Why do 5S?

Is 5S right for your manufacturing organization?

Andy Pritchard | August 20, 2023 | 7 min read

5S Overview

5S Planning

5S Implementation

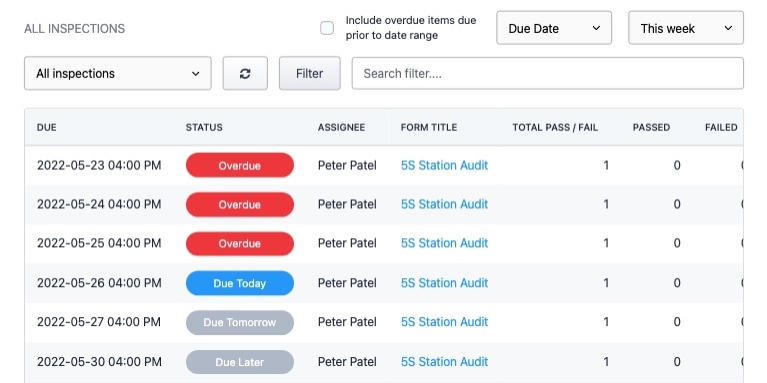

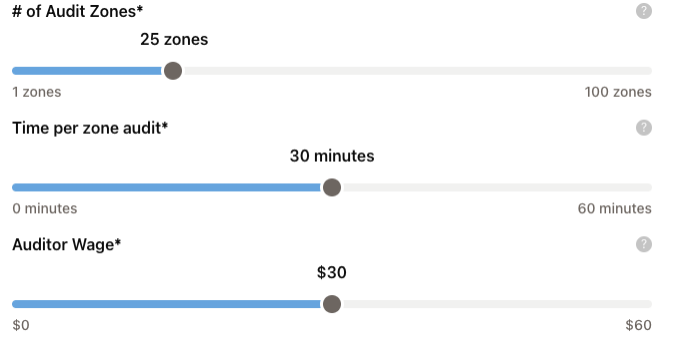

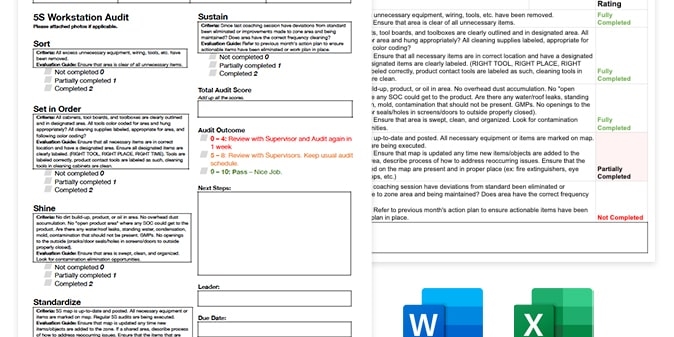

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Implementing the 5S lean methodology is a strategic move that can revolutionize your manufacturing organization in terms of efficiency, productivity, and overall profitability. The 5S methodology, derived from Japanese principles, stands for Sort, Set in order, Shine, Standardize, and Sustain. Its benefits are not merely theoretical; they are grounded in proven facts that have transformed countless manufacturing facilities worldwide.

First and foremost, 5S improves workplace organization and cleanliness, leading to a safer and more pleasant work environment for your employees. Studies have consistently shown that cleaner, well-organized workplaces reduce the likelihood of accidents and injuries, thereby reducing workers' compensation claims and downtime. Additionally, an orderly workspace promotes employee morale and engagement, enhancing overall job satisfaction and retention rates.

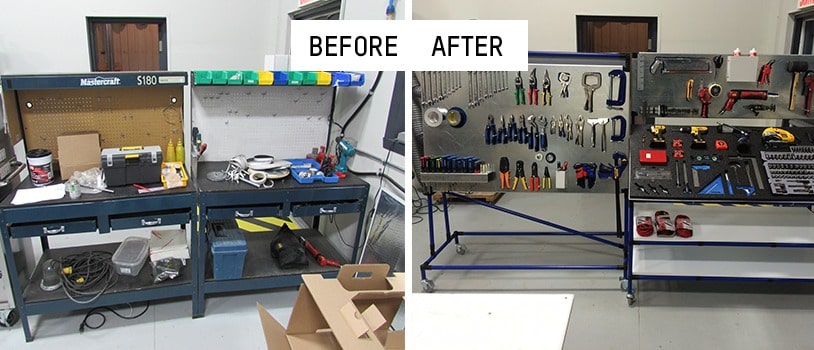

Furthermore, 5S streamlines your manufacturing processes, resulting in reduced waste and increased efficiency. By eliminating unnecessary items (Sort), arranging tools and materials for easy access (Set in order), and maintaining equipment (Shine), you'll minimize downtime and maximize productivity. Standardizing these processes ensures consistency and quality, while sustaining 5S practices ensures continuous improvement over time. Manufacturers who have embraced 5S have reported significant cost savings, reduced lead times, and higher product quality, all of which contribute directly to your bottom line.

In today's competitive market, customer satisfaction is paramount, and 5S plays a pivotal role in meeting and exceeding customer expectations. With a well-organized and efficient manufacturing process, you can deliver products on time and with consistently high quality, fostering customer loyalty and positive word-of-mouth referrals. The 5S methodology is not just a trend; it's a proven framework that can enhance your manufacturing organization's performance, safety, and profitability. It's time to embark on this journey toward operational excellence and secure a brighter future for your company.

Is 5S right for you?

If you are uncertain whether 5S is right for your facility ask yourself and your team the following questions. If the answer was “yes” to one or more of these questions you may find 5S to be very beneficial to your organization.

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo