AM

What are the Benefits of Autonomous Maintenance, and How Does Weever Drive Results?

What are the Benefits of Autonomous Maintenance, and How Does Weever Drive Results? Discover the benefits of Autonomous Maintenance and how Weever drives efficiency with streamlined processes and real-time insights. Autonomous Maintenance (AM) is a great strategy for businesses striving to improve operational efficiency, reduce downtime, and empower their workforce. By giving operators the responsibility…

Read MoreAutonomous vs. Preventive Maintenance: Which Strategy is Best?

Autonomous vs. Preventive Maintenance: Which Strategy is Best? Compare the pros and cons of Autonomous vs. Preventive Maintenance and learn how Weever can help you choose the best strategy. Maintenance is a critical component of any successful manufacturing or industrial operation. Two prominent maintenance strategies-Autonomous Maintenance (AM) and Preventive Maintenance (PM)-offer distinct approaches to ensuring…

Read MoreWhat are the Key Differences Between Total Productive Maintenance and Autonomous Maintenance, and How Does Weever Support Both?

Discover the key differences between Total Productive Maintenance and Autonomous Maintenance, and how Weever supports both.

Read MoreWhat is the Comprehensive Guide to Clean Inspect Lubricate Tighten (CILT) for Autonomous Maintenance?

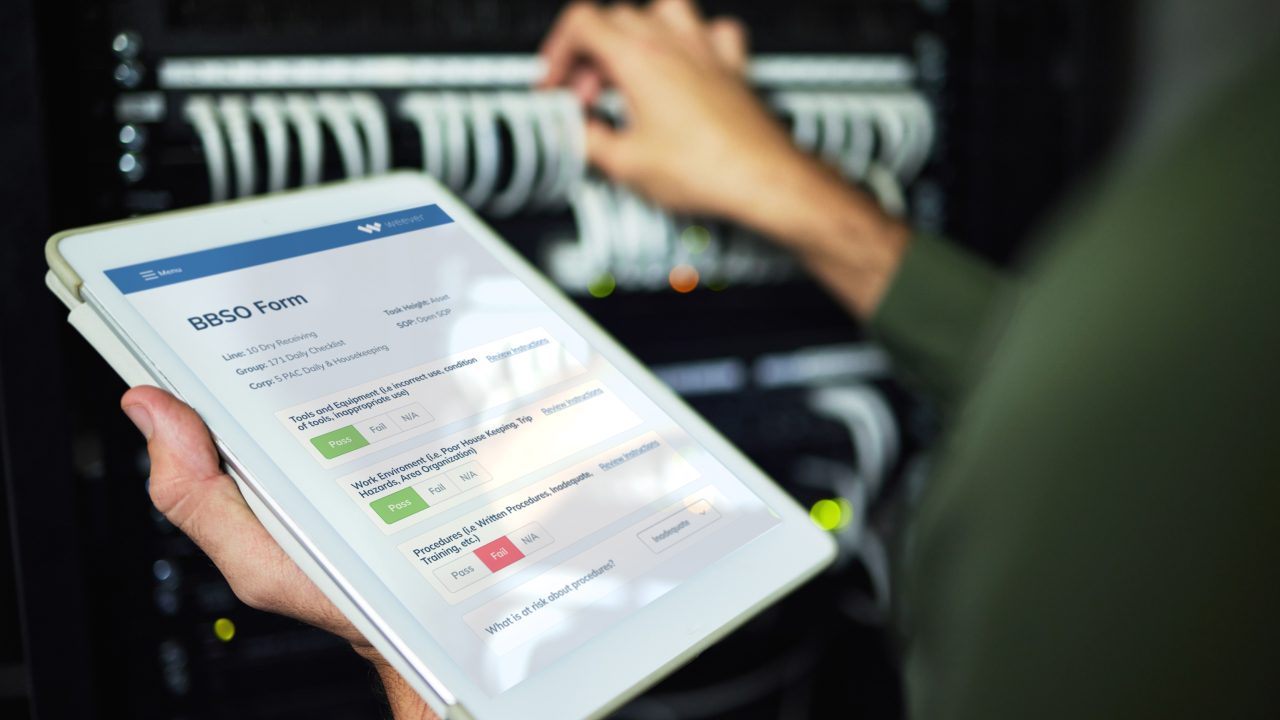

If you using paper forms, there are many benefits you can realize by switching to software, such as increased adoption, real-time escalation, on-demand instruction, rich data, and reducing the burden of administration.

Read MoreAutonomous Maintenance Benefits of Digitization

Complicated manual processes, data entry, messy paper forms or complicated spreadsheets can doom your new Autonomous Maintenance program to failure. Fortunately, Industry 4.0 and digitization provide us with many new tools to help make the implementation and execution of AM much easier.

Read MoreAutonomous Maintenance Best Practices

Here are some of the best practices and core challenges we’ve found helping massive global organizations, as well as regional manufacturers, to reap the benefits of Autonomous Maintenance over the last decade.

Read MoreHow Autonomous Maintenance Programs Work

Deciding that you’d like to implement Autonomous Maintenance in your plant is a great first step towards promoting a more efficient and profitable plant. Now you’re faced with the real challenge – how to begin?

Read MoreThe Benefits of Autonomous Maintenance

When properly implemented, AM can have a massive impact on the efficiency and profitability of a factory by reducing downtime, unplanned stoppages, while increasing OEE. The basic promise of AM is that it “outsources” simple maintenance tasks to operators which relieves maintenance teams to focus on more proactive concerns.

Read MoreWhat is Autonomous Maintenance?

Autonomous Maintenance, or AM, is part of the Total Productive Maintenance (TPM) school of Lean Manufacturing. It is one of the 8 TPM pillars which aims to increase the productivity of a plant in a sustainable way.

Read MoreWhat are the 7 steps of autonomous maintenance?

Quick overview of the 7 steps of Autonomous Maintenance from Increasing Operator Knowledge to Establishing Continuous Improvement and everything in between.

Read More