The Importance of an Audit Checklist in Manufacturing Operations

Learn how audit checklists ensure compliance, enhance quality, and boost efficiency in manufacturing. Discover Weever’s configurable solutions for effective audits.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Success in manufacturing requires upholding high standards. Extensive standards for efficiency, safety, and quality should be met by each product before it leaves the factory. This is where audit checklists come in. They are essential tools that help manufacturers keep track of their operations, ensuring that every step in the process adheres to set standards.

Audit checklists play a vital role in manufacturing by making sure all activities comply with industry regulations. They help identify and correct errors before they become major problems, which ensures products are consistently high-quality. Additionally, these checklists boost efficiency by streamlining processes and eliminating waste.

In this blog, we will explore how audit checklists help ensure compliance, enhance quality, and improve efficiency in manufacturing processes. We'll show you why these checklists are indispensable for maintaining the highest standards in your operations.

Ensuring Compliance in Manufacturing with Audit Checklists

Manufacturing must adhere to regulations in order to guarantee worker safety and fulfill industry requirements. Audit checklists are essential tools that assist manufacturers in maintaining compliance by offering a systematic method to examine procedures and detect any problems.

They make sure that all activities follow the rules, which keeps expensive fines and production stops at bay.

Observation forms and near miss reporting software like Weever, further support compliance by capturing potential hazards and incidents. This proactive approach helps manufacturers address issues promptly, maintaining a safe and compliant work environment.

Ensuring Quality in Manufacturing with Audit Checklists

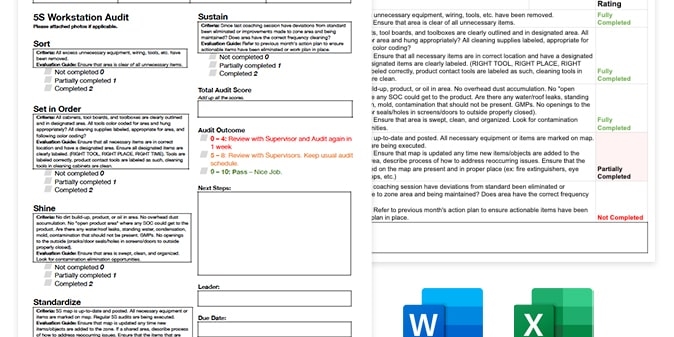

Audit checklists are critical for ensuring and enhancing product quality. They assist in identifying and correcting problems before they have an impact on the finished output. The 5S audit scorecard is an effective tool for promoting a clean, organized, and efficient workplace, which is critical to high-quality manufacturing.

Integrated work systems further enhance quality by streamlining processes, ensuring that every step is consistent and efficient. This combination of tools and systems helps manufacturers produce top-notch products every time.

Boosting Efficiency in Manufacturing with Audit Checklists

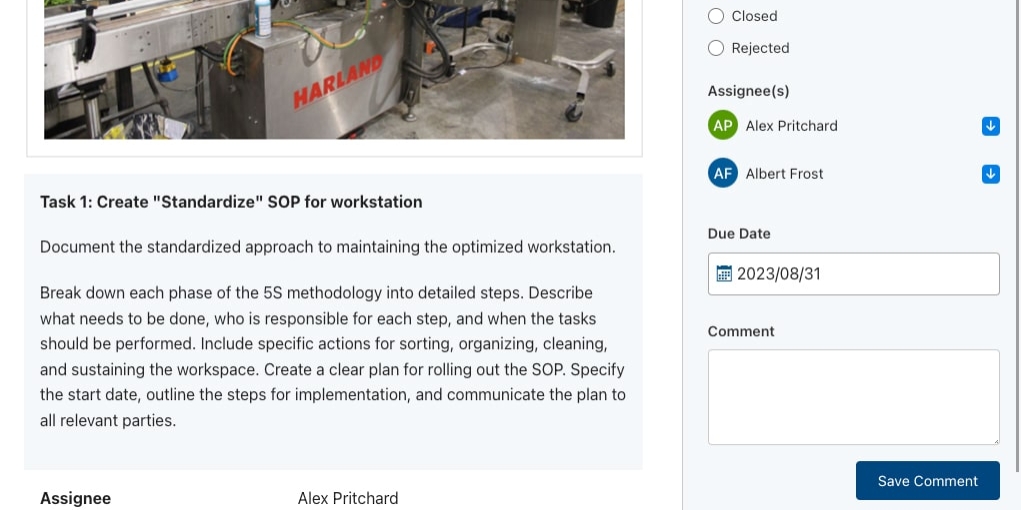

Audit checklists are essential for identifying and eliminating bottlenecks and inefficiencies in manufacturing processes. By regularly reviewing operations, these checklists help pinpoint areas that need improvement. Using program templates standardizes procedures, making workflows smoother and more efficient.

Predictive maintenance also plays a key role in boosting efficiency. By anticipating and addressing equipment issues before they cause downtime, manufacturers can keep operations running smoothly and avoid costly interruptions. Together, these tools and strategies ensure a highly efficient manufacturing process.

How Audit Checklists Promote Proactive Measures and Continuous Improvement

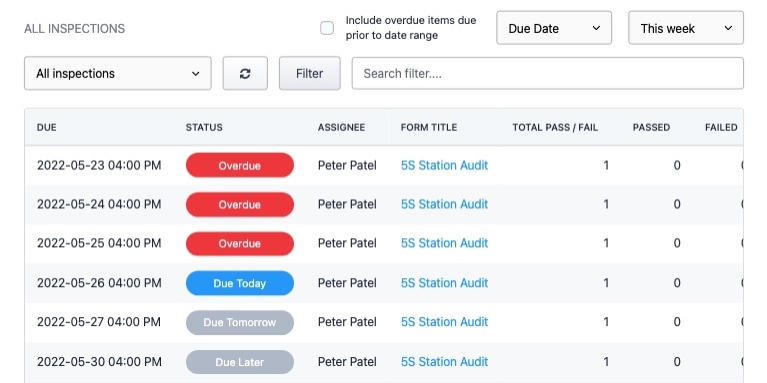

Taking proactive measures is crucial in manufacturing to prevent issues before they occur. Audit checklists are essential for this purpose. By conducting regular audits, manufacturers can identify potential problems early and address them promptly, avoiding costly disruptions and ensuring smooth operations.

Regular use of audit checklists supports continuous improvement by providing consistent feedback on processes. This helps manufacturers pinpoint areas needing enhancement and implement changes that boost efficiency and quality over time.

Near miss reporting software complements these efforts by capturing potential hazards before they become serious issues. This software allows workers to report near misses, which are then analyzed to prevent future incidents. By integrating these proactive tools and practices, manufacturers can create a safer, more efficient, and continuously improving work environment.

Weever’s Configurable Solutions for Effective Audits

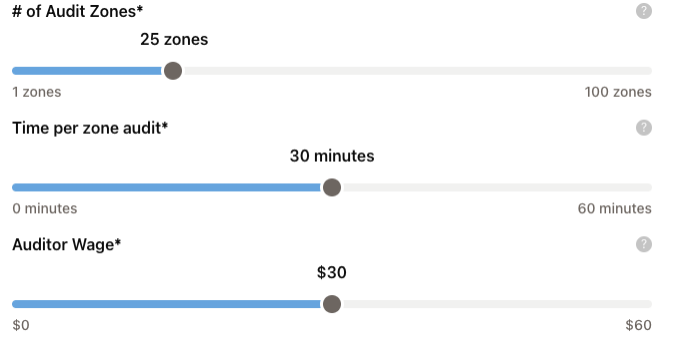

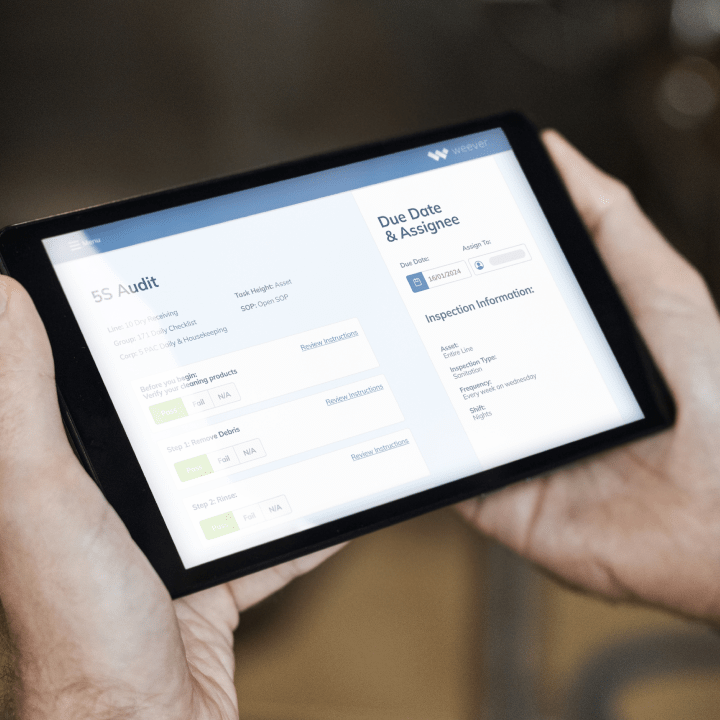

Adopting configurable solutions for audit checklists in manufacturing offers many benefits. These checklists can be tailored to fit the specific needs of different processes, ensuring a perfect match for every operation. Weever’s configurable solutions allow manufacturers to configure their audits, making them more relevant and effective.

For example, a factory can design checklists to focus on particular safety protocols, quality checks, or maintenance schedules. This flexibility ensures all critical areas are covered thoroughly. With Weever’s solutions, manufacturers can streamline their audit processes, improve compliance, and boost overall efficiency. These tailored checklists make it easier to maintain high standards and continuously improve operations.

Ensuring Compliance, Quality, and Efficiency in Manufacturing Operations with Audit Checklists

Audit checklists are critical tools for maintaining good production standards. They contribute to compliance with industry laws, improved product quality, and increased operational efficiency. Checklists avoid severe problems and streamline procedures by detecting and addressing errors early on. They also contribute to continual improvement by offering frequent input on operations.

Tools like observation forms and near miss reporting software aid in compliance and proactive issue resolution. The 5S audit scorecard promotes an organized workspace, while integrated work systems ensure consistent quality. Predictive maintenance helps avoid downtime, and maintain smooth operations. Weever’s configurable solutions allow manufacturers to tailor checklists to their specific needs, enhancing audit effectiveness and overall efficiency. These strategies ensure manufacturers can maintain high standards and continuously improve their processes.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo