Sanitation Management

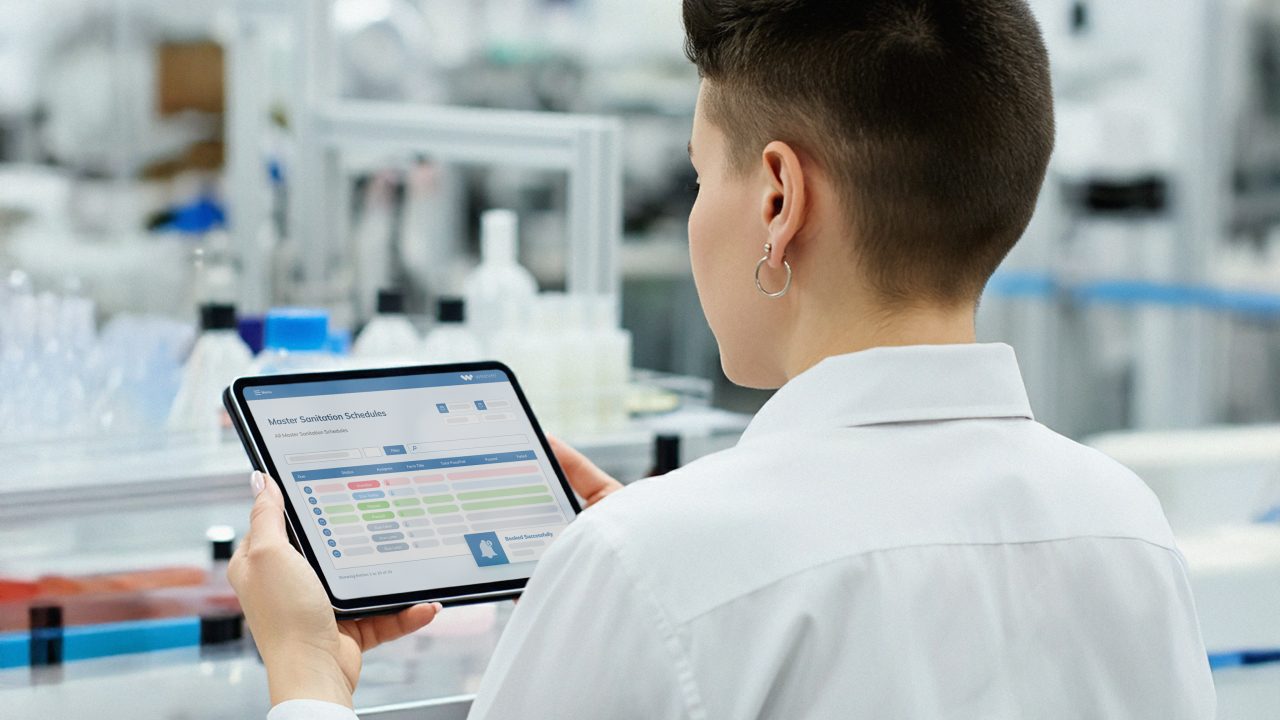

How Does Weever Software Support Configurable Master Sanitation Schedules for Food Manufacturing Plants?

How Does Weever Software Support Configurable Master Sanitation Schedules for Food Manufacturing Plants? Streamline food safety with Weever’s configurable MSS. Automate, customize, and optimize cleaning schedules for compliance, efficiency, and quality. Managing cleanliness and sanitation in food manufacturing plants is critical for maintaining food safety, ensuring compliance with industry regulations, and safeguarding product quality. A…

Read MoreWhat Are the Best Practices for a Master Sanitation Schedule, and How Does Weever Simplify Compliance for Manufacturers?

What Are the Best Practices for a Master Sanitation Schedule, and How Does Weever Simplify Compliance for Manufacturers? Streamline sanitation compliance with Weever’s MSS solution. Automate schedules, track cleaning tasks, and gain insights into food manufacturing safety and efficiency. A well-structured master sanitation schedule (MSS) is a cornerstone of effective sanitation management in food and…

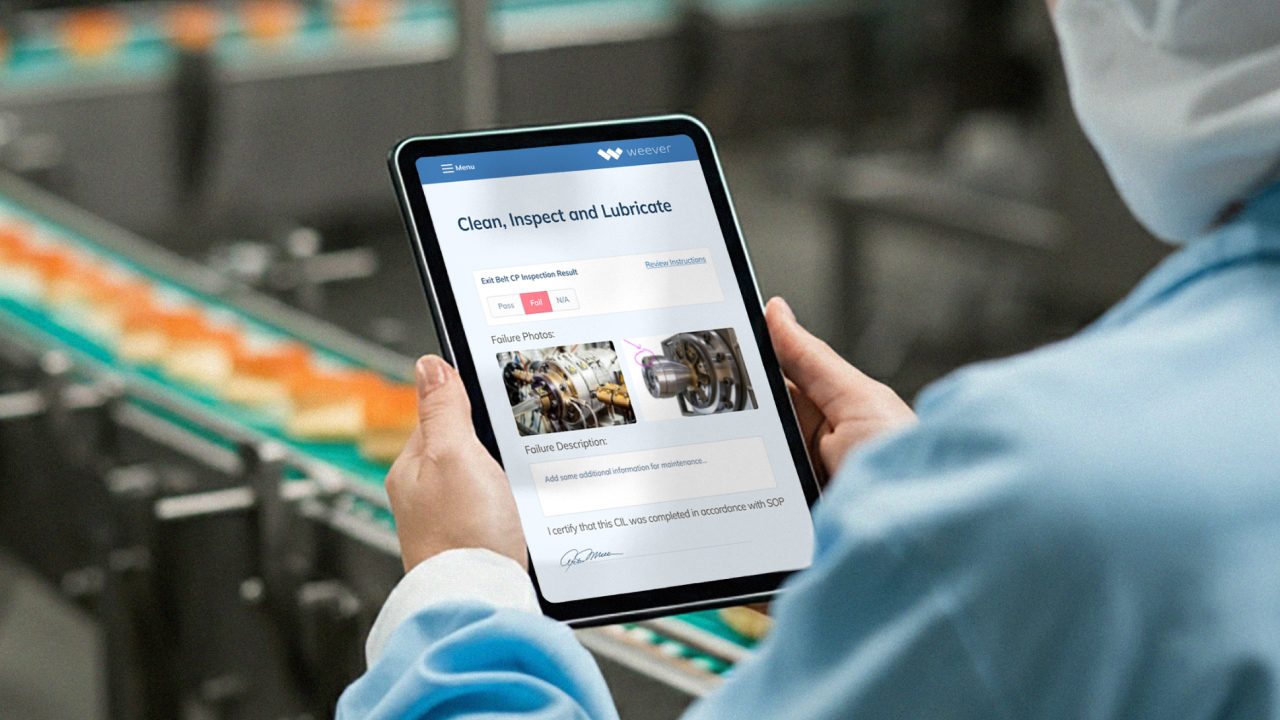

Read MoreHow Does Weever Software Streamline Planned Cleaning in Food Production?

How Does Weever Software Streamline Planned Cleaning in Food Production? Streamline sanitation in food production with Weever. Automate cleaning schedules, track performance, and ensure compliance with real-time insights. In the food production and related industries, maintaining cleanliness is a non-negotiable priority. Effective sanitation ensures compliance with regulatory requirements, safeguards product quality, and upholds consumer trust.…

Read MoreHow Does Weever Software Simplify Tracking the Frequency of Cleaning in Manufacturing Plants?

How Does Weever Software Simplify Tracking the Frequency of Cleaning in Manufacturing Plants? Streamline cleaning schedules with Weever. Automate tasks, track cleaning frequency, and gain insights to enhance compliance and efficiency in manufacturing. Maintaining cleanliness and sanitation is more than a regulatory requirement-it’s a critical factor for ensuring product quality, operational efficiency, and food safety.…

Read MoreWhy Weever Software is the Optimal Tool for Your Master Sanitation Program

Why Weever Software is the Optimal Tool for Your Master Sanitation Program Discover why Weever is the top choice for implementing a Master Sanitation Program in manufacturing. Ensuring top-notch cleanliness and compliance in the food manufacturing sector requires a robust Master Sanitation Schedule (MSS). The complexity of managing scheduled cleanings and equipment maintenance in such…

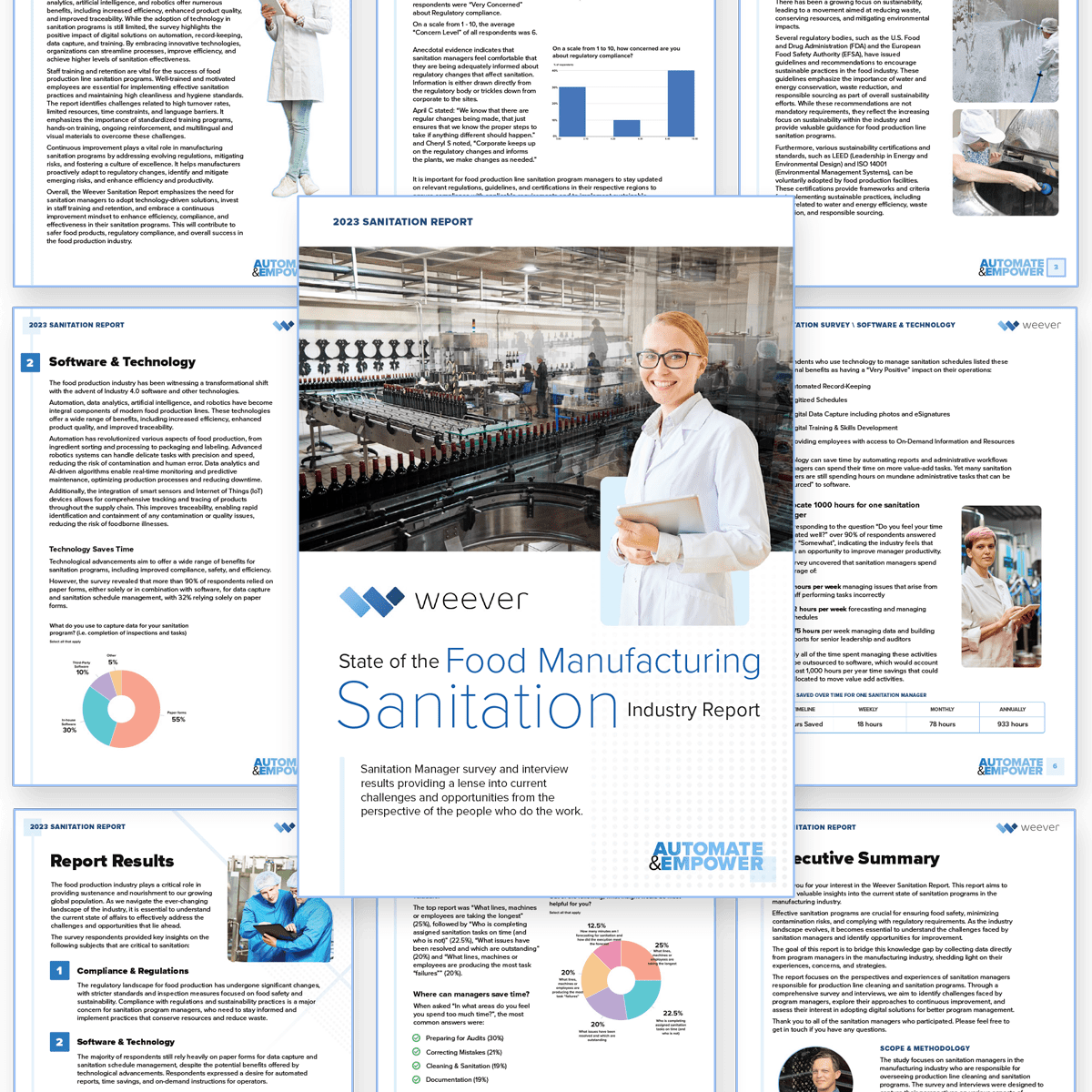

Read MoreState of the Food Manufacturing Sanitation Industry Report

Learn more about the food production line sanitation industry from the people who manage the work, including challenges and opportunities, training and retention, regulations, software and technology, and continuous improvement.

Read MoreTop 5 Benefits of digitizing food plant sanitation schedules

There are many advantages to digitizing your sanitation schedule, including improved efficiency, increased accuracy and consistency, improved compliance, reduced costs and risks and improved data management.

Read MoreThe 7 Steps of Cleaning & Sanitizing food production lines

Regulatory bodies and food safety programs worldwide have their own slightly varied versions for properly cleaning and sanitizing food contact surfaces and equipment. However, this list, provided by the NSF overviews the most commonly suggested steps among the different renditions.

Read MoreHow software will optimize your sanitation program

Over the past 10 years, Weever has been on the front lines of helping global Fortune 100 manufacturing companies implement and maintain successful 5S programs. We’ve learned a lot from our clientele over the years and we’re happy to share those lessons here.

Read MoreTop 10 best practices of Sanitation in Food Processing

Over the past 10 years, Weever has been on the front lines of helping global Fortune 100 manufacturing companies implement and maintain successful 5S programs. We’ve learned a lot from our clientele over the years and we’re happy to share those lessons here.

Read More