Leveraging 5S Audit Scorecards for Continuous Improvement

Enhance manufacturing efficiency with Weever's 5S audit scorecards. Streamline audits, automate workflows, and leverage real-time data for continuous improvement.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Optimizing operations and maintaining peak efficiency is paramount in the manufacturing industry. A proven strategy to achieve this is through consistent improvement initiatives bolstered by regular 5S audits and scorecards. By systematically evaluating operations and providing actionable feedback, manufacturers can significantly enhance their processes. This article explores how 5S audit scorecards drive continuous improvement and how Weever software simplifies this process.

New to 5S? Learn more with Weever’s Ultimate Guide to Success with 5S, and get started building a business case for a 5S program at your manufacturing facility with a free 5S Audit Checklist template.

The Power of 5S Audits in Continuous Improvement

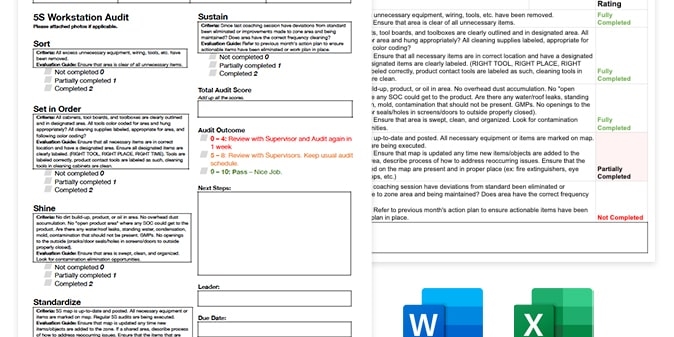

The 5S methodology — Sort, Set in order, Shine, Standardize, and Sustain — is the cornerstone of a well-organized and efficient workplace. Regular 5S audits ensure these principles are consistently upheld. By frequently assessing operations, manufacturers can pinpoint areas for improvement, eliminate waste, and streamline workflows.

5S audit scorecards are instrumental in this process. They offer a structured framework to evaluate 5S adherence, highlighting strengths and weaknesses. This consistent assessment fosters a culture of continuous improvement where feedback is used to enhance operational efficiency and safety.

Learn more about 5S Audit Programs with Weever.

How Weever Software Enhances 5S Audit Management

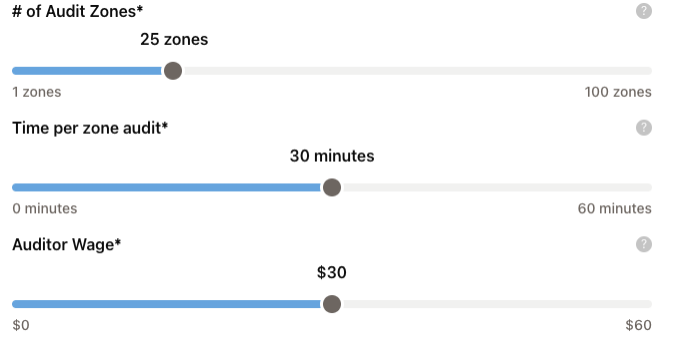

Weever software provides a comprehensive solution for creating and managing 5S audit scorecards, simplifying the audit process for manufacturers. Here's how Weever streamlines 5S audits:

- Configurable 5S Audit Scorecards: Weever allows manufacturers to configure audit scorecards to align with specific operational needs. This flexibility ensures scorecards accurately reflect individual requirements and standards. Scorecards can be easily modified to adapt to evolving improvement goals.

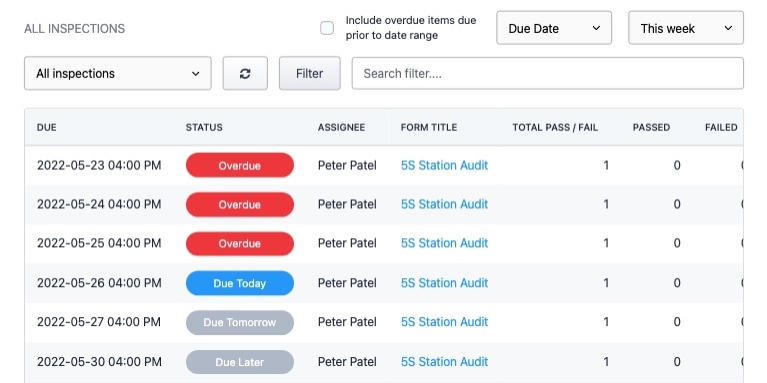

- Automated Workflows for Efficient Audits: Weever's automated workflows streamline the audit process by ensuring each step is executed efficiently and systematically. Identified actions and improvements are promptly addressed, minimizing delays between audit completion and corrective action.

- Real-time Reporting and Data Analysis: Effective continuous improvement hinges on real-time reporting and data analysis. Weever provides valuable insights and trends from 5S audits, enabling data-driven decision-making. The software's data analysis capabilities highlight recurring issues, track progress over time, and uncover opportunities for further optimization.

Implementing 5S Audit Scorecards with Weever Software: A Step-by-Step Approach

Weever software facilitates a smooth and effective 5S audit scorecard implementation. Follow these steps:

- Assessment and Planning: Evaluate current 5S practices and identify key improvement areas. Develop a plan outlining the 5S audit program's objectives and how Weever software will be utilized.

- Designing Scorecards: Use Weever's tools to create audit scorecards aligned with operational standards. Include relevant criteria for each 5S principle to ensure comprehensive evaluation.

- Training and Onboarding: Train the team on Weever software and the importance of 5S audits. Provide clear instructions on conducting audits, recording findings, and effectively using software features.

- Conducting Audits: Schedule regular audits and assign responsible personnel. Utilize Weever software to guide the audit process, ensuring consistency and thoroughness.

- Reviewing Results and Taking Action: Analyze audit results using Weever's reporting tools. Identify areas requiring attention and implement corrective actions. Leverage automated workflows for timely issue resolution.

- Continuous Monitoring and Improvement: Regularly assess the 5S audit program's effectiveness. Use Weever's data insights to refine the process and drive ongoing improvement.

Continuous Improvement is Essential for Manufacturing Excellence

By leveraging 5S audit scorecards, manufacturers can ensure consistent 5S adherence, identify improvement areas, and boost efficiency. Weever software enhances this process with configurable scorecards, automated workflows, and real-time data analysis, making it an invaluable tool for manufacturers committed to continuous improvement. Embrace the power of 5S audits with Weever software to elevate manufacturing operations to new heights of excellence. Adopting a 5S program to drive digital transformation is easier than it seems, no matter your manufacturing operation. In just 3 weeks, archaic paper-based methodologies can be a thing of the past, with the Weever Accelerate Program.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo