How to Shine in 5S

A Practical Guide to Ensuring Workstations are Clean and Standardized for Success.

5S Overview

5S Planning

5S Implementation

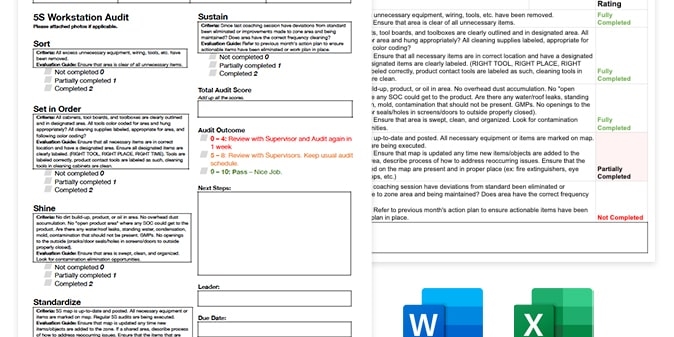

5S Auditing

5S Audit Digitization

FREE RESOURCEs

In the realm of workplace organization and efficiency, the 5S methodology stands as a beacon for optimal operations.

Among its five pillars—Sort, Set in Order, Shine, Standardize, and Sustain—Shine holds a crucial position in maintaining cleanliness, safety, and functionality within workstations.

Let’s delve into the specifics of this essential step and explore how it drives the 5S methodology toward excellence.

How to Shine

Among the 5S steps, Shine (Seiso in Japanese) refers to the process of cleaning and inspecting work areas and equipment thoroughly. It's more than just tidying up—it's about ensuring that every nook and cranny is pristine, free of dust, dirt, or potential hazards. By doing so, Shine contributes significantly to a workspace's overall safety, functionality, and morale.

Step-by-Step Guide to 5S Shine

Cleaning and tidying can be completed in a multitude of different ways. The below steps outline the most efficient way to ensure the best results.

1. Preparation

Before diving into the cleaning process, gather the necessary supplies—cleaning agents, tools, safety gear, and waste disposal materials.

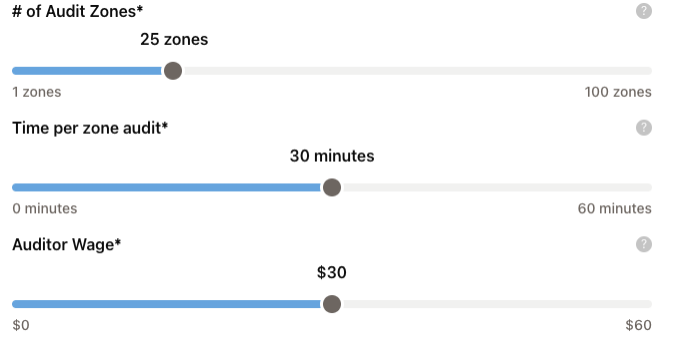

2. Schedule Regular Cleaning Sessions

Establish a routine for cleaning that suits the specific needs of your workstation. Daily quick sweeps and weekly deeper cleanings can help maintain cleanliness without disrupting operations.

3. Clear the Workspace

Remove all items from the area, ensuring a clear and unobstructed cleaning path.

4. Cleaning Process

- Start from the top and work your way down to avoid re-contaminating cleaned areas.

- Use appropriate cleaning agents and tools for different surfaces and equipment.

- Pay extra attention to commonly overlooked areas such as corners, shelves, and under equipment.

- Inspect for any signs of wear, damage, or potential safety hazards during cleaning.

Interested in learning more about Weever?

Best Practices for the Shine 5S Step

Embracing the Shine step in the 5S methodology not only enhances the visual appeal of a workspace but also elevates operational efficiency and safety standards. By maintaining a clean and organized environment, organizations pave the way for sustained success and a culture of excellence.

Remember, the true essence of Shine lies not just in the gleam of a polished surface, but in the commitment to a mindset of cleanliness and continuous improvement

Ownership and Accountability

Assign responsibilities for cleaning and maintenance to individuals or teams to ensure accountability.

Continuous Improvement

Encourage feedback and suggestions from employees to refine the cleaning process continually.

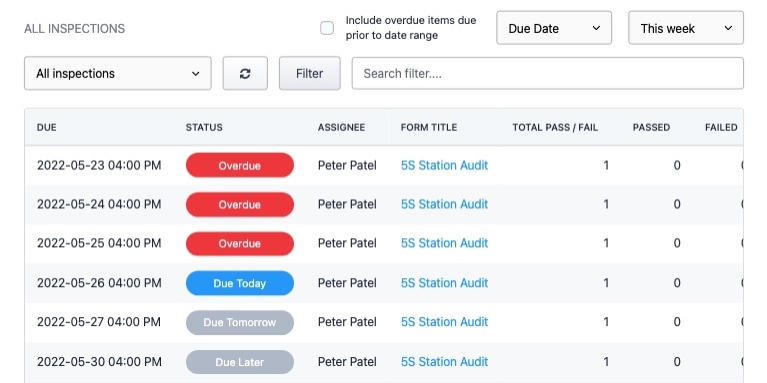

Regular Inspections

Implement regular checks to ensure adherence to cleanliness standards and promptly address any issues identified.

Training and Education

Provide adequate training on proper cleaning techniques, safety procedures, and the importance of maintaining a clean workspace.

Sustainability

Instill a culture of cleanliness and continuous improvement by integrating Shine into daily routines.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo