What software can do for you to enable 5S Auditing

The role digitization plays in the enhancing the efficiency of sustaining your 5S gains.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Maximizing Efficiency: The Power of Software in 5S Auditing

In the ever-evolving landscape of manufacturing, efficiency is the cornerstone of success. One proven method that has stood the test of time in promoting efficiency and organization is the 5S methodology. Originating from Japan, the 5S framework—Sort, Set in order, Shine, Standardize, and Sustain—provides a systematic approach to workplace organization and cleanliness.

Integral to the longevity and success of the 5S methodology is the implementation of a regular auditing schedule. 5S audits help organizations ensure that the principles and standards of 5S are consistently applied, leading to sustained improvements in productivity, safety, engagement, and overall work environment.

However, the traditional approach to 5S audits, often reliant on paper-based systems and manual tracking for data capture and reporting, can be time-consuming and prone to errors. Enter the era of digitization, where software solutions play a pivotal role in enhancing the efficiency of sustaining 5S gains.

What is the 5S "Normalizing" Phase?

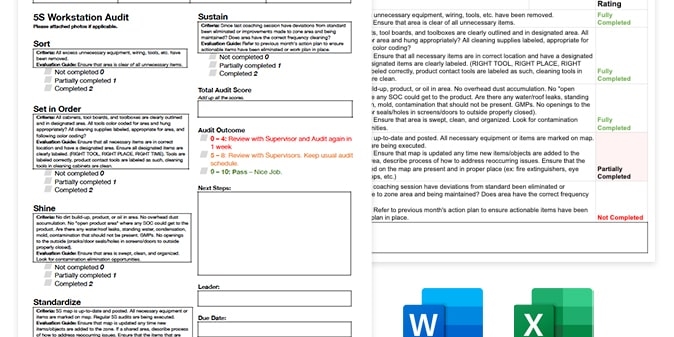

5S auditing is a structured and systematic approach to workplace organization and cleanliness, designed to improve efficiency, safety, and overall productivity within a manufacturing or operational setting.

Standardize and sustain are the final two steps in the 5S methodology and play a pivotal role in ensuring the lasting success of the implemented changes. Part of what we refer to as the "Normalize" phase, Standardize and Sustain are implemented after the original "Optimization" phase to ensure 5S efficiency gains are not lost moving forward.

Standardization involves creating and adhering to a set of guidelines, checklists, and protocols that ensure consistency in the application of the first three S's across the entire organization. This step establishes a uniform approach to organization and cleanliness, reducing variability and promoting a standardized work environment.

Sustain is perhaps the most critical element, focusing on creating a culture of continuous improvement. It involves the ongoing commitment to maintaining the established standards and encouraging a proactive mindset among employees.

Sustainment ensures that the principles of 5S become ingrained in the organizational culture, transforming them from a one-time initiative into a sustainable and habitual way of working. Together, standardize and sustain form the foundation for a workplace that not only achieves 5S goals but sustains them for long-term operational excellence.

Interested in learning more about Weever?

The Role of Software in 5S Auditing: A Digital Revolution

In the fast-paced world of manufacturing, where every second counts, the integration of software in 5S auditing is not just a technological upgrade; it's a strategic imperative. The benefits of real-time visibility, standardized processes, comprehensive data analysis, enhanced collaboration, and increased accountability are indispensable in sustaining the gains achieved through the 5S methodology.

As manufacturing organizations continue to seek ways to optimize their operations, embracing the digital future of 5S auditing is a step towards not just efficiency, but excellence. The power of software is not just in its ability to streamline processes but in its capacity to transform the very nature of how organizations approach and sustain improvement initiatives. Embrace the digital revolution, and watch as your 5S gains reach new heights of efficiency and excellence.

Embracing digitization in 5S auditing can revolutionize the way organizations uphold the principles of the 5S methodology. Let's delve into the core ways in which software can benefit manufacturing organizations:

1. Real-Time Visibility and Accessibility

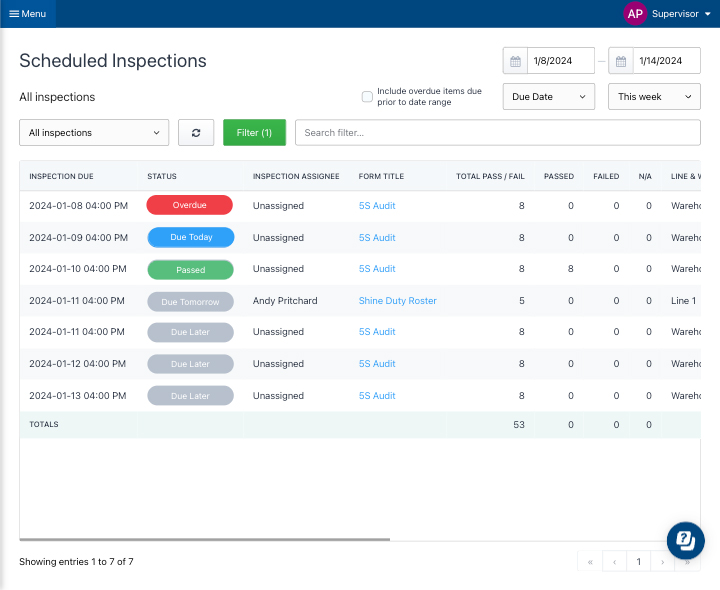

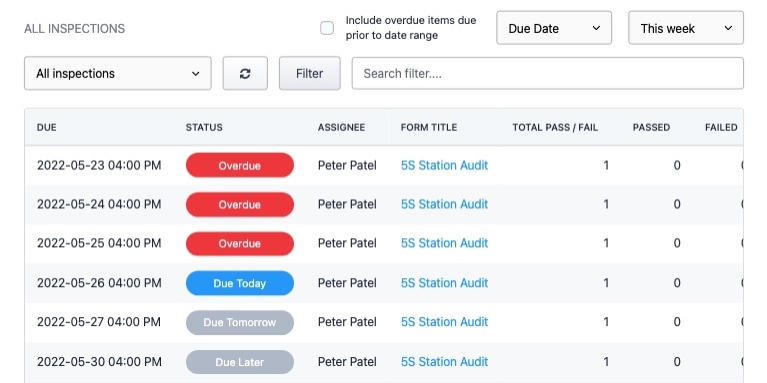

One of the primary advantages of 5S audit software is the ability to provide real-time visibility into the audit process.

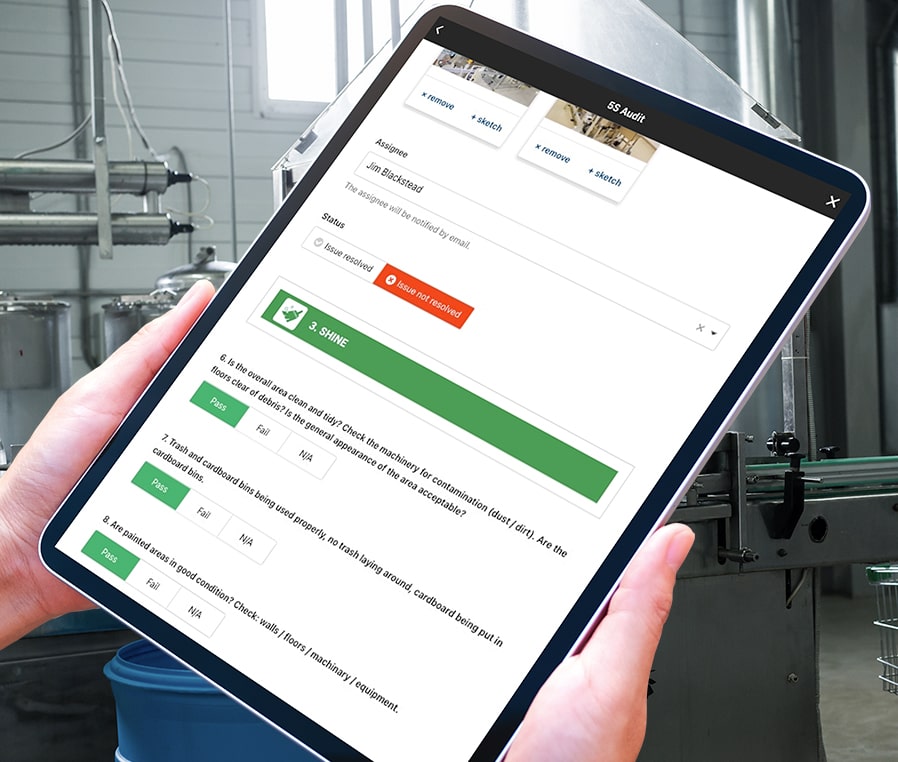

Digitized systems allow auditors to input data directly from the shop floor, eliminating the lag time associated with manual data entry.

This real-time accessibility enhances the accuracy and timeliness of audit information, enabling quick corrective actions and fostering a proactive approach to continuous improvement.

2. Standardization of Audit Processes

5S audit software facilitates the standardization of audit processes across different areas of the organization.

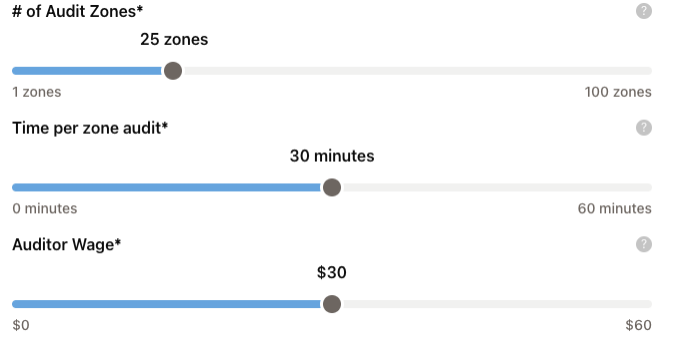

Through customizable digital checklist forms, organizations can ensure that audits are conducted consistently, following predefined criteria. This standardization not only streamlines the auditing process but also establishes a baseline for comparison and benchmarking over time.

Learn more about Digital Auditing Checklist Best Practices ⇒

3. Comprehensive Data Analysis

Software solutions enable the collection and analysis of vast amounts of rich data generated during 5S audits.

By leveraging analytics tools, organizations can gain valuable insights into trends, identify recurring issues, and make data-driven decisions to optimize their 5S initiatives.

This level of comprehensive analysis goes beyond the capabilities of manual audits, providing a holistic view of the organization's adherence to 5S principles.

4. Enhanced Collaboration and Communication

Digitized 5S audits foster improved collaboration and communication among team members.

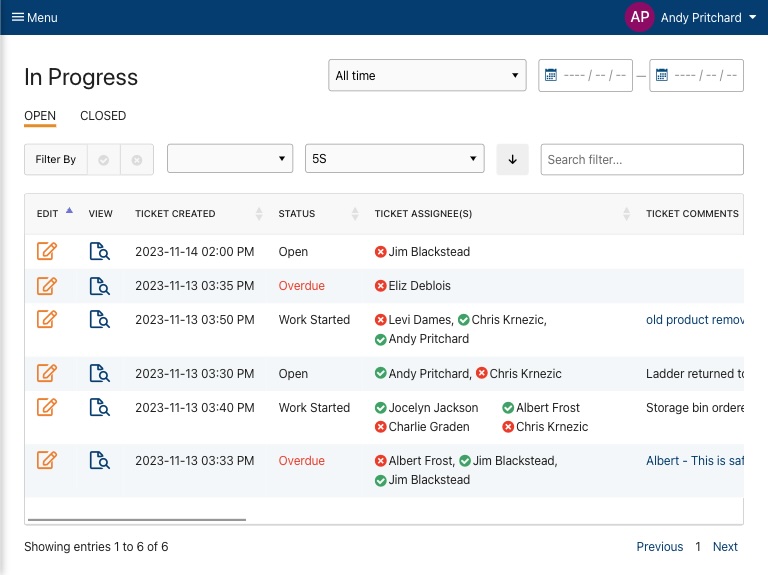

With centralized databases and communication channels, stakeholders can easily share audit results, track progress, and collaborate on corrective actions.

This interconnected approach enhances teamwork and ensures that everyone is aligned towards the common goal of sustaining 5S gains.

5. Increased Accountability and Traceability

Accountability is a key factor in the success of any organizational initiative. 5S audit software allows for the establishment of clear accountability structures by assigning tasks and responsibilities directly within the digital platform.

This not only increases accountability but also provides traceability, allowing organizations to track the progression of corrective actions and monitor the impact on overall 5S compliance.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo