Autonomous Maintenance Digitization Benefits

Andy Pritchard | July 19, 2022 | 5 min read

Rolling out a new Autonomous Maintenance program is a wise investment to help make your plant more efficient, reduce downtime, and free up your technicians for more high value work. However, it is an investment of valuable time and resources that takes your staff away from what makes your business successful.

Complicated manual processes, data entry, messy paper forms or confusing spreadsheets can doom your new Autonomous Maintenance program to failure. Fortunately, Industry 4.0 and digitization provide us with many new tools to help make the implementation and execution of AM much easier.

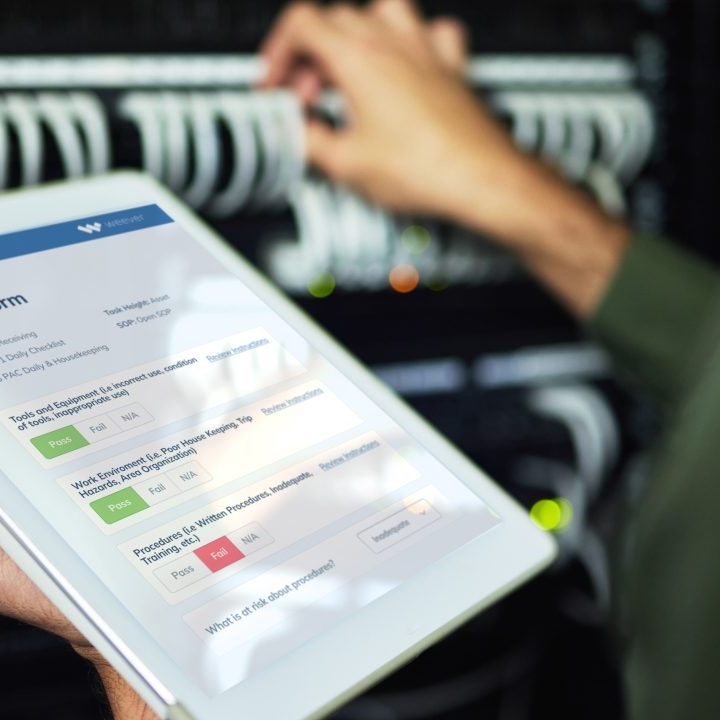

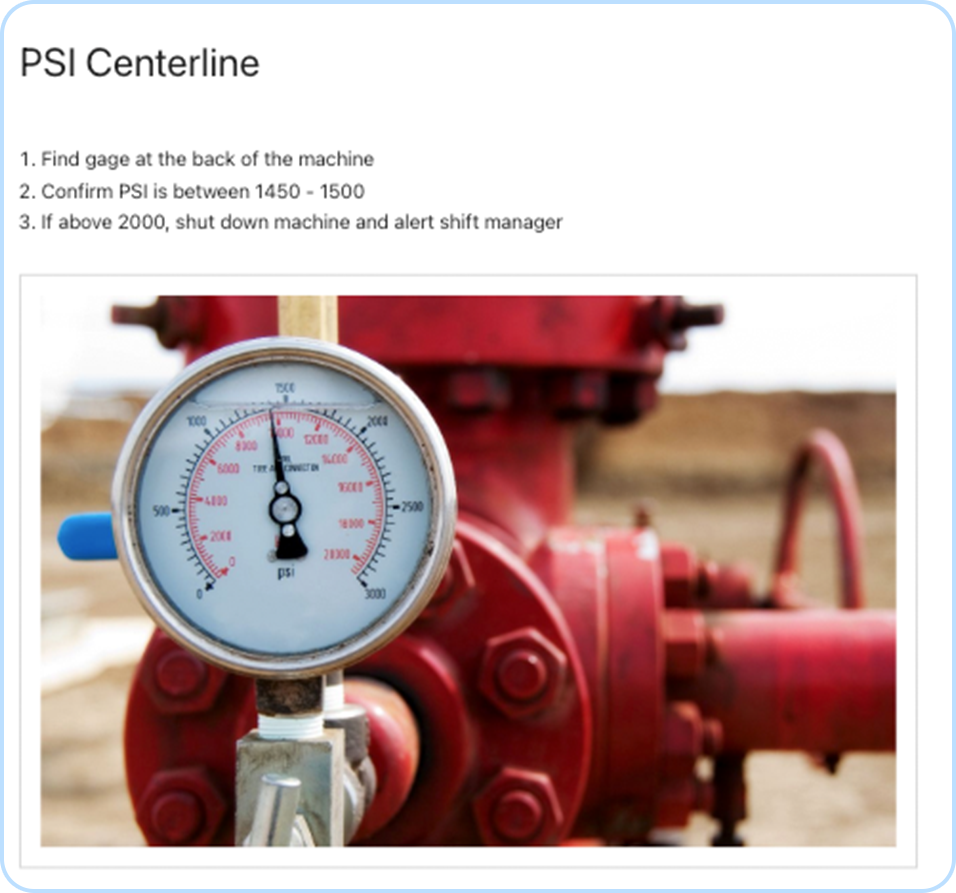

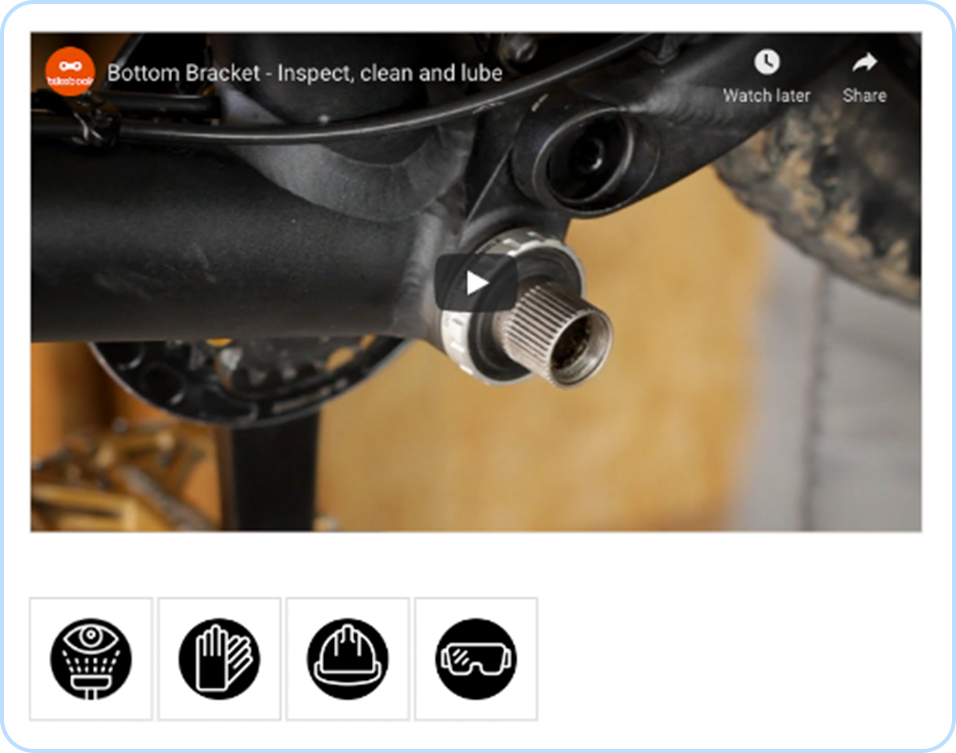

on-demand instruction

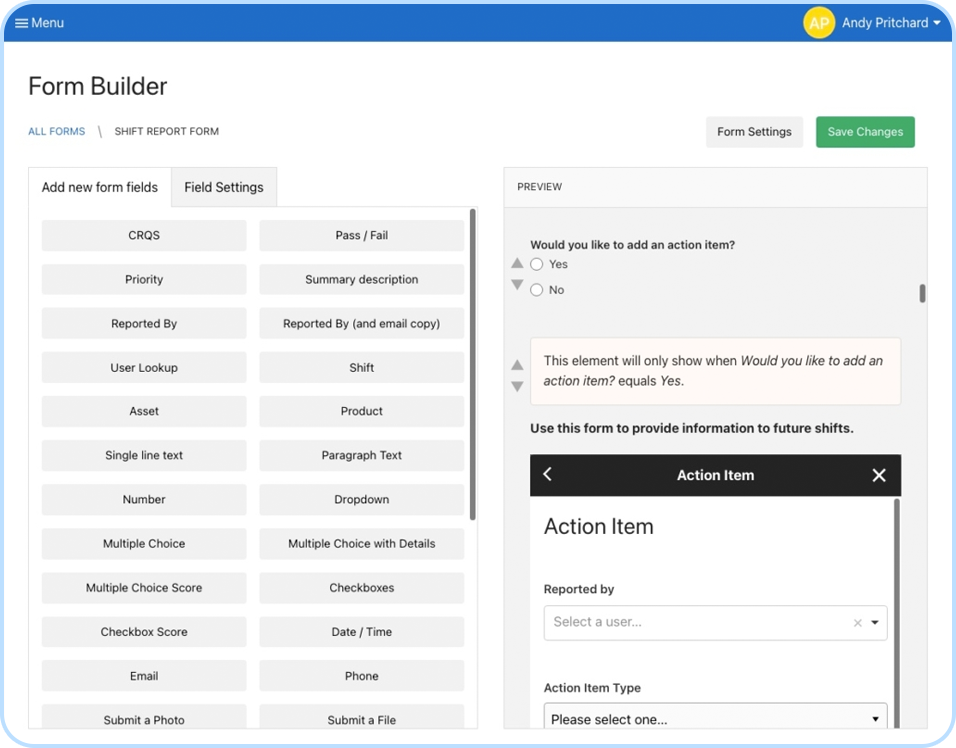

Show them the way

Give your operators a tablet or workstation with a step-by-step guide on how to complete their inspections and centerlines to reduce training requirements when there is staff turnover. Multiple choice, dropdown menus, and conditional logic help you capture the data you need in a logical and easy-to-follow format. Forms are customizable and simple to change so they can evolve as your Autonomous Maintenance requirements do.

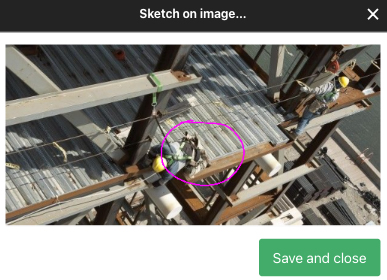

more data in less time

Get Richer Data

A picture is worth a thousand words. Take a photo with your phone or tablet that automatically populates in your inspection or audit forms. Photos are especially helpful in evaluating deterioration over time. Talk-to-text allows your staff to say what they mean and capture it without the hassle of typing long or complex observations.

efficiency & consistency

Leverage Templates

Prebuilt and customizable audit and inspection templates make floorwalks easy. Track scores digitally and let the software do the tallying for you. Results flow automatically into detailed dashboards that let you track how your teams are doing without any tedious or time-consuming data entry.

motivate & inspire

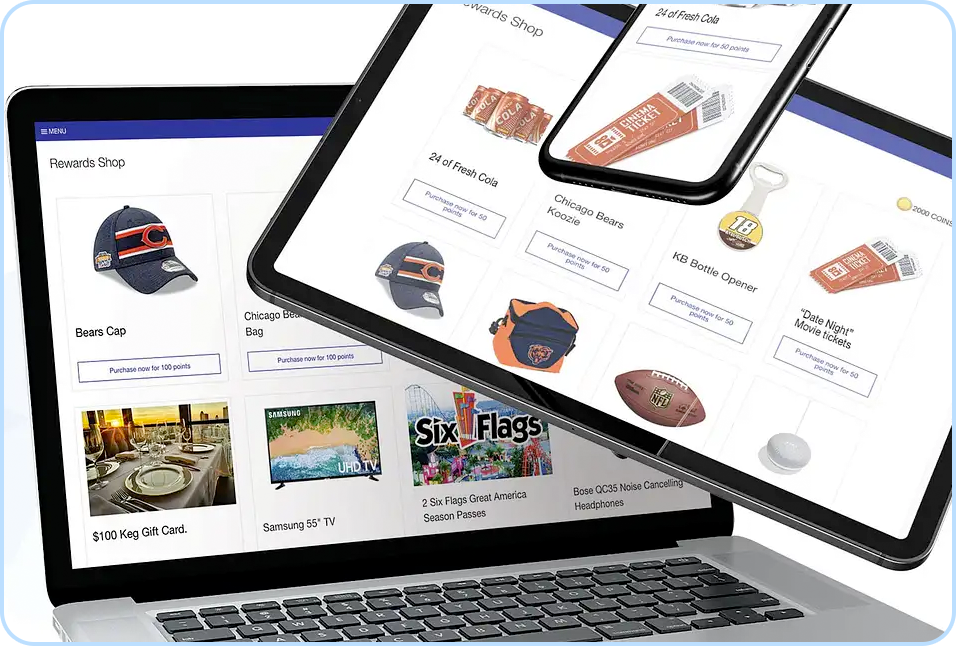

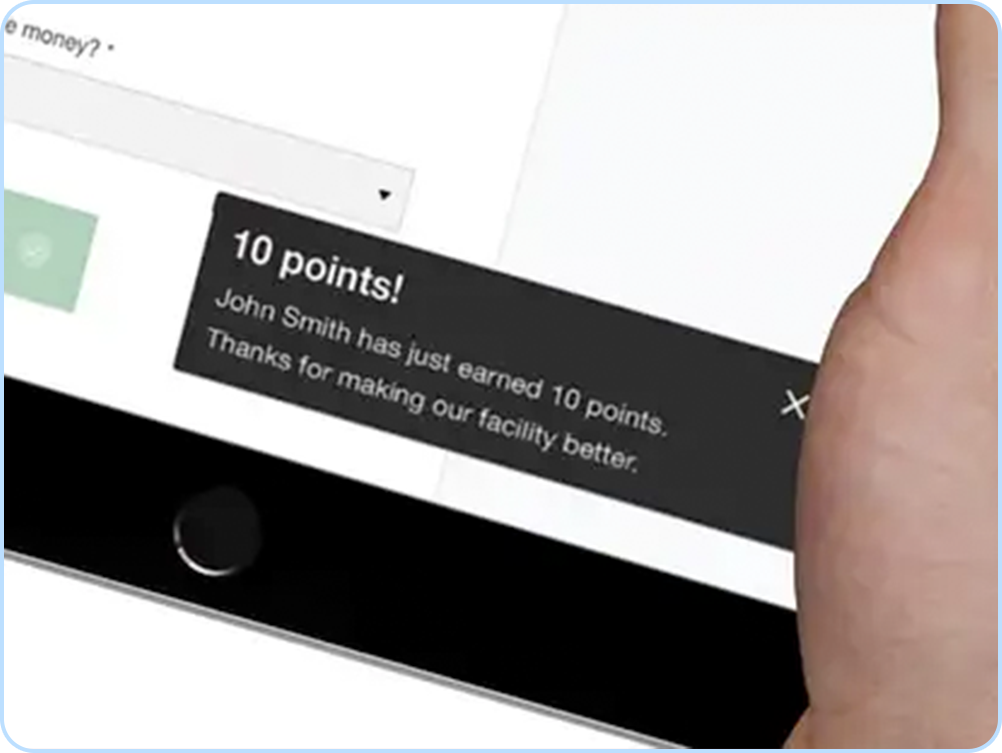

Reward Participation

Weever Rewards allows you to automatically reward your AM champions with points that can be redeemed in a self-managed rewards store. Broadcast the results of your top operators in your plant. Everybody likes seeing their name “up in lights”!

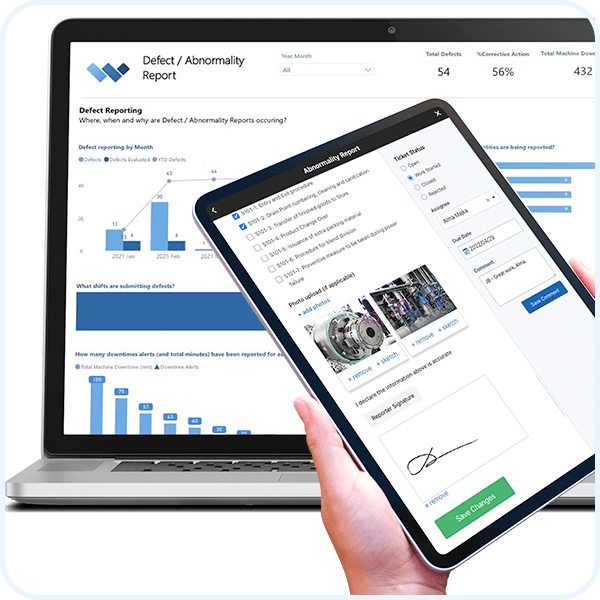

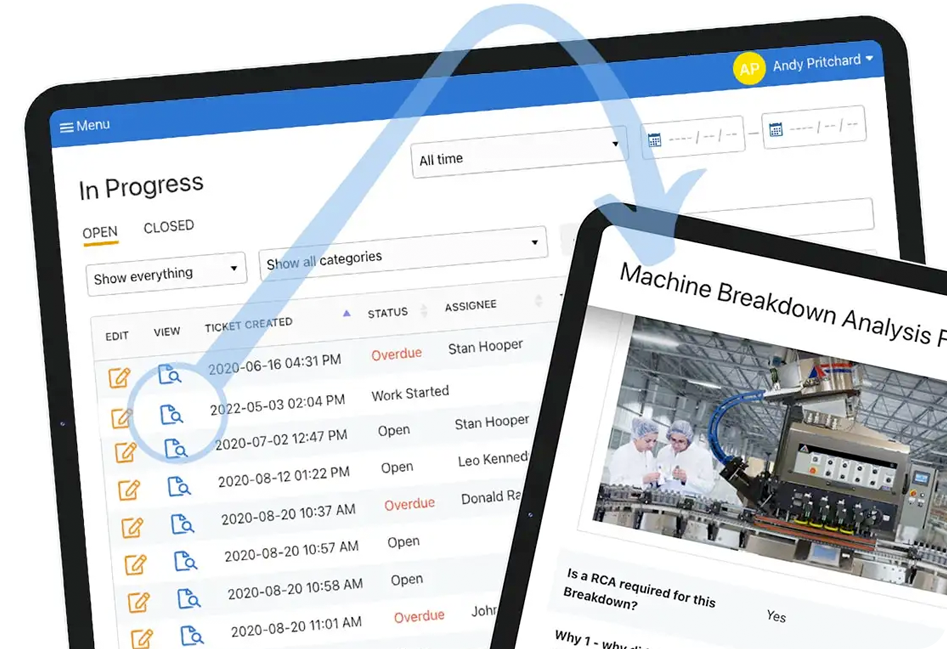

automate workflows

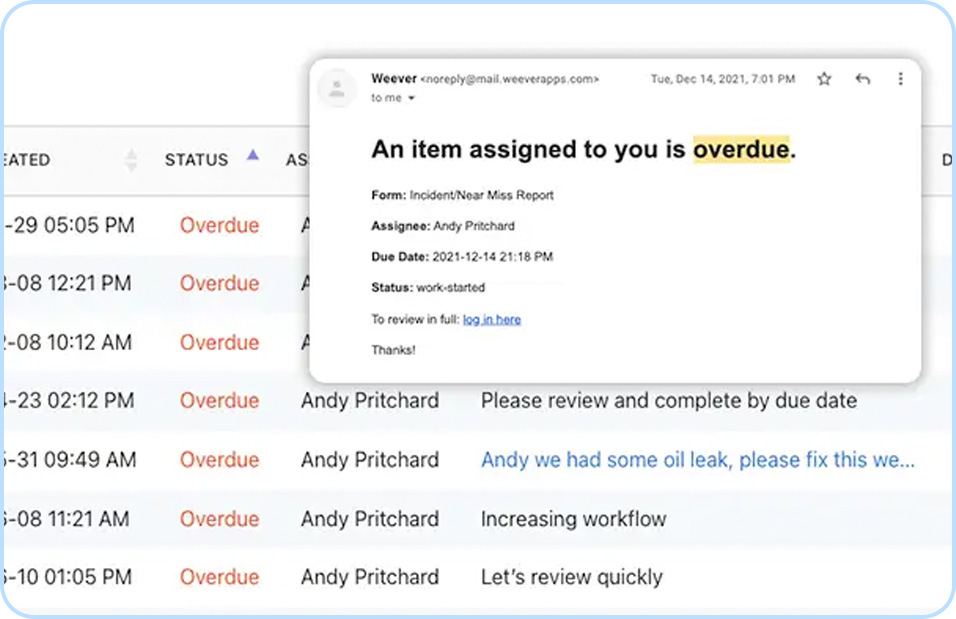

Tickets Please

Automatically transform CILS, centerlines, failed inspections, and audits into tickets. Foster easy and transparent communication between operators and technicians to ensure maintenance items are actioned in a timely manner. Email notifications to stakeholders let them know when they’re needed. Track closing times to ensure world-class support.

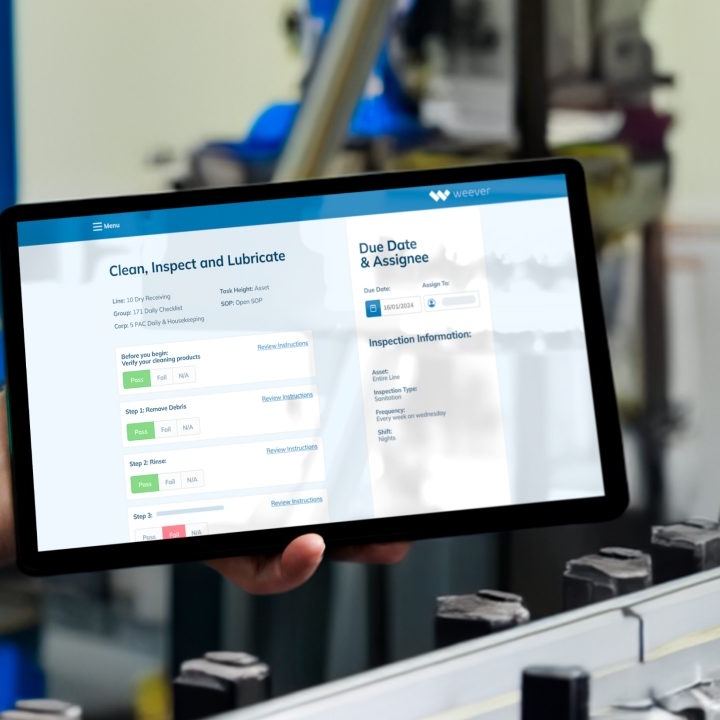

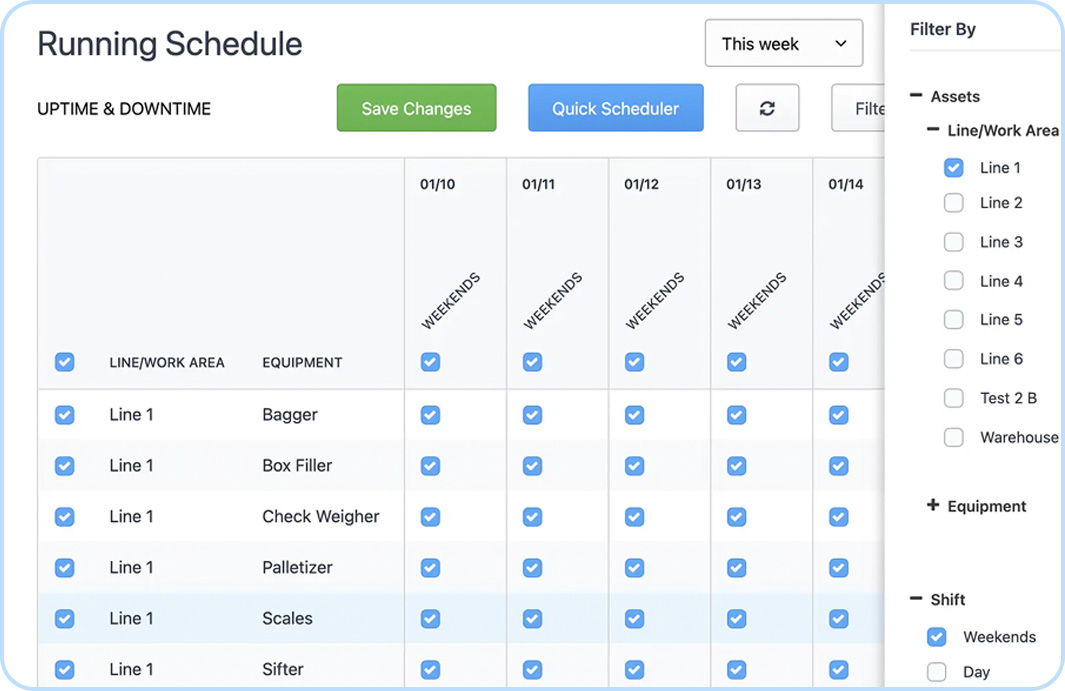

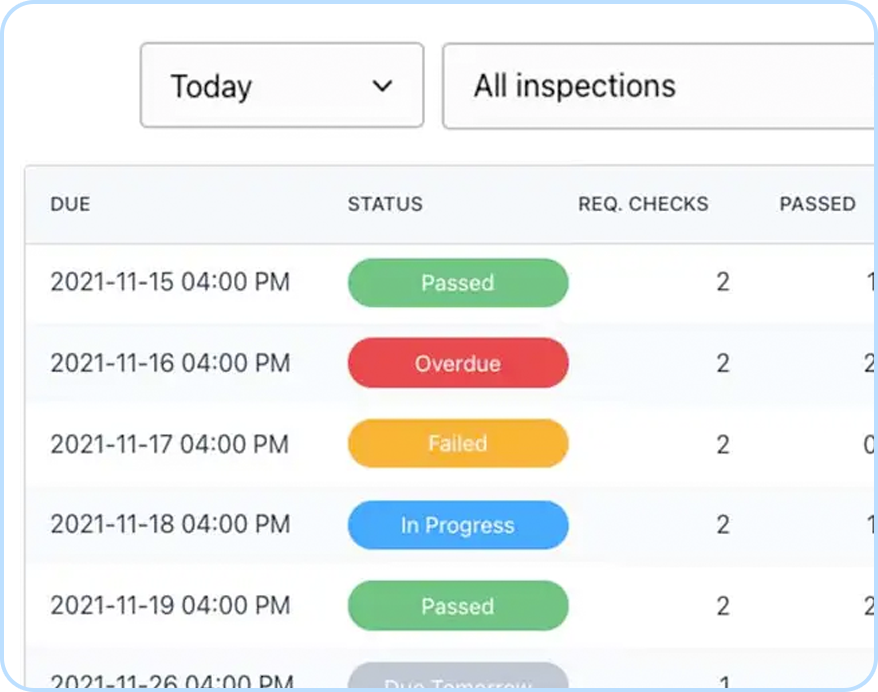

automate schedules

The Right Frequency

Schedules can be built and tracked so important maintenance items are completed when they need to be. Operators and Technicians can easily see which inspections are up next. Plan your Autonomous or Proactive Maintenance activities on a daily, weekly, monthly, or annual basis. Need to change the schedule for a holiday, maintenance, or any other reason? No problem - just select the date and uncheck the inspections. How many inspections were missed? Overdue items are color-coded in your maintenance schedule or just set up email notifications to remind you when they’re due.

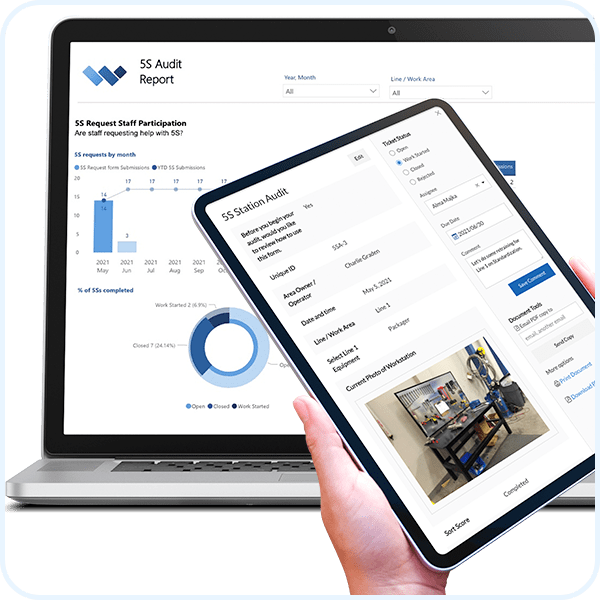

real-time reporting

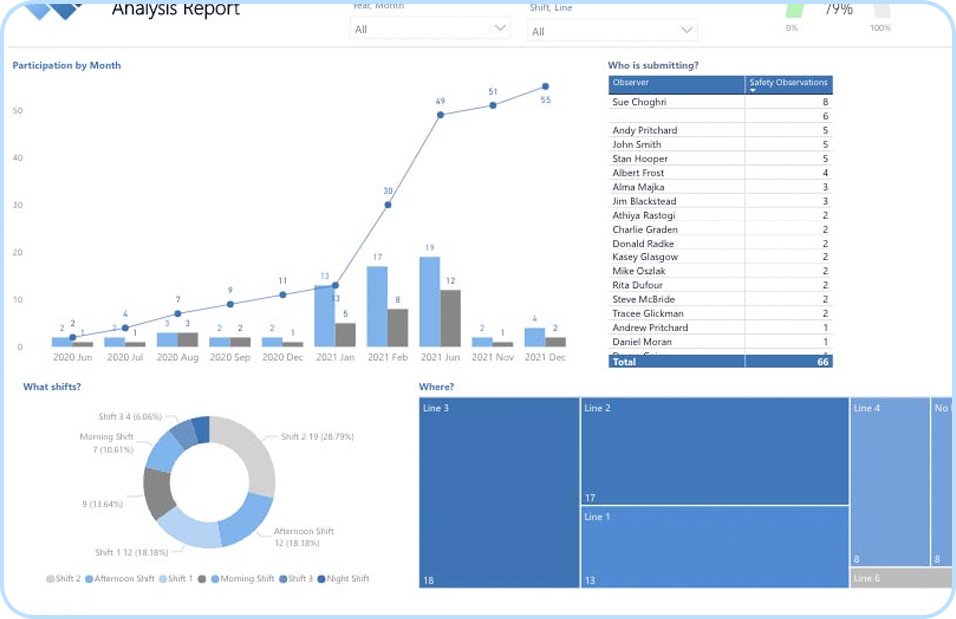

Insightful Dashboards

Weever automatically populates rich and interactive dashboards that will allow you to see inspection and centerline insights in real time. Managers can save up to 30% of their day that used to be spent administering spreadsheets by automating reporting. Review and share KPIs on the entire plant or a single machine. Understand insights at-a-glance that inform better predictive maintenance measures. Plan your next set of One Point Lessons based on real data.

Download the Ultimate Guide

Everything you need to know about how Autonomous Maintenance works and the best practices gleaned from our 10+ years of experience helping organizations achieve success.

Continue Reading about Autonomous Maintenance

Ultimate Guide to Success with Autonomous Maintenance

Everything you need to know about how Autonomous Maintenance works and the best practices gleaned from our 10+ years of experience helping organizations achieve success.

Everything you need to know about how Autonomous Maintenance works and the best practices gleaned from our 10+ years of experience helping organizations achieve success.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo