What is Food & Beverage Production Line Sanitation?

Andy Pritchard | January 19, 2023 | 5 min read

Cleaning and sanitation programs are the backbone of creating a safe plant environment for employees and for the food it produces.

Food processing and packaging equipment accumulate grease, carbonized residue, seasonings, proteins, harmful bacteria, biofilms, adhesives, labels, and many other contaminants that traditionally take significant time to clean.

Definitions

CLEANING: The removal of soil particles from surfaces by mechanical, manual or chemical methods.

SANITIZING: Treatment of a cleaned surface with a chemical or physical agent to destroy disease/spoilage causing organisms. Reduces total vegetative cell population to a safe level.

DISINFECTING: Destruction of all vegetative state organisms.

STERILIZING: The complete destruction of all organisms, including spores.

Although similar in nature, cleaning and sanitizing are different procedures with different goals.

Cleaning helps increase the effectiveness of sanitation efforts by removing organic materials such as dirt, soil, and debris at a visible surface level. This organic matter can be a breeding ground for bacteria. Therefore, cleaning needs to always be done first.

Sanitizing is what actually reduces the number of bacteria and other microorganisms to levels considered safe for human health.

While cleaning is an everyday activity and can be automated using machines, line sanitation is relatively infrequent and usually very manual.

If sanitation is conducted incompletely or incorrectly, the consequences can be devastating for the business, the brand, and the customers. On the other hand, when sanitation is conducted correctly, the result is an increase in food safety and quality, increased production uptime, and, potentially, more sales.

Types of Cleaning & Sanitation

There are many different ways to clean and sanitize equipment. These include the use of clean-in-place (CIP) systems, foaming, clean-out-of-place (COP), spraying, high-pressure, and manual systems. Manual is the old-fashioned route that usually involved scrubbing of some sort. But no matter which kind of cleaning and sanitizing is selected, there are basic issues that must be considered.

Cleaning in place (CIP)

A set of activities conducted to properly clean all or part of a process system as it sits in place, without removing or disassembling piping or equipment to accommodate the cleaning. Processors should work closely with their chemical supplier to develop the proper CIP sequencing for their CIP cleaning.

Clean out of Place (COP)

A cleaning/sanitation system where equipment is disassembled for cleaning and inspection.

Foam Cleaning

Foam cleaning is a form of soft washing that uses low-pressure foam to clean surfaces. The foam clings to the dirt and debris, allowing it to be removed without using harsh chemicals or pressure washers. This makes foam cleaning a safe and gentle alternative to other forms of cleaning.

Spraying

Spray technology is an effective method for applying antimicrobial agents, mold inhibitors, sanitizers, and chemicals.

High-Pressure

High-pressure water cleaning is the use of high-pressure water between 5,000 to 10,000 psi (34 to 70 MPa) to remove grime, loose paint, mud, mold, dust, and other types of stubborn dirt on the surfaces of tanks, buildings, vehicles, streets, bridges, pipes, and many more items.

Manual

Employees physically clean equipment by removing dirt, grease and scraps, rinsing, cleaning, sanitizing, and air drying.

How-to instructions, best practices, and customer stories to help you set up and optimize your cleaning and sanitation program.

How-to instructions, best practices, and customer stories to help you set up and optimize your cleaning and sanitation program.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

Learn more about Sanitation ...

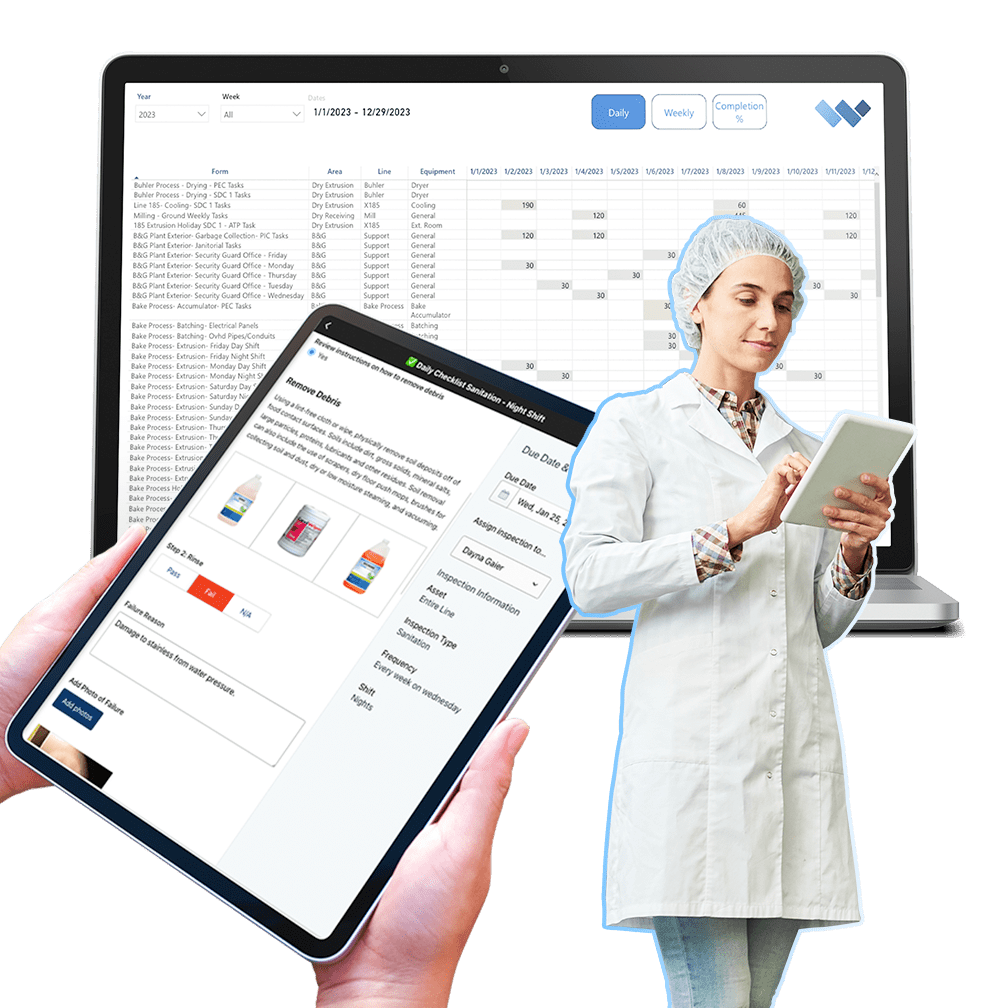

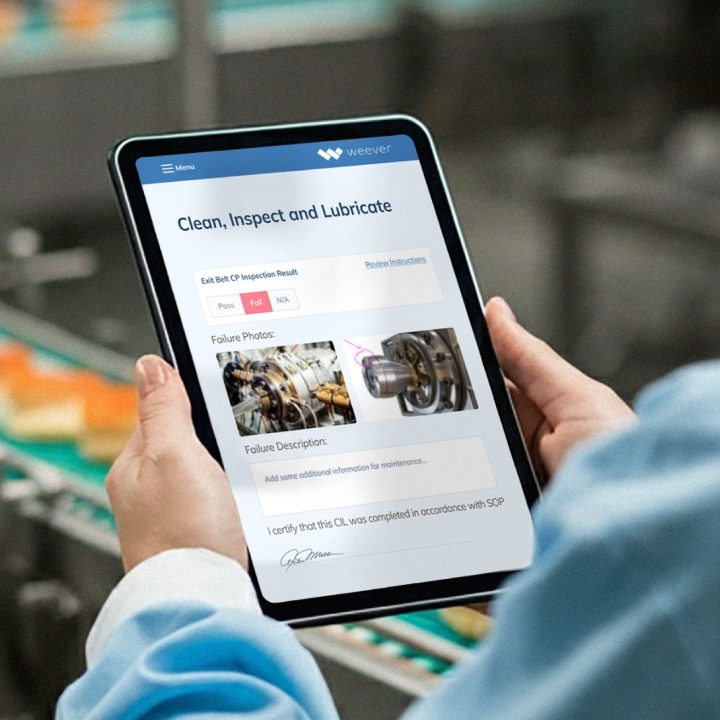

Weever is a comprehensive operations management platform that is used to automate safety, quality, maintenance, production, compliance, continuous improvement and training operational requirements.