How to Conduct Successful 5S Audits

Step-by-step guide to conducting 5S audits to foster continual improvement and reinforce the principles of organization and efficiency.

5S Overview

5S Planning

5S Implementation

5S Auditing

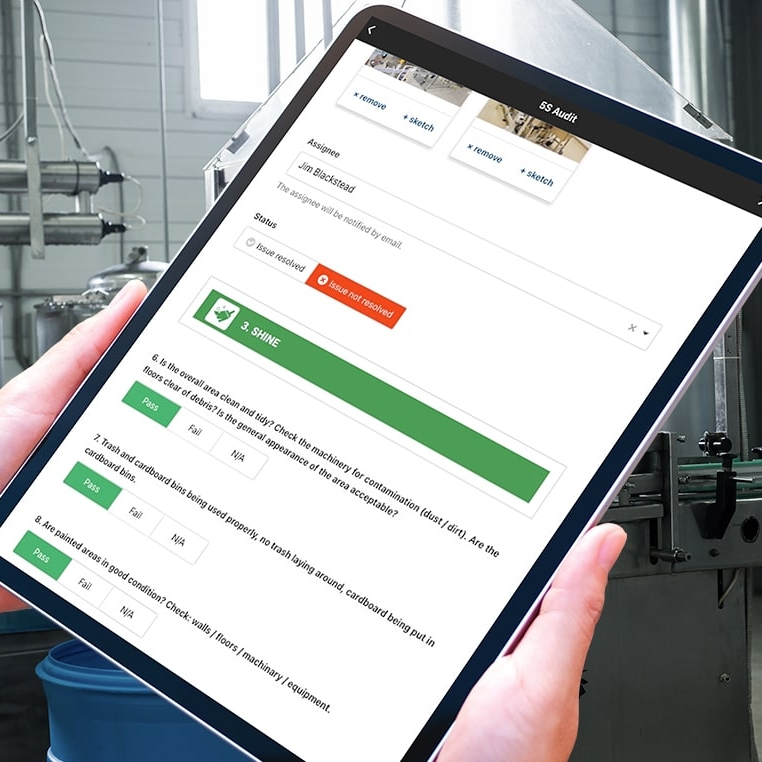

5S Audit Digitization

FREE RESOURCEs

In the quest for operational efficiency and workplace optimization, the 5S methodology stands as a cornerstone. At the heart of 5S lies the practice of auditing—an instrumental process ensuring adherence to its principles. Let’s explore the essence of 5S auditing and unveil the essential steps to conduct audits that drive continuous improvement and organizational excellence.

What is 5S Auditing?

5S auditing is a systematic assessment that scrutinizes workspaces to gauge their alignment with the principles of Sort, Set in Order, Shine, Standardize, and Sustain.

These audits serve as a critical tool to evaluate the effectiveness of 5S implementation, identify areas for improvement, and reinforce a culture of cleanliness, organization, and efficiency within workplaces.

Interested in learning more about Weever?

Steps-by-Step Guide to Conducting Successful Audits

Successful 5S audits transcend mere assessments; they catalyze a culture of excellence, fostering continual improvement and reinforcing the principles of organization and efficiency within the workspace.

Conducting audits is a pivotal stage within the 5S methodology. This step involves a comprehensive evaluation of work areas to determine compliance with established criteria and ensure adherence to 5S principles.

Before conducting audits, it is recommended to:

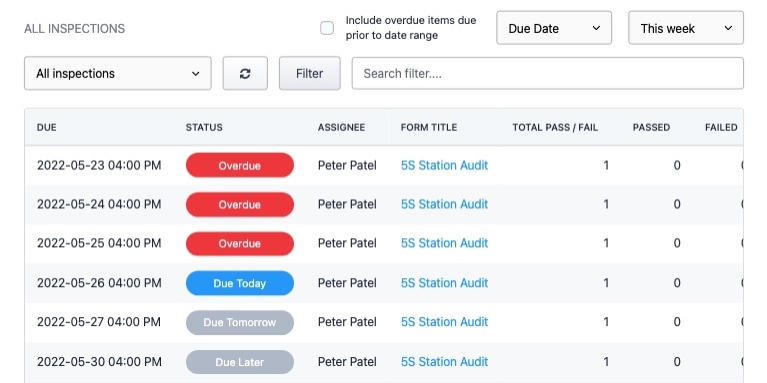

After completing audits, it is recommended to:

- Generate & Review Reports

- Implement Corrective Actions & Follow up Audits

- Celebrate Success and Recognition

Conducting thorough audits is not just about evaluating compliance; it's an opportunity to engage employees, gather valuable insights, and lay the groundwork for continuous improvement within the organization.

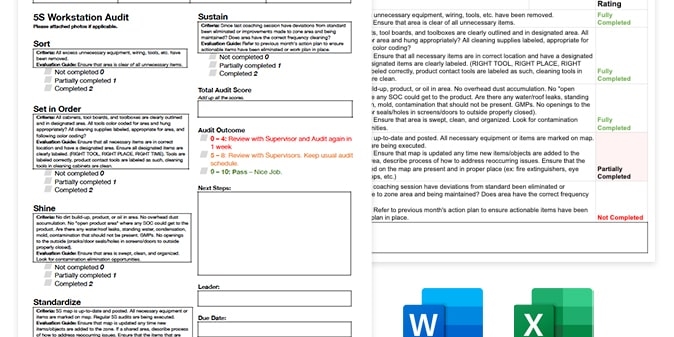

1. Preparation

Provide auditors with materials for them to efficiently understand the standards set for a give workstation.

- Gather Audit Materials: Ensure auditors have the necessary tools, checklists, and resources required for the assessment.

- Review Audit Scope: Familiarize auditors with the specific areas, processes, or departments to be audited.

2. Workstation Examination

Walk through the workstation with the operator and pay attention to the details.

- Objective Evaluation: Conduct evaluations in a structured manner, adhering strictly to the predefined criteria and checklists.

- Engage with Employees: Encourage auditors to interact with employees in the workspace, seeking their input and observations.

- Attention to Detail: Assess all aspects of the work area, from physical cleanliness to the organization of tools and materials.

3. Document Findings

Document observations. Add additional information for "failures", including photos and action item assignments if appropriate.

- Data Collection: Gather quantitative and qualitative data to support audit findings.

- Record Observations: Document both compliance and non-compliance observations accurately and objectively.

- Take Notes: Record any additional comments, suggestions, or noteworthy observations made during the audit.

4. Verify & Summarize

Include the operator in the audit. Discuss and verify audit results and consult on next steps. Summarize your observations and recommendations.

- Debriefing: Hold discussions with auditors to consolidate findings and ensure consistency in assessments.

- Employee Feedback: Share preliminary findings with employees to gather their insights and feedback.

- Double-check Observations: Review audit findings to ensure accuracy and validity.

- Cross-reference Data: Validate collected data with multiple sources if possible for accuracy.

- Summarize Findings: Consolidate audit observations and data into a comprehensive report.

- Include Recommendations: Offer suggestions for improvement and actions to address non-compliance areas

5. Communicate Results

Share insights and suggested action plans with shift supervisor and other stakeholders.

- Feedback Loop: Share audit reports and findings with relevant stakeholders, including employees and management.

- Transparent Communication: Ensure open communication about both strengths and areas needing improvement.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware