Measure the Real Impact of your 5S Audits with Cycle-based Activity Timing

5S Overview

5S Planning

5S Implementation

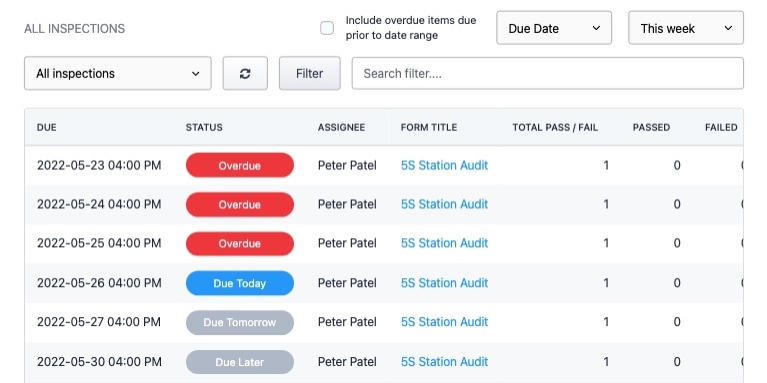

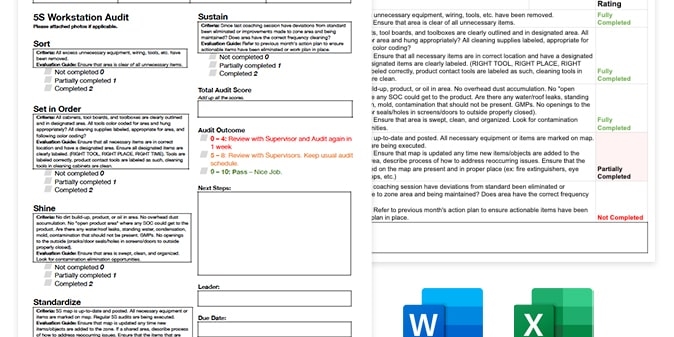

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Improving the efficiency of workstations is critical for businesses to increase their Overall Equipment Effectiveness (OEE).

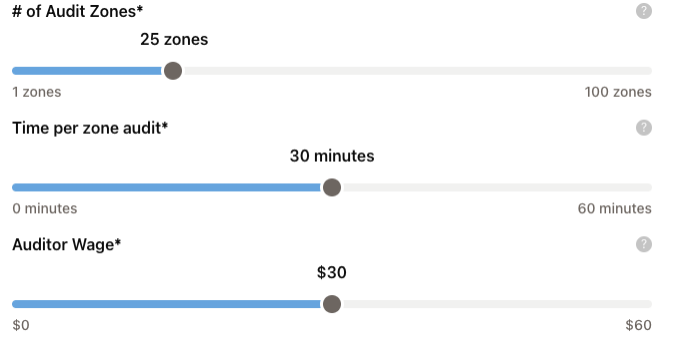

However, the challenge lies in justifying the time and money invested in Lean initiatives, often because the benefits of these initiatives are not tangible, which makes it difficult to prove their return on investment (ROI).

The 5S methodology is one such initiative that aims to optimize the efficiency of workstations by removing clutter and redundant items, organizing the workspace, and standardizing the approach.

This system has proven effective in not only increasing efficiency and productivity but also reducing defects and waste, increasing employee engagement and retention.

However, site managers often ask for tangible proof of the ROI, which poses a challenge for Continuous Improvement (CI) managers.

How can cycle times help?

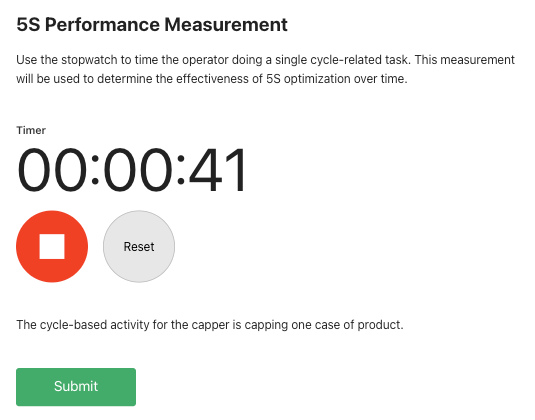

To address this issue, CI managers can use cycle-based activity timing during 5S audits.

Cycle time is the duration of one production cycle, and it can be used as a metric to identify improvement opportunities in a manufacturing process.

By measuring cycle time, managers can identify bottlenecks, waste, and inefficiencies, and develop strategies to improve the process.

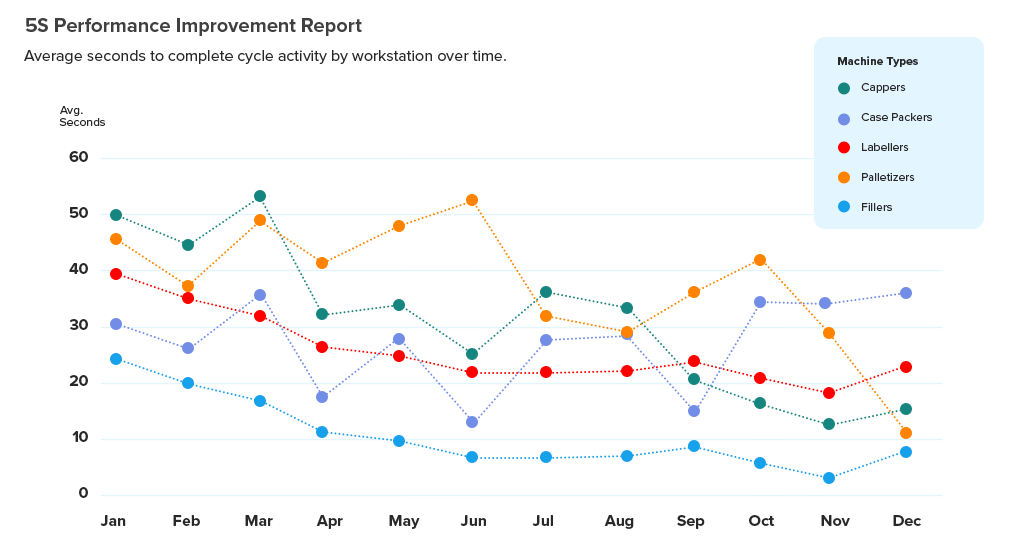

Cycle-based activity timing involves timing operators while they perform a cycle-based activity, such as palletizing one pallet of product, capping one case of product, packing one case of product, labeling one case of product, or filling one case of product.

How does it work?

CI managers work with operators to choose an activity that is consistent over time for each workstation. The average time for each activity is charted over time. If the 5S initiative is working, cycle times will decrease, and OEE will increase.

Measuring cycle time can be used to improve manufacturing processes by reducing setup time, improving flow, and increasing throughput.

Moreover, this practice offers strategic guidance to focus on areas that yield the most results. For instance, CI managers may discover that capper machine workstations are lagging behind the other groups, indicating a need to review the 5S and talk to operators about how to improve workstations.

How can Weever help?

Weever includes a cycle-time stopwatch feature and a Performance Improvement Report so you can begin this process ASAP with our platform. Feel free to learn more about how Weever solves 5S audits.

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo