Best Practices for Manufacturers Developing Your Audit Checklist

Discover best practices for developing audit checklists in manufacturing. Learn how Weever digitizes and streamlines the process for optimal efficiency.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Manufacturing is dynamic; thus, operational excellence is essential for competitiveness and quality. Audit checklists, which assess compliance, monitor procedures, and identify opportunities for improvement, are essential to this endeavor. These checklists help ensure that every aspect of production meets strict standards and no detail is ignored. They are crucial to promoting excellence and improvement.

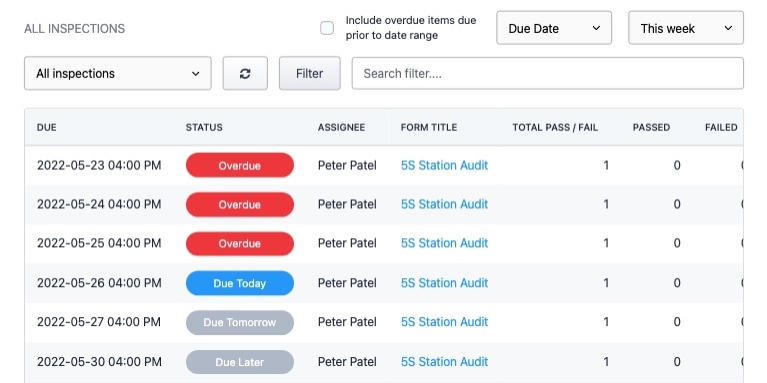

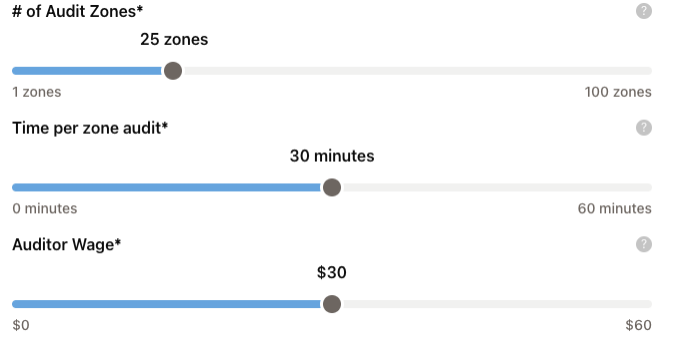

Weever's software digitizes audit checklists, revolutionizing manufacturers' auditing. Weever streamlines paper audits into digital ones. This change saves time, lowers errors, and improves audit protocol adaptability. Manufacturers can quickly build and update their digital checklists to address new issues and regulatory changes using Weever, ensuring audits are always current and complete. In an ever-changing sector, manufacturers need this auditing agility to maintain and improve operational excellence.

To learn more about Weever's digital solutions, including 5S auditing software, refer to here.

What is an Audit Checklist Good For? Absolutely Manufacturing!

An audit checklist is a structured tool used to evaluate and assess a workspace's adherence to your workplace methodologies, be they 5S or other lean methodologies, safety audits, and more. An audit checklist serves as a comprehensive guide for auditors to systematically inspect various areas, processes, or departments within an organization to ensure they align with the standards and practices dictated by management.

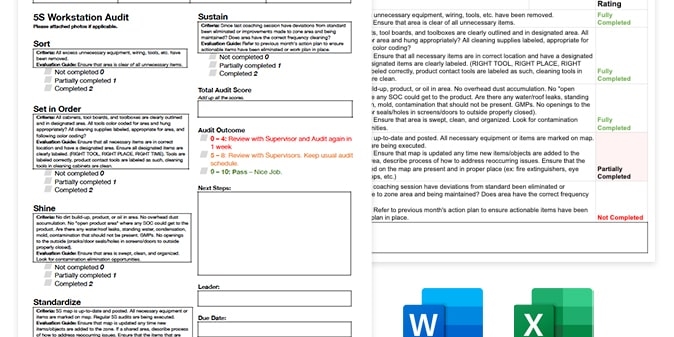

Consider a 5S audit checklist. A 5S audit checklist evaluates a workspace's 5S principles: Sort, Set in Order, Shine, Standardize, and Sustain. The checklist usually has sections for each 5S concept with particular items or requirements. These items use "Pass/Fail" scoring to describe 5S principle compliance or non-compliance. The checklist's Set in Order section may read:

- Locations for tools, equipment, paperwork, furniture, and materials are clearly marked and labeled and stowed properly when not in use

- Are there required tools or equipment that are NOT in their specified location? Check for inventory and equipment that are out of place/location.

- Abnormal or NOT OKAY conditions are easily identified from OKAY flow, process, and conditions. Stop switches, breakers, and emergency equipment are highly visible and located for easy access in case of emergency

The checklist acts as a roadmap for auditors during assessments, guiding them through specific criteria to evaluate, document findings, and identify areas for improvement or commendation. It aids in ensuring consistency, objectivity, and thoroughness in evaluating the workspace against 5S principles. Weever offers a free 5S audit template, which can be downloaded here.

Another example is a workplace safety audit checklist. A safety audit checklist for manufacturing is an organized tool designed to review and enhance safety protocols within manufacturing environments. It acts as a comprehensive reference for either internal or external auditors to spot potential safety risks, evaluate the effectiveness of risk management practices, and confirm adherence to local, national, and international safety regulations.

A safety audit checklist encompasses a wide range of areas within a manufacturing facility, but may include:

- Housekeeping and Organization: This part of the checklist ensures that work areas are clean and uncluttered. It includes checks for prompt cleaning of spills and debris and verifies proper storage of tools and equipment.

- Stored Materials: The checklist requires auditors to check that materials are stacked and spaced correctly to avoid incidents involving falling objects or improper storage.

- Electrical Equipment: It includes the examination of electrical devices to ensure they are regularly inspected, tested, and compliant with both company policies and safety standards.

- Job Design: This section assesses job roles to identify potential sources of injury and suggests job designs that reduce repetitive motion injuries.

- Compliance Gaps: The checklist highlights safety requirements to bridge compliance gaps and proposes measures to boost overall safety.

- Safety Standards: It verifies that workspaces meet established industry health and safety norms.

Learn more about Weever's safety audits and inspections here.

Manufacturing the Perfect Audit Checklist: Audit Criteria

Clear audit criteria must be established before creating audit checklists for each manufacturing workstation. Each workstation is evaluated against these requirements. Criteria must be tailored to different job areas and departments. The work done in one area may determine its criticality.

Good audit criteria are essential to creating quality audit checklists that increase industrial safety and efficiency. These criteria are rules, standards, or quantitative features used to evaluate and measure workplace approach effectiveness.

Here are some guidelines for developing audit criteria:

Define Specific Standards for Your Manufacturing Operation

Define clear guidelines or standards for organizing and maintaining workspaces. For example, outline what distinguishes necessary from unnecessary items in your manufacturing operations strategy.

Be Clear and Precise

Ensure that the auditing criteria are clear, precise, and easily understood by auditors. Remove ambiguity to prevent varying interpretations during audits.

Incorporate Diverse Metrics

Utilize both numerical and descriptive metrics in the criteria. Numerical metrics might include counts (e.g., expected number of items per workspace), while descriptive metrics could assess the state of cleanliness or organization visually.

Set Documentation Standards

Define any necessary documentation protocols. For example, establish guidelines for labeling items, arranging workstations, maintaining cleaning schedules, and how written documentation is created, updated, and accessed.

Alignment with Manufacturing Objectives

Ensure that the audit guidelines are in line with your operation's broader goals. These criteria should support desired outcomes such as improved manufacturing efficiency, enhanced safety, and better workspace organization.

Adapting to Change

Build flexibility into your guidelines to allow for adjustments and enhancements over time. Auditing guidelines should adapt as the organization evolves and should continuously reflect industry best practices.

Education and Communication

Communicate the audit criteria effectively to auditors through training and clear documentation. Ensure they comprehend and can apply these guidelines uniformly during audits.

Leverage Digitized Audit Checklists for Manufacturing with Weever

Creating detailed audit criteria for each manufacturing workstation might be challenging. Given the size of today's manufacturing environments, paper-based systems may be too complicated or expensive to establish or maintain. Precision and efficiency in audit processes are crucial to operational performance. Technology-based audit checklist management platforms like Weever improve accuracy, save time, and ensure consistency. Weever's software digitizes checklists to reduce human error and standardize processes across departments, ensuring all teams meet high standards. Real-time updates and automated alerts assist correct deviations, improving audit dependability.

Weever's flexible solutions allow audit checklist adaptation to meet operational needs without the complexity of traditional configurable. As your industrial environment changes, your auditing processes can adjust quickly to meet current legislation and internal standards.

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo