How to execute the 5S Set in Order Step

Practical guide for enhancing workstation orderliness to increase productivity, efficiency and employee engagement.

5S Overview

5S Planning

5S Implementation

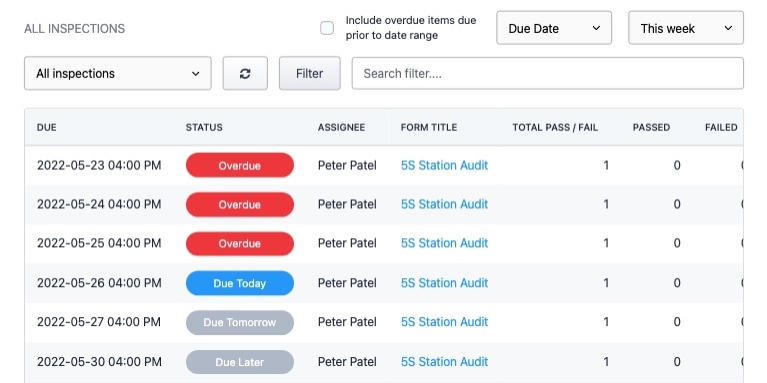

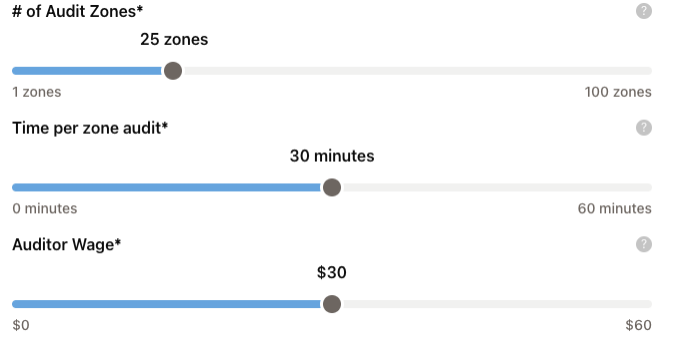

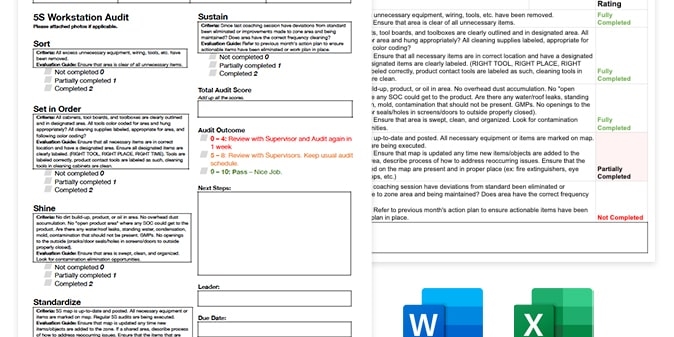

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Set in Order focuses on arranging essential items in a logical and efficient manner, optimizing the workspace layout for improved accessibility, safety, and workflow.

This step ensures that everything has its designated place, streamlining processes and reducing waste.

We recommend using the “Optimization Blitz” approach to 5S implementation, where you work with small teams and execute each of the first 3 steps one per day. This approach allows for you to get the best results in the shortest amount of time.

But before we get into the Set in Order step, let’s review the 5S methodology and the first “Sort” step that will need to be completed before you begin to set workstations in order.

What is 5S and how does it work?

The 5S methodology is a systematic approach aimed at organizing a workspace for efficiency and effectiveness. It consists of five steps, each starting with the letter "S":

- Sort: Eliminate unnecessary items from the workspace, keeping only the essentials.

- Set in Order: Organize and arrange necessary items in a logical and accessible manner for easy retrieval and use.

- Shine: Clean the workspace regularly to maintain cleanliness and identify any issues or abnormalities.

- Standardize: Establish and maintain standardized work procedures to sustain the improvements made in the first three steps.

- Sustain: Develop a habit of maintaining the established standards and continuously improving the workspace.

The Sort step aims to declutter workspaces by identifying and removing unnecessary items. It's about distinguishing between what's needed (the essentials) and what's not (the clutter). By reducing unnecessary items, teams create streamlined, organized, and efficient work areas, laying the groundwork for improved productivity.

When you have completed sorting, the next step is to Set the workstation in Order.

The Set in Order Step

The Set in Order is the “magical” step in the 5S process and it can be viewed as more of an art than a science. As a result, you may want to consider hiring the services of a lean practitioner to help you execute this crucial step.

Here is a detailed overview of the steps involved.

How to Set in Order a Workstation

The Set in Order step within the Optimization Blitz is pivotal in reorganizing workspaces for enhanced efficiency and safety.

By collaboratively assessing, redesigning, and implementing optimized layouts, frontline staff and 5S leaders create a more organized and streamlined workspace, facilitating smoother operations and improving overall productivity.

This sets the stage for the subsequent steps in the 5S methodology, emphasizing sustained orderliness and optimization within the manufacturing environment.

1. Evaluate Current Layout

Begin by evaluating the current layout and organization of the workspace. Assess how items are currently arranged and identify any inefficiencies or safety hazards.

2. Determine Optimal Layout

Collaborate with frontline staff to determine an optimal layout. Consider factors like workflow patterns, frequency of item use, ergonomic considerations, and safety protocols.

3. Establish Item Placement Guidelines

Develop clear guidelines for item placement based on their frequency of use, workflow sequence, and ergonomic considerations. Designate specific areas for different categories of items.

What to Consider and Look For:

- Accessibility: Ensure items are easily reachable and accessible, reducing unnecessary movement or bending.

- Safety Measures: Arrange items to minimize safety hazards, keeping heavy or hazardous items stored securely and appropriately.

- Optimal Space Utilization: Maximize space utilization by organizing items efficiently, avoiding clutter and obstructions.

4. Redesign Workspace Layout

Based on the determined guidelines, rearrange the workspace layout. Ensure commonly used items are easily accessible, frequently accessed tools are within arm's reach, and less used items are stored further away.

Interested in learning more about Weever?

Best Practices for Setting in Order

For best results during the Set in Order process encourage team collaboration, use clear labelling and set yourself up for continuous improvement. Here are some best practices for the Set in Order stage:

Team Collaboration

Engage frontline staff in decision-making for layout redesign, considering their insights and preferences.

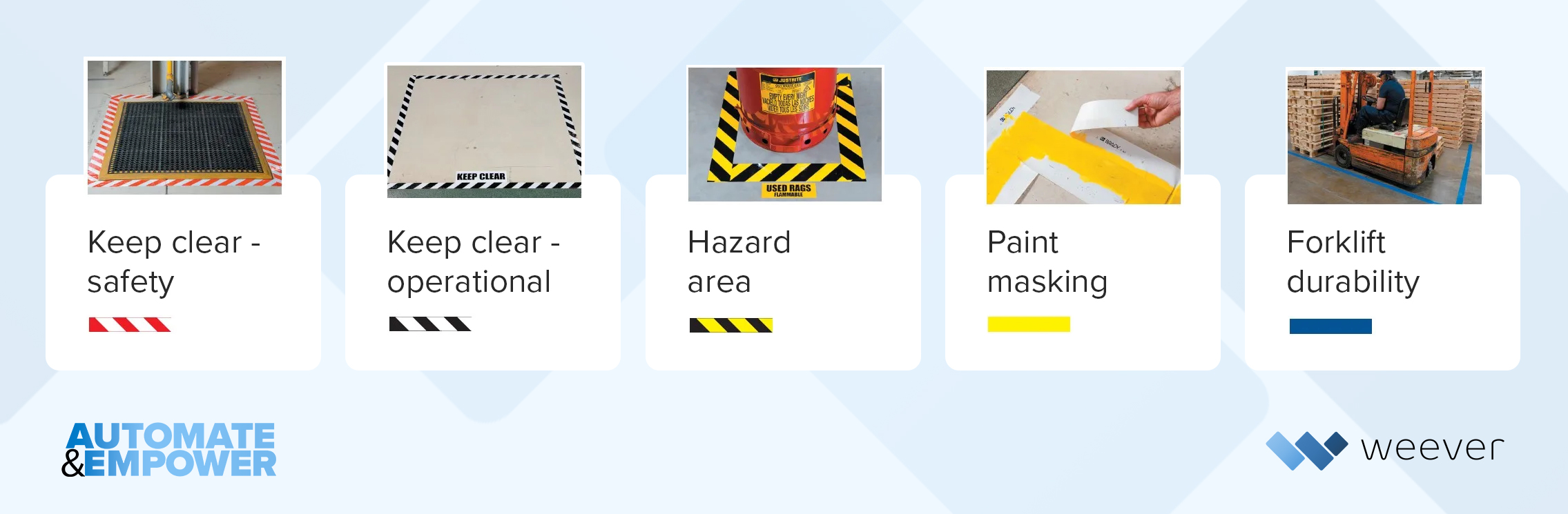

Labeling and Signage

Use clear and standardized labeling and signage for item placement to facilitate easy identification.

Periodic Reviews

Conduct regular reviews of the workspace layout to ensure it aligns with operational needs and make adjustments as required.

Continuous Improvement

Foster a culture of continuous improvement, encouraging feedback and suggestions for further workspace optimization.

Documentation

Keep records of the decisions you made during the Set in Order step. It is helpful to include before and after photos for each section in the workstation. These can be used to build Standardization SOPs and Audit checklists later in the 5S process.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo