How does workflow automation help to reduce errors for operators at a manufacturing facility?

Workflow automation can help reduce errors for operators at a manufacturing facility in several ways:

1. Standardized Processes

Automated workflows can be designed to standardize processes across the manufacturing facility, reducing the risk of human error. By using pre-determined rules and workflows, operators can ensure that tasks are performed consistently and accurately.

2. Elimination of Manual Data Entry

Manual data entry is one of the most common sources of errors in a manufacturing facility. Automating data entry tasks can significantly reduce errors by eliminating the need for operators to manually enter data. Automated systems can import data directly from machines or sensors, reducing the risk of transcription errors.

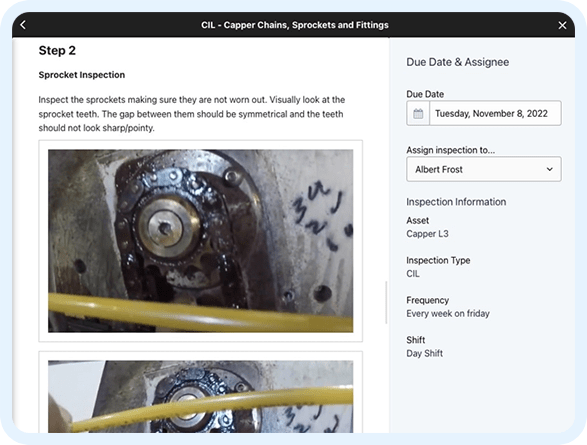

3. Reduced Complexity

Automation can simplify complex workflows, making them easier for operators to understand and complete. By breaking down complex processes into smaller, more manageable tasks, operators can focus on completing each step accurately, reducing the risk of errors.

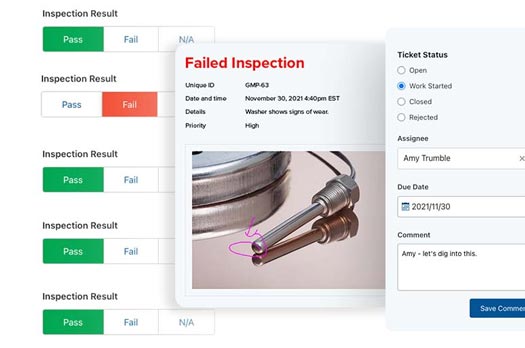

4. Real-time Monitoring

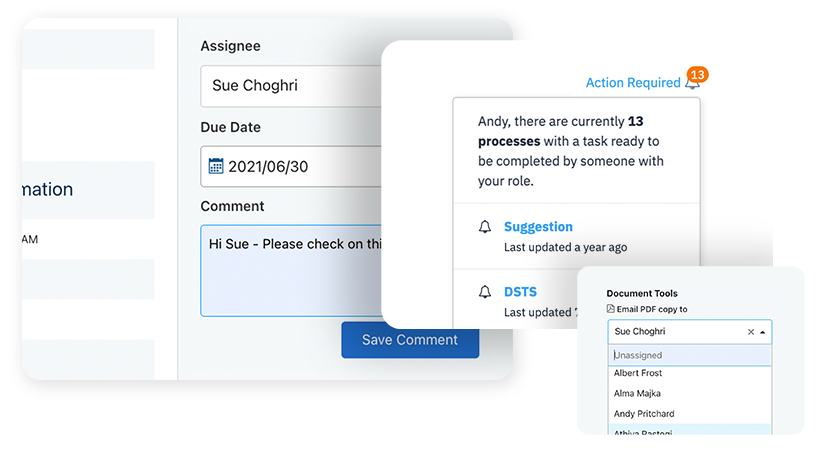

Automated workflows can be designed to monitor processes in real-time, alerting operators when an error occurs. This can help operators quickly identify and correct errors before they cause significant problems.

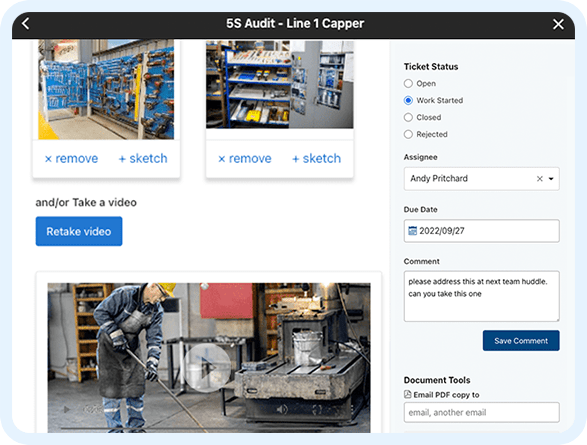

5. Improved Collaboration

Automated workflows can also improve collaboration among operators by providing a centralized system for tracking and managing tasks. This can help operators share information and communicate more effectively, reducing the risk of miscommunication and errors.

6. Data Analytics

Workflow automation systems can generate reports and analytics that can help operators identify areas of the manufacturing process that are prone to errors. This information can be used to improve processes, reducing the risk of future errors.

How can Weever help?

In summary, workflow automation can help reduce errors for operators at a manufacturing facility by standardizing processes, eliminating manual data entry, simplifying complex workflows, providing real-time monitoring, improving collaboration, and using data analytics to identify areas of improvement. By reducing errors, workflow automation can help manufacturers improve product quality, reduce waste, and improve overall efficiency.

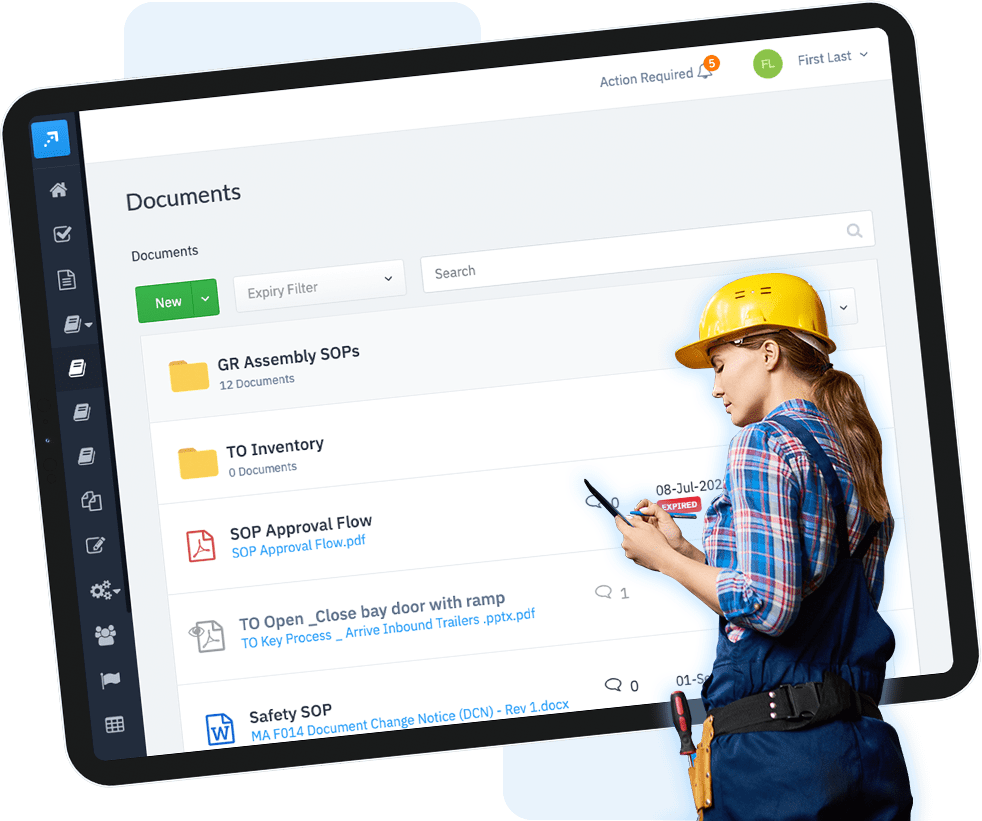

Weever saves time and money through powerful workflow automation, which enhances productivity in every department throughout your organization. By automating mundane and repeatable administrative tasks, Weever dramatically enhances productivity and gives time back to your leadership, which can be reallocated towards more value add activities.

SCHEDULE A DEMO

Take a Guided Tour.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.

Monin was drowning in paper and looking for a system that would ensure compliant workflows and automate KPI reporting insights to inform continuous process improvement, all without overwhelming operators.

Learn about the Platform.

Download the brochure to get all the details about how Weever works.

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware