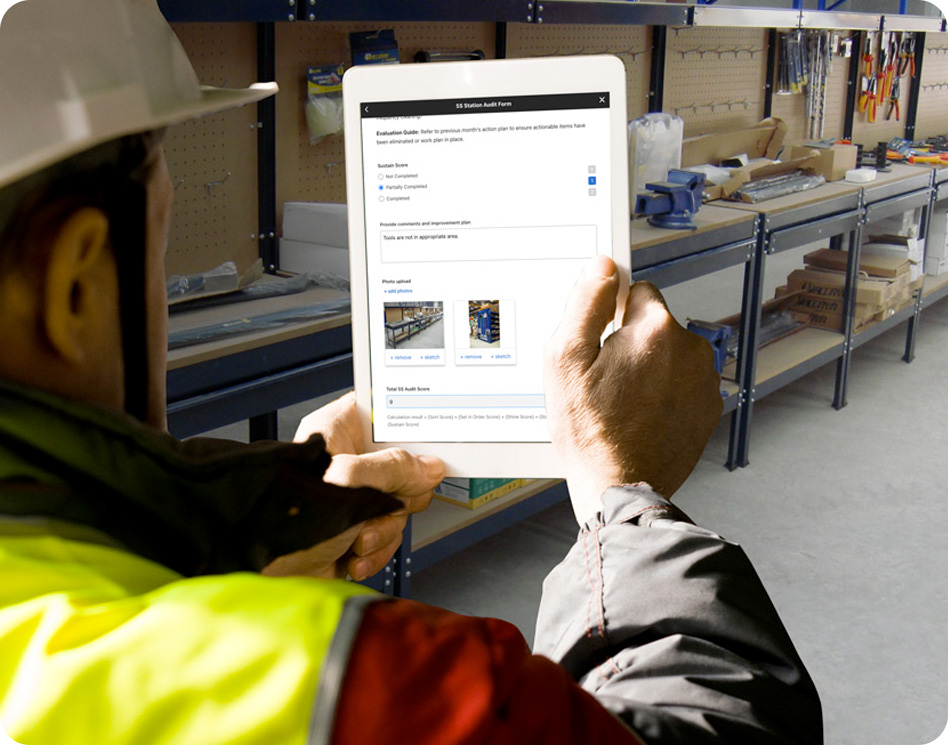

Read More5S Audit Scorecard: How to Score a 5S Audit With Weever

A 5S audit serves as a litmus test for how effectively an organization has embraced the principles of 5S. Achieving a high score in this audit signifies a commitment to excellence, efficiency, and continuous improvement. The 5th “S” stands for Sustain (Shitsuke), which is a long term proposition that involves regular auditing and training.

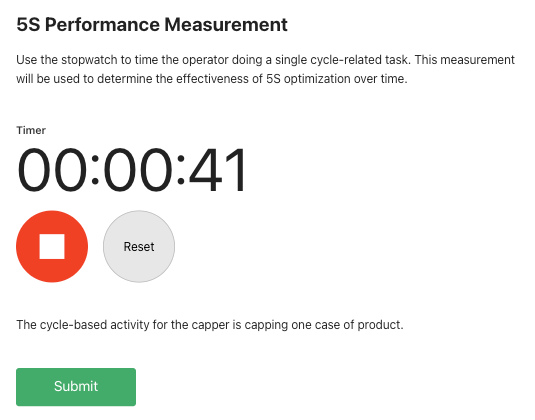

Read MoreMeasure the Real Impact of your 5S Audits with Cycle-based Activity Timing

Cycle time is the duration of one production cycle, and it can be used as a metric to identify improvement opportunities in a manufacturing process. By measuring cycle time, managers can identify bottlenecks, waste, and inefficiencies, and develop strategies to improve the process.

Read More5S Auditing Best Practices

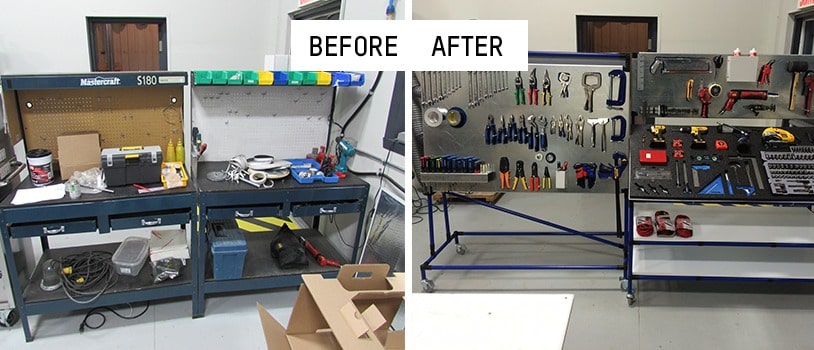

A crucial part of Sustain is completing regular 5S Audits, which help maintain gains from your 5S Action Plan and also find new ways to make your workstations more efficient, safe, and productive over time.

Read More5S Overview – What is it?

In order to be profitable and compete in a global market every company has to effectively steward its resources. It’s been said that waste is a thief. In manufacturing, where waste can take several different forms including wasted time, energy, movement, or materials, this is especially true.

Read More