Best Practices for creating a 5S Audit Checklist

7 Tips to ensure successful 5S Audits

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

5S Overview

5S is a workplace organization methodology that uses a list of five Japanese words:

seiri (整理) = sort

seiton (整頓) = set in order

seisō (清掃) = shine

seiketsu (清潔) = standardize

shitsuke (躾) = sustain

5S is a framework that helps workers organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new organizational system.

The decision-making process usually comes from discussions about standardization, a cornerstone of lean, which builds understanding among employees of how they should do the work.

The steps involve the worker going through everything in a space, deciding what's necessary and what isn't, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

5S Auditing Best Practices

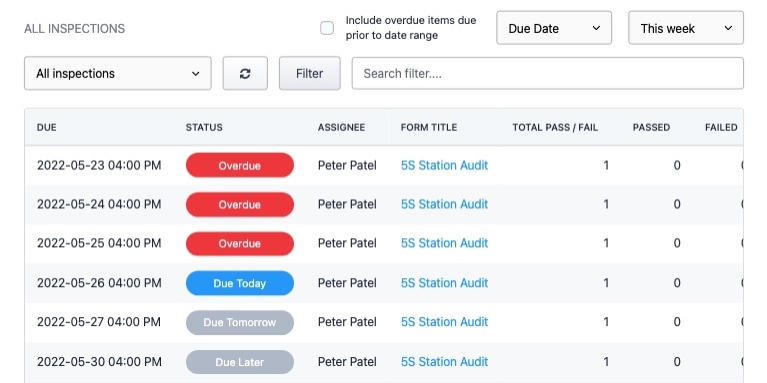

Schedule Audits

Once the workstation is optimized, the best practice is to schedule audits to ensure the workstation continues to be kept in optimal conditions. Most of our customers audit each workstation at least once per month.

The purpose of these audits is not to get staff in trouble - they are to provide feedback about the state of a workstation.

Who conducts 5S audits?

Usually a supervisor will assess each operators workstations, however, some customers use peer-to-peer evaluations with supervisor oversight to ensure they are auditing each other correctly.

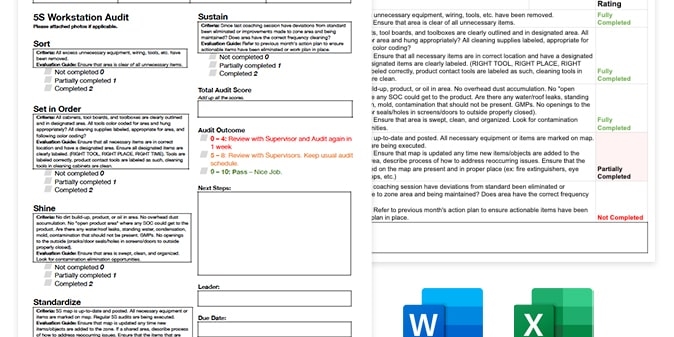

5S Audit Forms (Scorecards)

5S Audit forms (or 5S Audit Sheets) are used to complete the 5S audits. 5S Audit Forms typically include a ranking system that provides feedback to operators and supervisors about the state of each “S” and suggestions as to how to correct any issues. Scores are usually from 1 to 3:

1 = Not completed

2 = Partially completed

3 = Completed

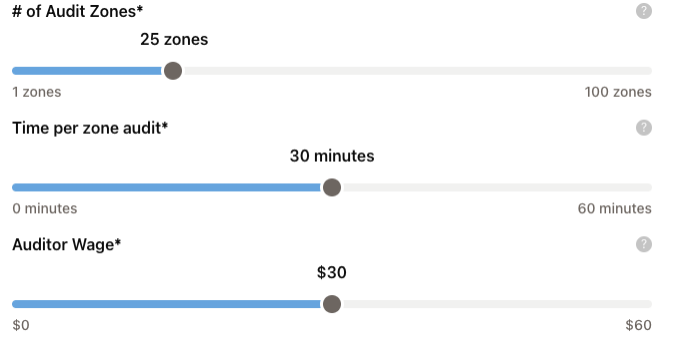

There are several free 5S Checklist Templates on the internet that you can use to move forward. Paper forms are a great place to start but there are inherent limitations to paper and excel processes that you may encounter.

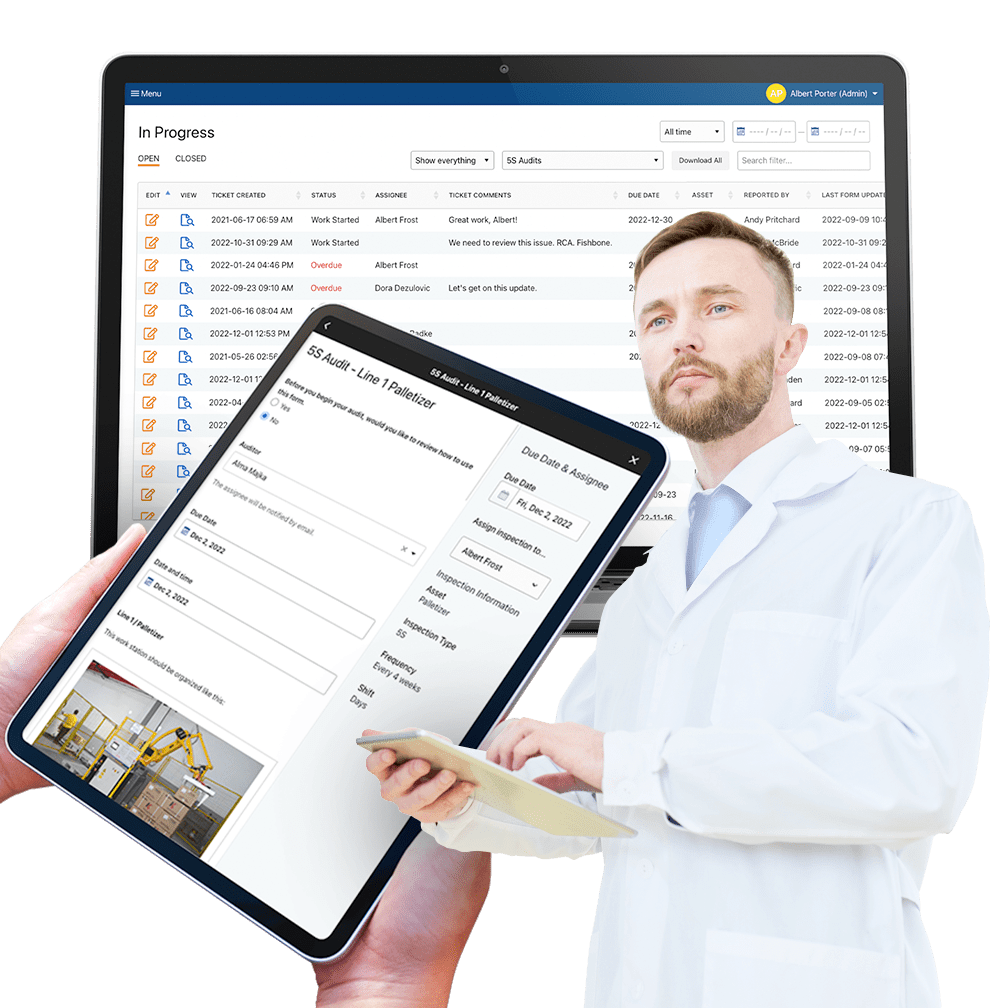

Also, there are many benefits to digitizing a 5S auditing process.

One benefit of a digital 5S audit form is capturing photos to provide more information and context for your feedback. You can also use conditional logic to request additional information only if an S fails inspection.

Digitized 5S processes also more accessible to staff who can use their own phone (BYOD) or use the tablet on the line.

Comparing to Original Photo

The original 5S process is completed when staff arrive at an optimal state for the workstation. The point of the audit is to rate the current state of each S as compared to the optimal state. As a result, photos of the optimal state can be very helpful.

With a digital solution, you can simply add the photos to the form so they are available for reference each and every time.

The 30-second rule

The “30-second” rule is a simple exercise that allows managers to access and compare optimization between workstations. The idea is simple - simply measure how long it takes for an operator to find a tool. If they find the tool within 30 seconds then it is registered as a pass. If they do not, it is registered as a failure. This video provides a great quick overview of the process. This serves as a good KPI for the success of 5S across all workstations in your facility.

Total 5S Audit Score

To find the total 5S audit score, simply divide sum of the audit by 5, the number of “S” standards being evaluated. For example, if you scored each “S” a 3 (perfect score), the total score of the audit will be 3 ((3+3+3+3+3) / 5).

5S Audit Reporting

Good 5S Audit Reporting provides insights into performance broken down by workstation, staff members, lines, and the “5S” framework itself so that Continuous Improvement managers can retrain on specific items. Radar charts are invaluable to understand what is underperforming so that trainers can create programs and improve performance in certain areas.

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo