What are the 7 steps of autonomous maintenance?

Andy Pritchard | December 5, 2021 | 4 min read

What is Autonomous Maintenance?

Autonomous maintenance (AM) is an operations management practice that transfers the responsibility of basic maintenance tasks to machine operators so that technicians have more time to focus on more strategic and preventive maintenance deliverables. These basic maintenance tasks usually include machine and equipment cleaning, inspection and lubrication jobs.

Autonomous maintenance is a practice included in maintenance management methodologies like Total Productive Maintenance (TPM) and World Class Manufacturing (WCM). Autonomous maintenance empowers machine operators with the right training so they can independently identify quality issues and be able to take immediate action to correct them.

There are 7 steps involved in activating an Autonomous Maintenance program, which are designed to be incremental, so that you can slowly increase the skills and abilities of operators and ultimately arrive at truly autonomous maintenance.

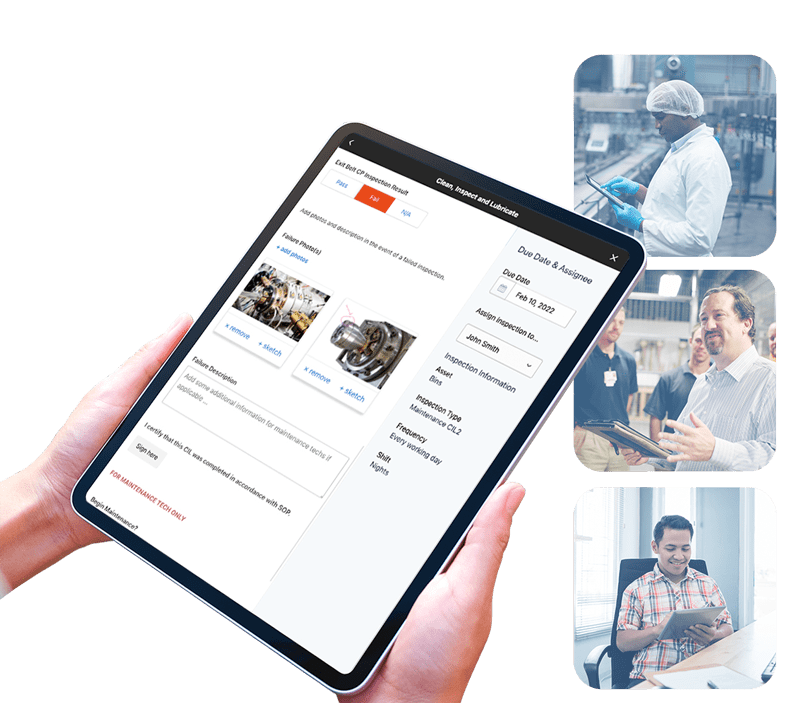

Using the Weever Platform will help to accelerate this process by providing real-time, interactive instructions, easy to follow “pass/fail” forms, automated maintenance ticket workflows, providing documentation and OPL (One Point Lessons) for SOP updates and, ultimately, maintaining a schedule for CILs.

What Are the Benefits of Autonomous Maintenance?

- Prevent issues from becoming major problems – Operators work closely and daily with machines and equipment. As a result, some simple training can provide them with the tools to recognize issues and take action quickly to prevent catastrophic problems.

- Free up maintenance personnel, so they can tend to more critical issues – They can plan and prioritize their specialized skills to higher-level and more complex equipment related issues.

- Improve team collaboration – Foster a more collaborative and less combative culture between production and maintenance staff.

- Improve Accountability – By making operators more accountable for the general performance of their machines and equipment, you increase accountability, which can have cascading effects on safety, quality, maintenance, continuous improvement and employee engagement.

- Verify equipment is properly cleaned and lubricated – When a maintenance technician is overseeing a big repair, simple tasks like cleaning and lubrication are often overlooked. But with autonomous maintenance, operators ensure these simple tasks are carried out.

- Lower labor costs – Reduce reliance on highly trained maintenance staff to do relatively simple cleaning, lubrication and inspection tasks.

Step 1: Increase Operator Knowledge

The first step in effectively implementing autonomous maintenance is to empower operators with the knowledge on how to operate and maintain the equipment that they’re assigned to use.

Equip them with knowledge on how the parts of the equipment come together so that they know which parts need periodic maintenance and which parts need to be looked after when it comes to cleaning, lubrication, etc.

Step 2: Initial Cleaning and Inspection

Once operators know the ins and outs of the equipment they are using, they should be able to inspect the equipment and spot any need for cleaning and maintenance. They need to be able to identify any part of the equipment that needs removal of dust and dirt, nuts and bolts that need tightening, oiling and lubrication, and wear and tear that needs fixing.

Step 3: Eliminate Causes of Contamination

Once the equipment is cleaned and back to its optimal working condition, the operator needs to know how to keep it that way. One way to keep the equipment in top condition is to eliminate causes of contamination. Maintaining good housekeeping and maintaining cleanliness at the workstation helps prevent contamination and keep the working environment safe.

Step 4: Set Standards for Lubrication and Inspection

Equipment should be cleaned, lubricated, and maintained according to manufacturer’s specifications in order to maintain its “like new” quality and level of performance. To set standards and reinforce those standards, tools and processes should be implemented on what maintenance tasks to do, how to do them, and how often they should be done.

Step 5: Conduct Inspection and Monitoring

To reinforce good practices like autonomous maintenance, it is recommended to conduct inspection and monitoring. Operators themselves can inspect their equipment and provide information in the form of inspection reports with photos on the current condition of the equipment and maintenance tasks fulfilled.

Step 6: Standardize Visual Maintenance Management

Make it easier for operators to complete maintenance tasks by implementing the use of visual cues such as color-coded tags and easy-to-understand signs or posters that remind operators and other workers of steps to follow when working with or being around equipment.

Create visual aids of the standards from step 4 to help operators follow and reinforce standards for maintaining equipment and machines.

Step 7: Establish Continuous Improvement

One of the pillars of TPM is improvement and as processes and equipment change, as well as the operators that handle equipment, there is good reason to establish continuous improvement for autonomous maintenance.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo