The Importance of a 5S Audit Scorecard in Manufacturing Operations

Discover how 5S audit scorecards and Weever software streamline audits, drive continuous improvement, and enhance operational excellence in manufacturing.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Maintaining a clean, organized, and efficient manufacturing environment is critical for operational excellence. One powerful tool that supports these goals is the 5S audit scorecard. 5S audit scorecards not only helps sustain high standards of cleanliness and organization but also drives continuous improvement across manufacturing operations. In this post, we'll explore the significance of the 5S audit scorecard and how Weever software facilitates its creation and management, ensuring manufacturers can maintain peak efficiency effortlessly.

The Role of a 5S Audit Scorecard in Manufacturing

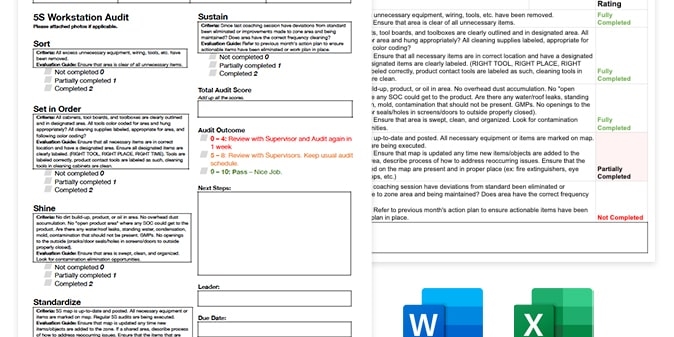

The 5S methodology—Sort, Set in order, Shine, Standardize, and Sustain—is essential for creating a well-organized workplace. Regular audits using a 5S scorecard ensure these principles are consistently applied, promoting an environment that is not only clean but also optimized for efficiency and safety.

Driving Continuous Improvement

A 5S audit scorecard provides a structured framework for evaluating adherence to 5S principles. By systematically assessing work areas, manufacturers can identify strengths and weaknesses, enabling targeted improvements. This continuous feedback loop fosters a culture of ongoing enhancement, where every audit contributes to operational excellence.

Enhancing Operational Excellence

Consistent use of 5S audit scorecards helps eliminate waste, streamline processes, and improve workflow efficiency. By regularly evaluating and refining operations, manufacturers can maintain high standards of productivity and quality, directly impacting their bottom line.

Simplifying 5S Audit Management with Weever Software

Weever software offers a comprehensive solution for creating and managing 5S audit scorecards. It streamlines the audit process, making it easier for manufacturers to conduct regular evaluations and uphold high standards. Here's how Weever simplifies 5S audit management:

Configurable Audit Scorecards

Weever software allows for the creation of configurable 5S audit scorecards, tailored to suit different manufacturing work areas of varying complexity. This flexibility ensures that the scorecards are relevant to specific operational needs, making the auditing process more effective and efficient.

Automated Workflows for Efficient Execution

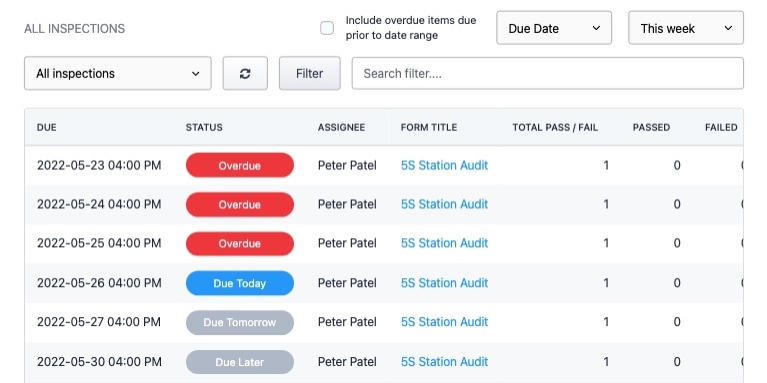

One of the standout features of Weever software is its automated workflows. These workflows guide users through the audit process, ensuring that each step is completed systematically. Identified actions and improvements are promptly addressed, minimizing delays and ensuring that corrective measures are implemented swiftly.

Real-time Reporting and Data Analysis

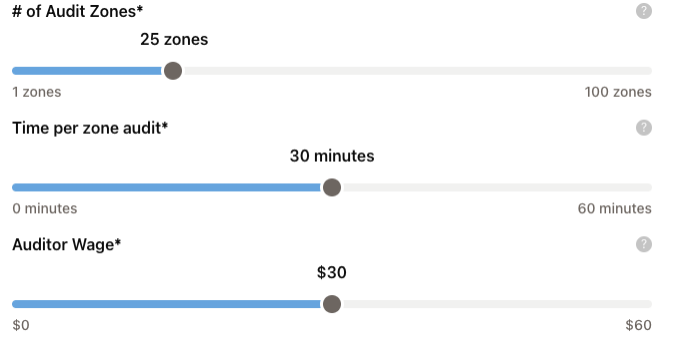

Effective continuous improvement relies on real-time reporting and data analysis. Weever software provides valuable insights and trends from 5S audits, enabling manufacturers to make data-driven decisions. This capability highlights recurring issues, tracks progress over time, and uncovers opportunities for further optimization.

Adopting the 5S Methodology with Weever Software

Implementing the 5S methodology in manufacturing operations can seem daunting, but with Weever software, the process is straightforward and efficient. Here’s a step-by-step approach to adopting 5S audit scorecards using Weever:

Step 1: Assessment and Planning

Begin by assessing your current 5S practices and identifying key areas for improvement. Develop a plan that outlines the objectives of your 5S audit program and how Weever software will be utilized to achieve these goals.

Step 2: Designing the Scorecards

Use Weever’s configurable tools to create audit scorecards that align with your operational standards. Ensure that each scorecard includes relevant criteria for each of the 5S principles, providing comprehensive coverage for all aspects of your work environment.

Step 3: Training and Onboarding

Train your team on the use of Weever software and the importance of 5S audits. Provide clear instructions on how to conduct audits, record findings, and utilize the software’s features effectively.

Step 4: Conducting Audits

Schedule regular audits and assign responsible personnel. Utilize Weever software to guide the audit process, ensuring consistency and thoroughness. The software’s user-friendly interface makes it easy for team members to perform audits efficiently.

Step 5: Reviewing Results and Taking Action

Analyze the audit results using Weever’s real-time reporting tools. Identify areas that require attention and implement corrective actions. Leverage automated workflows to ensure timely resolution of identified issues.

Step 6: Continuous Monitoring and Improvement

Regularly review the effectiveness of your 5S audit program. Use the data insights provided by Weever software to refine the process and drive ongoing improvements. This continuous monitoring ensures that your manufacturing operations remain at the forefront of efficiency and excellence.

The Weever Accelerate Program

Adopting Weever’s solution can be quick and seamless, with the Weever Accelerate Program enabling full implementation in as little as three weeks. This program ensures that manufacturers can transition from traditional, paper-based methodologies to a digital, streamlined 5S audit process rapidly, without disruption to their operations.

Supercharge Manufacturing with 5S Audit Scorecards

The 5S audit scorecard is a vital tool in maintaining a clean, organized, and efficient manufacturing environment. It supports continuous improvement and operational excellence by providing a structured framework for regular evaluation and feedback. Weever software enhances this process by offering configurable audit scorecards, automated workflows, and real-time data analysis, making it easier for manufacturers to uphold high standards effortlessly. By adopting the 5S methodology with Weever software, manufacturers can ensure a smooth and effective transition to a culture of continuous improvement, driving their operations to new heights of excellence.

Interested in deep diving 5S methodology? Read on with Weever’s Ultimate Guide to Success with 5S!

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo