operational excellence

The Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency

The Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency Enhance manufacturing with predictive maintenance. Learn how Weever’s software integrates data collection and analysis to not only prevent, but predict equipment failures. Predictive maintenance is a game-changer in the manufacturing industry. Unlike traditional reactive maintenance, which fixes problems after they occur, predictive maintenance anticipates issues…

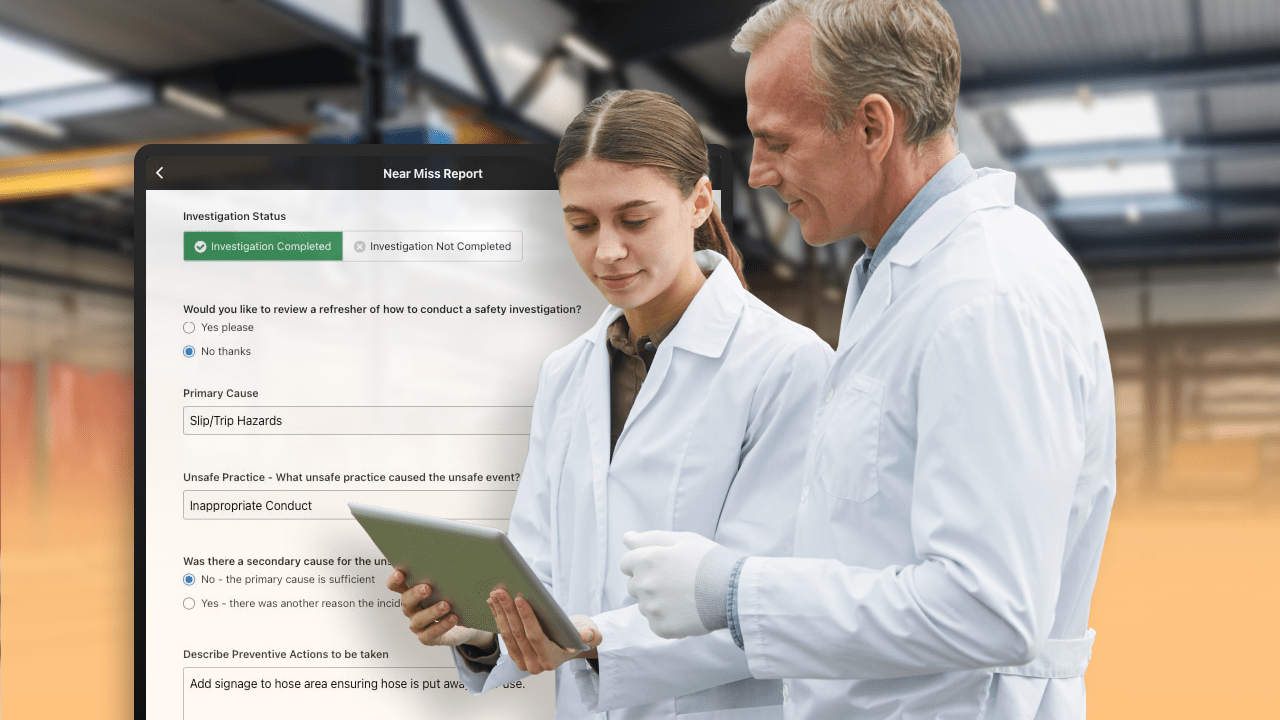

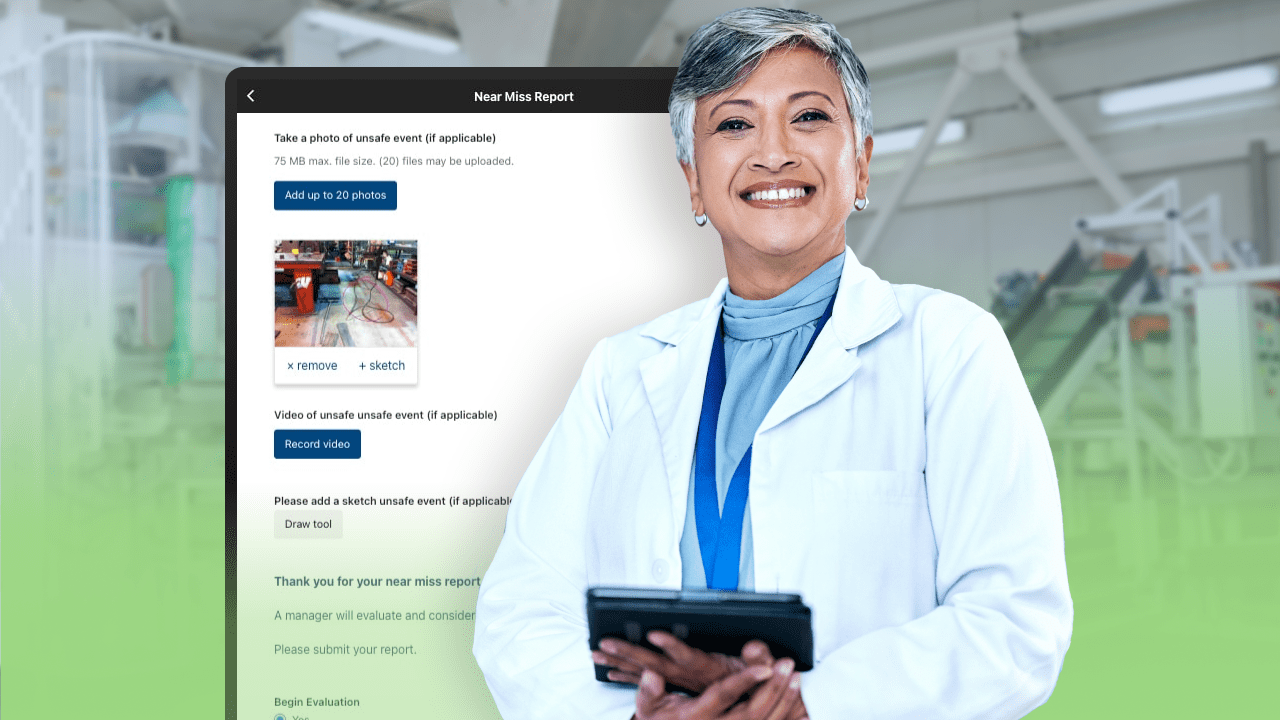

Read MoreHow Near Miss Reporting Software Can Transform Your Manufacturing Safety Culture

How Near Miss Reporting Software Can Transform Your Manufacturing Safety Culture Discover how Weever’s Near Miss Reporting software transforms manufacturing safety with digital data capture, automated tasks, and real-time insights for a proactive safety culture. Safety in manufacturing is crucial for protecting employees and maintaining efficient operations. Weever’s Near Miss Reporting software helps identify and…

Read MoreTop Features in Near Miss Reporting Software for Manufacturing

Top Features in Near Miss Reporting Software for Manufacturing Discover top features in near miss reporting software for manufacturing. Learn how Weever’s solutions improve safety, streamline reporting, and boost efficiency. In manufacturing, near miss reporting software is crucial for preventing accidents and enhancing safety. By capturing and analyzing incidents that almost led to accidents, manufacturers…

Read MoreHow a Configurable Program Template Can Transform Your Manufacturing Operations

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Read MoreTop 5 Benefits of Paperless Factory Operations

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. Schedule a Free Demo Today! This article reviews the following topics: Real-Time Visibility Cost Savings Employee Engagement Simplicity & Structure Compliance If you are reading this you have probably hit a…

Read MoreHow to effectively manage end-of-shift reports in manufacturing

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: What are end-of-shift reports and why are they valuable? Broadcast Updates Capture Data with Mobile Devices Report the Essentials and Avoid Clutter What are end-of-shift…

Read MoreWhy digitize factory operations?

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: Cost Savings Real-time Visibility Automation Simplicity & Structure Compliance There are countless benefits to transitioning paper and spreadsheet-based processes to a digital framework. Paper has…

Read MoreThe Problem with Paper

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: Stagnant Waste Time Errors Inconsistent Why do paper forms limit factory operations and continuous improvement? Manufacturers come in a lot of different shapes and sizes.…

Read MoreConditional Number Fields – Use Cases & Best Practices

The Weever platform includes conditional number functionality. This allows administrators to reveal certain form fields only if a response to a number field is above, below or in between a given threshold. This article reviews some applicable use cases and best practices for how to set this up in your forms. Use Cases Cycle of…

Read MoreOut-of-tolerance checks best practice – conditional number fields

Autonomous Maintenance Inspections Autonomous Maintenance, a focus for many of our customers, requires machine operators to take on simple maintenance tasks (like cleaning, inspecting and lubricating components). This frees up time for the maintenance team, allowing them to focus on predictive and/or preventive measures. With conditional numbers, it is possible to provide additional required inputs…

Read More