What is 5S Auditing?

What is 5S auditing, how can it be practically implemented in a manufacturing and warehouse facility, and what are the best practices?

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

5S auditing plays a pivotal role in the sustained success of a 5S program, particularly in its "Sustain" phase. This phase, the fifth principle of the 5S methodology, underscores the importance of continually reinforcing the standards established through the initial four principles: Sort, Set in Order, Shine, and Standardize.

Sustain involves instilling a culture of consistency, discipline, and ongoing dedication to these principles, ensuring that the improvements achieved in workspace organization endure over time. It necessitates the establishment of habits, routines, and practices that uphold the prescribed standards of cleanliness, organization, and efficiency, thereby integrating the 5S principles into the fabric of the organization.

Sustaining the 5S principles demands regular reinforcement, training, monitoring, and a commitment to continuous improvement to safeguard against regression and facilitate lasting positive changes within the workspace. Despite being just one of the five principles, Sustain embodies the bulk of the work, holding the key to realizing tangible results. Conversely, it's also the stage where many 5S initiatives falter.

To fully harness the benefits of the 5S methodology, it is imperative to implement a robust 5S auditing program that efficiently and effectively ensures the sustained adherence to these principles.

6 Steps to Implementing a Successful 5S Auditing Program

If you have completed the first 4 "S" steps in the 5S methodology, the auditing program is essentially about normalizing that work on an ongoing basis.

Implementing a 5S auditing program involves 6 practical steps:

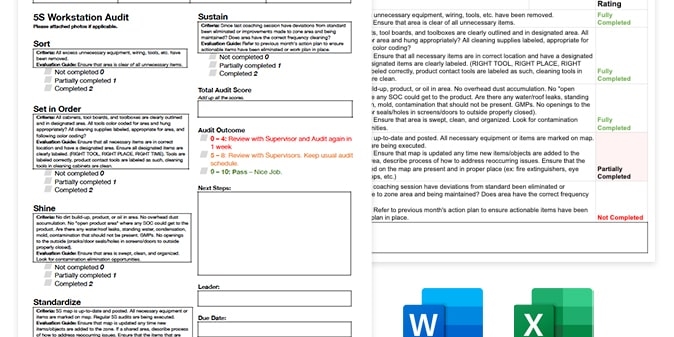

1. Establish Audit Criteria and Checklists

Establishing audit criteria that serve as the guidelines or standards against which the workspace will be evaluated during the audit process.

Use the criteria to develop checklists outlining specific items or areas to be evaluated under each of the 5S categories. This checklist helps auditors systematically assess the workspace.

2. Train Auditors

Ensure that the individuals conducting the audit are trained in the 5S principles, the audit process, and using the audit checklist effectively.

Communicate the established audit criteria clearly and ensure they understand how to apply the criteria consistently during audits. They should understand what to look for and how to assess compliance.

Also, train auditors on how to use the checklists effectively and communicate its purpose and importance to all involved stakeholders.

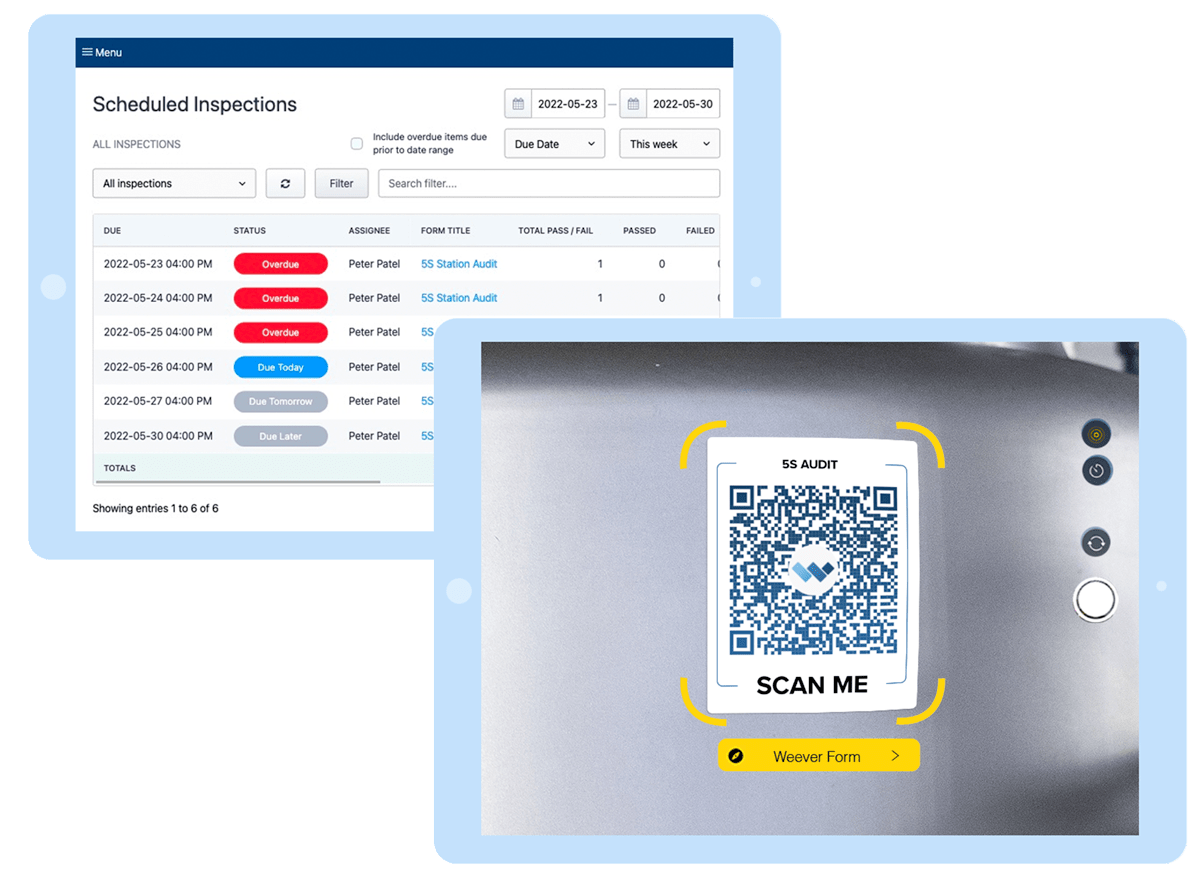

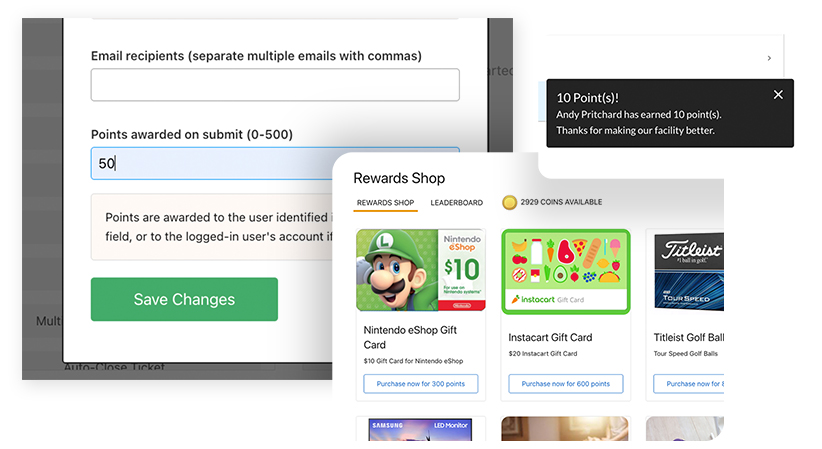

If you have digitized your 5S audit process using digital forms, you will need to train your auditors on how to access and use the system.

3. Schedule Audits

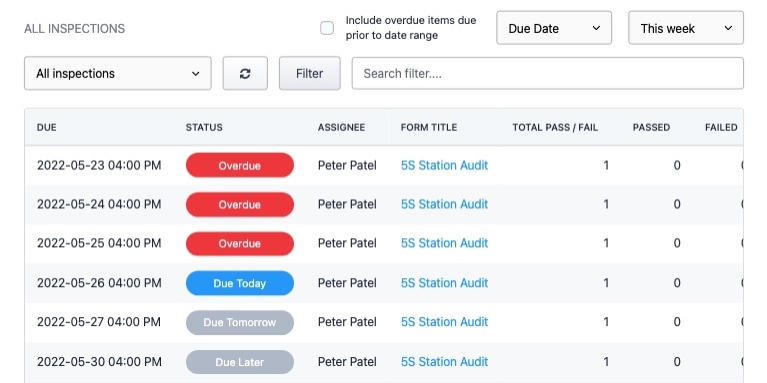

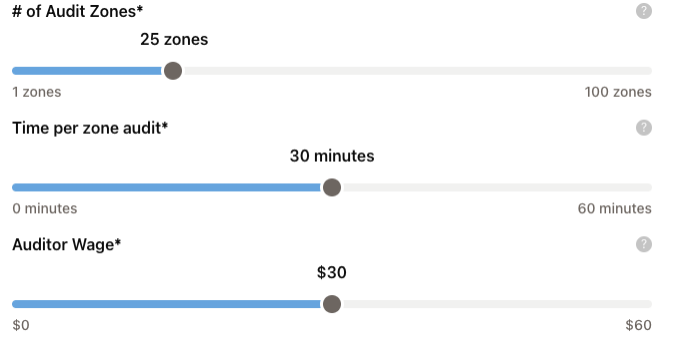

Establish a regular schedule for conducting audits. Scheduling audits in a systematic and consistent manner ensures that the workspace's adherence to 5S principles is regularly assessed, providing opportunities for improvement and sustaining the desired standards over time.

Decide on the frequency of audits based on the nature of the workspace, its size, complexity, and the organization's needs. Audits can occur daily, weekly, monthly, quarterly, or even semi-annually.

4. Conduct Audits

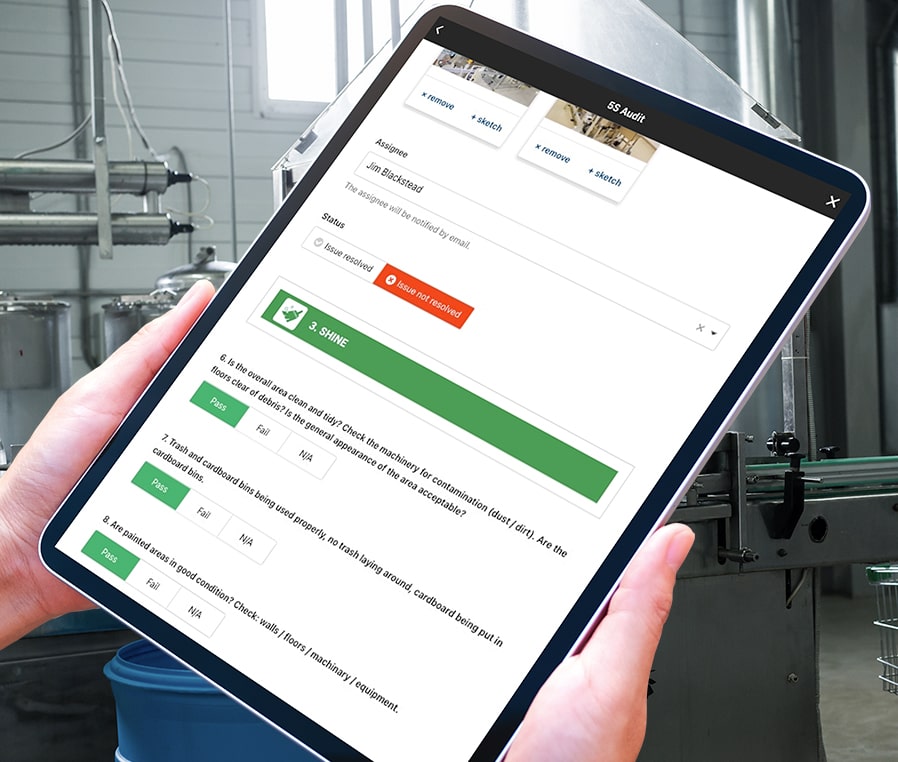

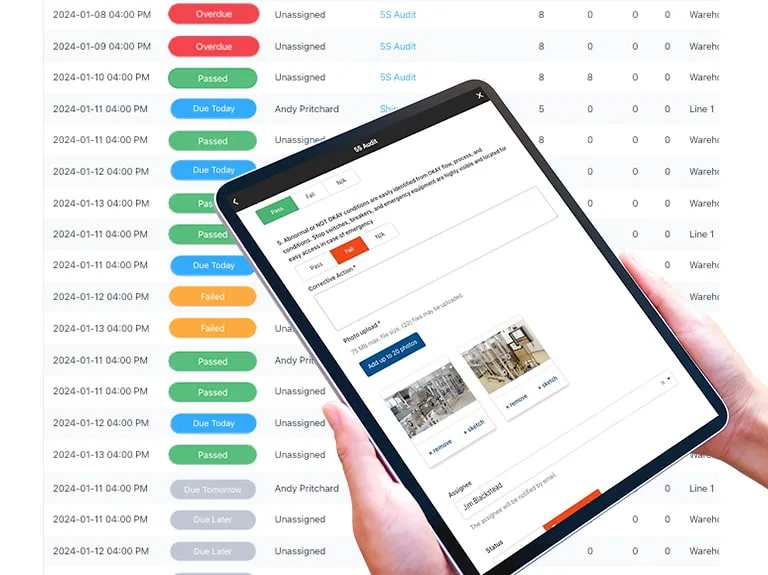

Perform the audits using the established checklist. Evaluate each area against the defined criteria for Sort, Set in Order, Shine, Standardize, and Sustain. Document findings, noting areas of compliance and areas needing improvement.

5. Generate & Review Reports

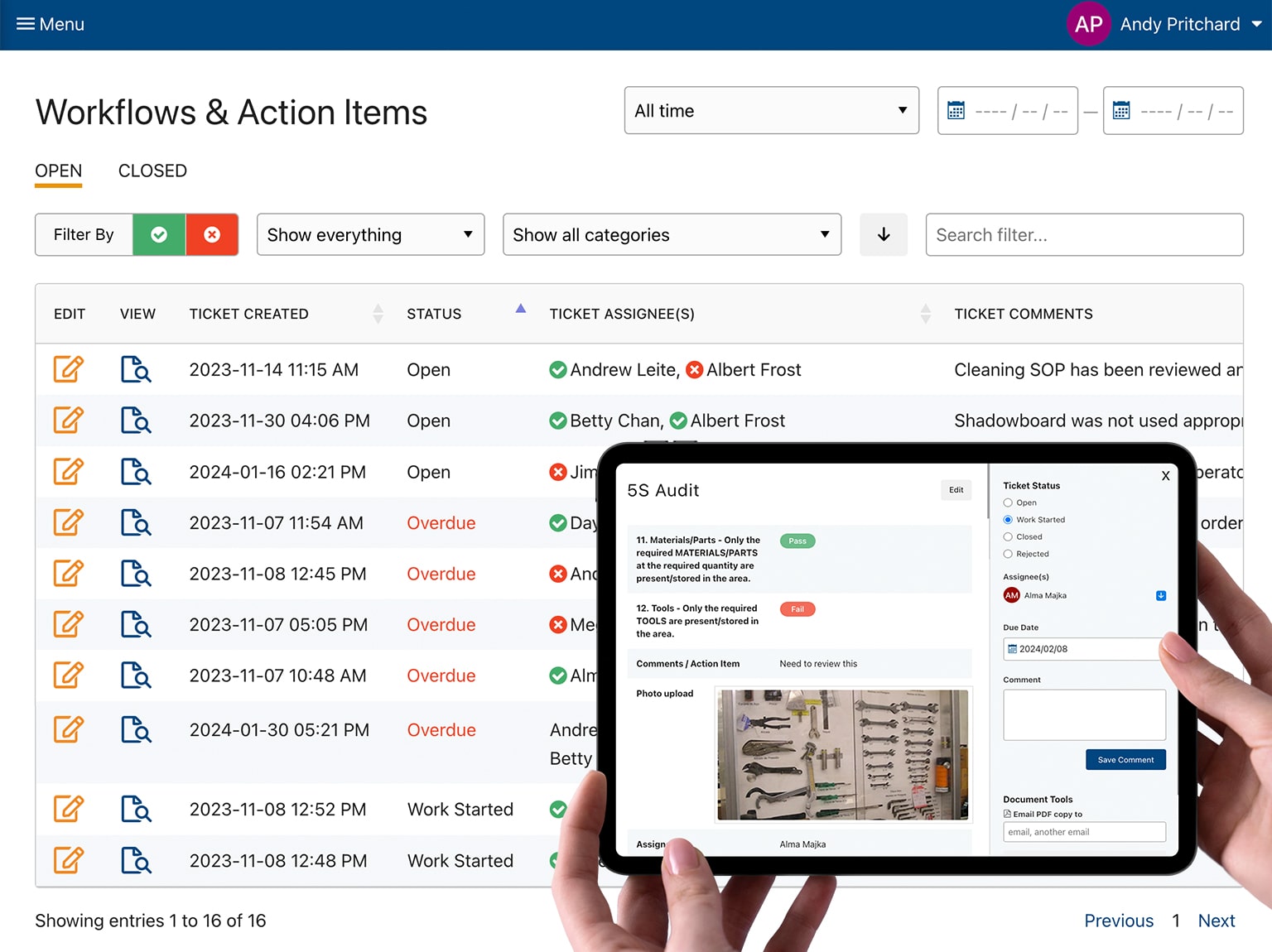

Compile audit findings into comprehensive reports. These reports should include observations, areas of non-compliance, improvement recommendations, and any notable successes.

Review the audit reports with relevant stakeholders, including employees working in the audited areas. Discuss findings, celebrate successes, and identify action items for improvement.

6. Implement Corrective Actions & Follow up Audits

Develop action plans to address areas identified for improvement. Assign responsibilities, set deadlines, and track progress on implementing necessary changes.

Conduct follow-up audits to assess the effectiveness of implemented changes and to track progress. Continuous monitoring ensures sustained adherence to 5S principles.

7. Celebrate Success and Recognition

Recognize and celebrate achievements and improvements resulting from the auditing process. Acknowledge the efforts of individuals and teams in maintaining an organized and efficient workspace.

Benefits of 5S Auditing

5S audits are critical because they are the vehicle through which standards are maintained. 5S audits also provide a means for frontline staff to provide feedback that drive continuous improvement and productivity gains. The benefits of 5S audits are vast, including:

Maintenance of Standards

Ensure established 5S standards are maintained. Prevent regression into disorganization. Provide a structured way to measure how effectively the 5S principles are being applied.

Identify Improvements

Capture issues in the 5S implementation as well as other challenges affecting productivity in general and create an action plan to overcome them.

Employee Engagement

Foster a sense of ownership and responsibility and encourage team members to take an active role in maintaining the workspace's cleanliness and organization.

Data-Driven Decision Making

Audit results provide rich data and insights to drive strategic decisions around resource allocation, OEE, employee engagement and so forth.

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo