Business Solutions Lead

How elevated safety increases employee engagement at manufacturing organizations

Elevated safety can have a positive impact on employee engagement at manufacturing organizations by building trust, boosting morale, reducing stress, increasing productivity, and improving retention.

Read MoreHow does workflow automation increase collaboration in a manufacturing facility?

Workflow automation can increase collaboration in a manufacturing facility in several ways. By automating the flow of information between different systems and teams, manufacturers can improve communication and collaboration, leading to better decision-making and more efficient operations.

Read MoreHow does workflow automation reduce costs for manufacturing organizations?

Workflow automation can help manufacturing organizations reduce costs by eliminating waste, reducing errors, and improving efficiency. By automating routine tasks, manufacturers can save time and reduce the cost of labor-intensive manual processes.

Read MoreHow does workflow automation help to reduce errors for operators at a manufacturing facility?

Workflow automation can help reduce errors for operators at a manufacturing facility in several ways. Automation ensures tasks are completed correctly every time, which reduces rework, defects and time-to-close maintenance tickets.

Read MoreAutomate mundane, manual processes to increase productivity

The elimination of manual processes through automation can significantly increase productivity for manufacturers by reducing the time and resources required to complete tasks. Here are some of the key ways that automation can improve productivity.

Read MoreEnhance Productivity through Automation

In today’s fast-paced business environment, manufacturing organizations are under constant pressure to increase productivity and reduce costs.

Read MoreTop 5 Benefits of digitizing food plant sanitation schedules

There are many advantages to digitizing your sanitation schedule, including improved efficiency, increased accuracy and consistency, improved compliance, reduced costs and risks and improved data management.

Read MoreMark’s, Canadian Tire, SportChek solves vendor non-compliance with Weever.

We needed a way to document non compliant shipments sent to us from our vendors in a way the clearly demonstrated the errors to the vendors. Additionally, we needed to capture this evidence from multiple locations with distribution to specific downstream teams (including the ability to have a file format that can be saved on an SFTP0 based on the location that identified the non compliance.

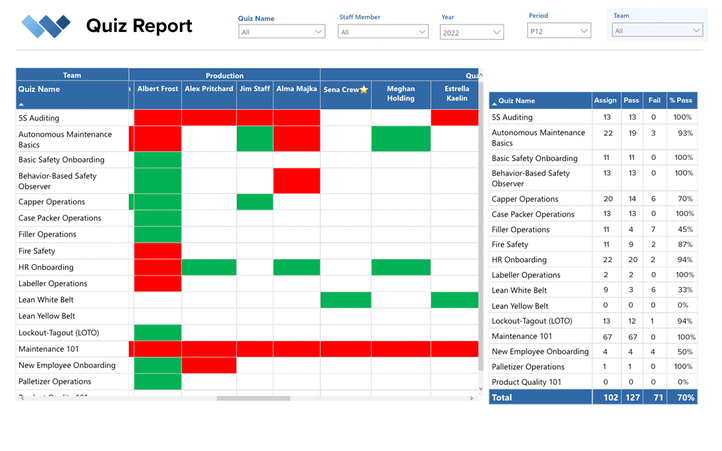

Read MoreEmployee Quiz Report

Frontline Worker Quiz Report live demo. Understand instantly the training status of your workers, including who is assigned training and who has passed.

Read MoreBuild a Culture of Excellence through Human Insights

Cultural challenges can be at the root of every issue that your organization encounters, including productivity, safety, quality, maintenance, human resources, and financial performance because it is the foundation on which everything else sits.

Read More