How to Use a 5S Audit Scorecard in Manufacturing to Drive Staff Participation

Boost staff engagement in manufacturing using a 5S audit scorecard. Learn how Weever’s configurable solution enhances participation and drives success.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

For manufacturers, efficiency and organization are key. Implementing the 5S methodology—Sort, Set in order, Shine, Standardize, and Sustain—can transform workplaces, leading to improved productivity, safety, and morale. A critical tool in maintaining these principles is the 5S audit scorecard. By leveraging a configurable 5S audit scorecard, manufacturers can significantly boost staff participation and engagement, ultimately driving the success of the 5S initiative. Let’s explore how to effectively use a 5S audit scorecard to enhance staff involvement, supported by Weever’s user-friendly software.

You can learn more about Weever’s 5S Audits solutions here.

Understanding the 5S Audit Scorecard in Manufacturing

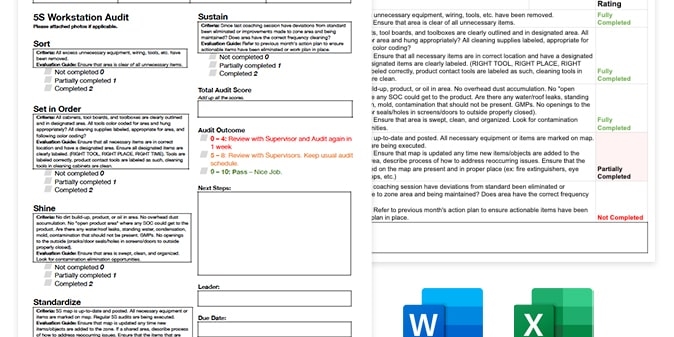

A 5S audit scorecard is a structured checklist used to evaluate adherence to the 5S principles. It provides a standardized method to assess and score various aspects of workplace organization and cleanliness. The scorecard typically covers criteria for each of the five S's, ensuring that all areas are consistently maintained.

Why Should Manufacturers Use a 5S Audit Scorecard?

- Consistency: The scorecard ensures that all audits are performed uniformly, maintaining high standards across the board, and improving the quality of the collected data.

- Accountability: Regular audits create a sense of responsibility among staff, encouraging them to uphold 5S principles.

- Continuous Improvement: The scorecard helps identify areas that need improvement, fostering a culture of continuous improvement.

Driving Manufacturing Staff Participation with a 5S Audit Scorecard

Engaging staff in the 5S process is crucial for its success. Here’s how a 5S audit scorecard can drive participation:

Clear Expectations and Transparency

A well-structured 5S audit scorecard sets clear expectations for staff. When employees understand the specific criteria they are being evaluated on, they are more likely to take ownership of their workspaces. Transparency in the scoring process fosters trust and motivates staff to consistently meet or exceed the standards.

Regular Feedback and Recognition

Using a 5S audit scorecard allows for regular feedback on performance. This feedback loop is essential for maintaining momentum. Recognizing and rewarding teams or individuals who achieve high scores reinforces positive behavior and encourages others to follow suit.

Involvement in the Audit Process

Involving staff in the audit process itself can significantly boost engagement. When team members participate in audits, they gain a deeper understanding of the 5S principles and see firsthand the impact of their efforts. This hands-on involvement can lead to greater commitment to maintaining 5S standards, and greater ownership by staff over their workflows.

Training and Education

The 5S audit scorecard can also be a valuable training tool. By highlighting areas for improvement, it provides concrete examples that can be used in training sessions. Ongoing education helps staff understand the importance of each of the 5S principles and how they contribute to overall efficiency and productivity.

Weever’s Configurable Solution for 5S Audits

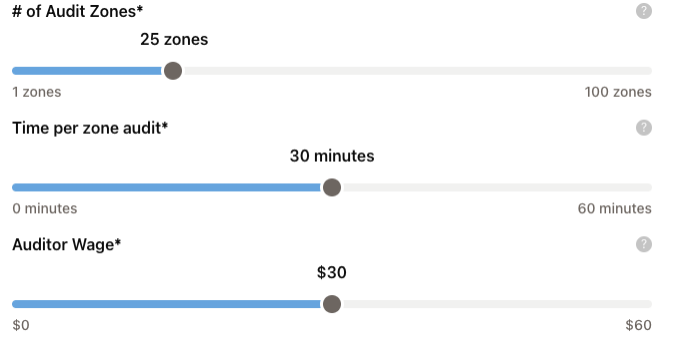

Weever’s configurable software enhances the 5S audit process, making it easier for manufacturers to engage their staff. Here’s how:

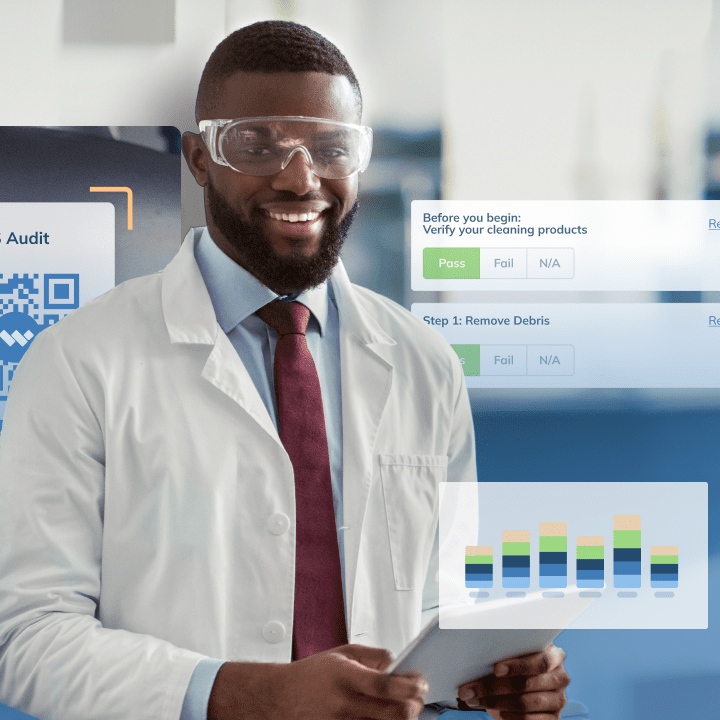

User-Friendly Interface

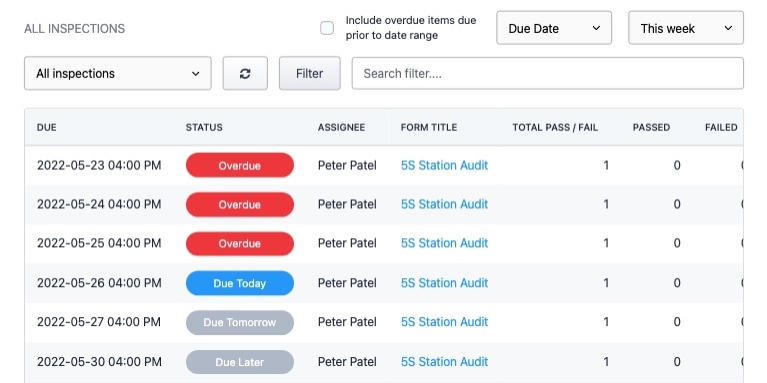

Weever’s solution offers an intuitive interface that simplifies the audit process. Staff can easily navigate the scorecard, input data, and track performance over time. This ease of use reduces resistance to the audit process and encourages more frequent participation.

Configurable Scorecards

While standardization is crucial, flexibility is also important. Weever allows for configurable scorecards that can be tailored to specific manufacturing environments. This configurability ensures that the scorecard is relevant to the unique needs of each workspace, making it more meaningful for staff.

Real-Time Data and Reporting

Weever’s solution provides real-time data and reporting, giving instant feedback on audit results. This immediate visibility helps teams quickly address any issues, maintain high standards, and recognize improvements. Real-time reporting also facilitates better communication between management and staff. The collected data available on the cloud can be used for reporting by business analysts, managers, and executives.

Seamless Integration

Weever’s software integrates seamlessly with other business systems, ensuring that the 5S audit process can be incorporated into a greater operational workflow. This integration minimizes disruption and encourages staff to view 5S as an integral component of their daily routines.

Driving Staff Engagement in Manufacturing with 5S Audit Scorecards Now and into the Future

Implementing a 5S audit scorecard is a powerful strategy to drive staff participation and engagement in manufacturing. By setting clear expectations, providing regular feedback, involving staff in the process, and using it as a training tool, manufacturers can sustain high standards of workplace organization. Supported by Weever’s user-friendly, configurable solution, the 5S audit process becomes more efficient and engaging, ultimately contributing to the overall success of the 5S initiative. Embrace the power of the 5S audit scorecard and watch as your manufacturing operations become more organized, efficient, and productive.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo