Business Solutions Lead

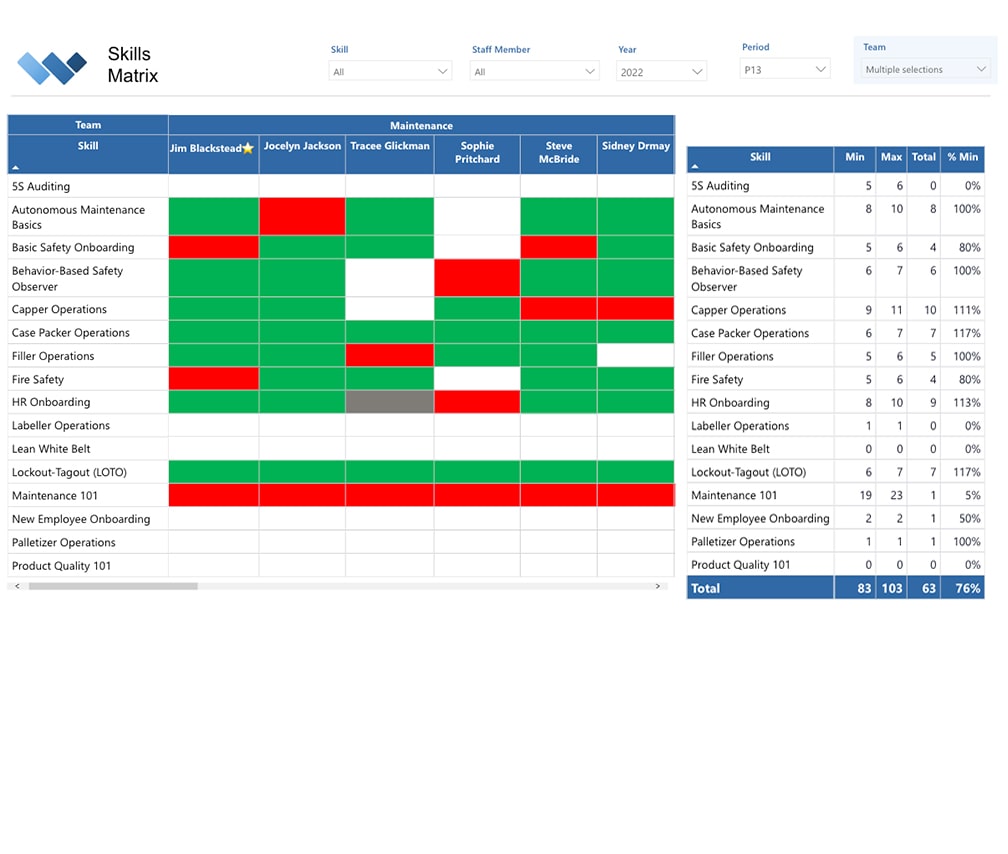

Skills Matrix Dashboard

What is the competency level of staff by shift, line, etc? Where are my critical gaps?

Read MoreSkills Matrix

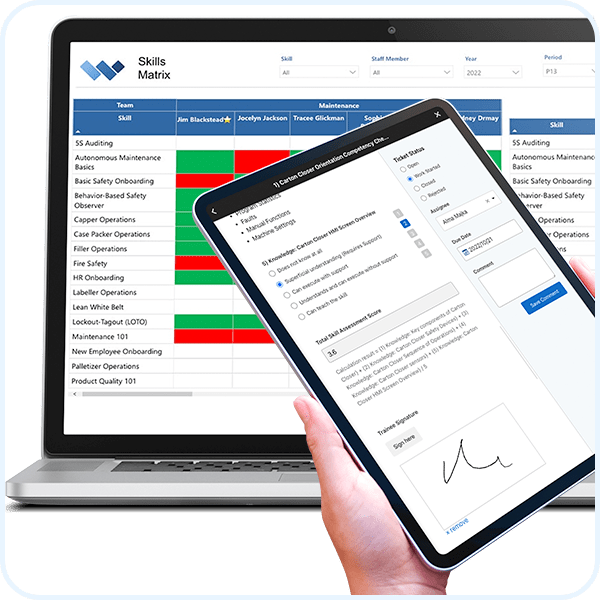

Easily perform competency checks and understand skills and gaps instantly.

Read MoreMaster Batch Records

Ensure compliance and enhance efficiency. Guide staff through the process to ensure compliance.

Read MoreWhat are the types of abnormality categories and why should I use them?

How to use standard abnormality report categories and subcategories to create insight-driven reporting. Here are the recommended categories and subcategories as well as some helpful considerations for your frontline staff to aid next steps.

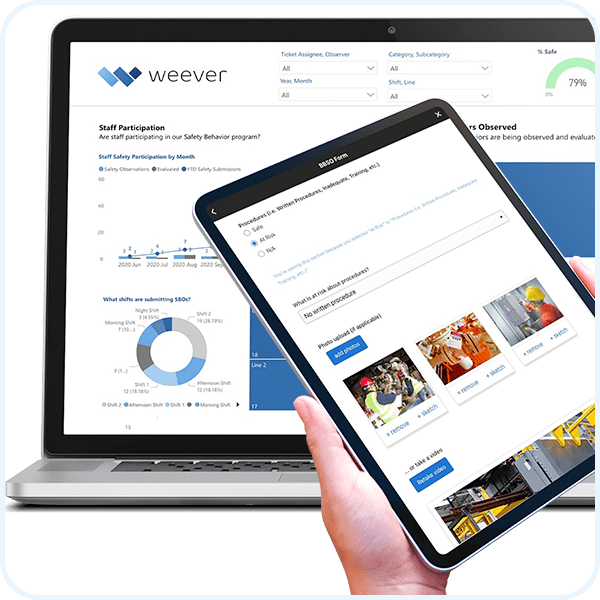

Read MoreBehavior-Based Safety Overview

Over 90% of workplace incidents are caused by unsafe behaviors, not conditions.

As a result, reducing at-risk behaviors will have the greatest impact on incident frequency and severity.

Behavior-Based Safety Observation (BBSO) programs are the most turnkey and effective way to build better safety practices.

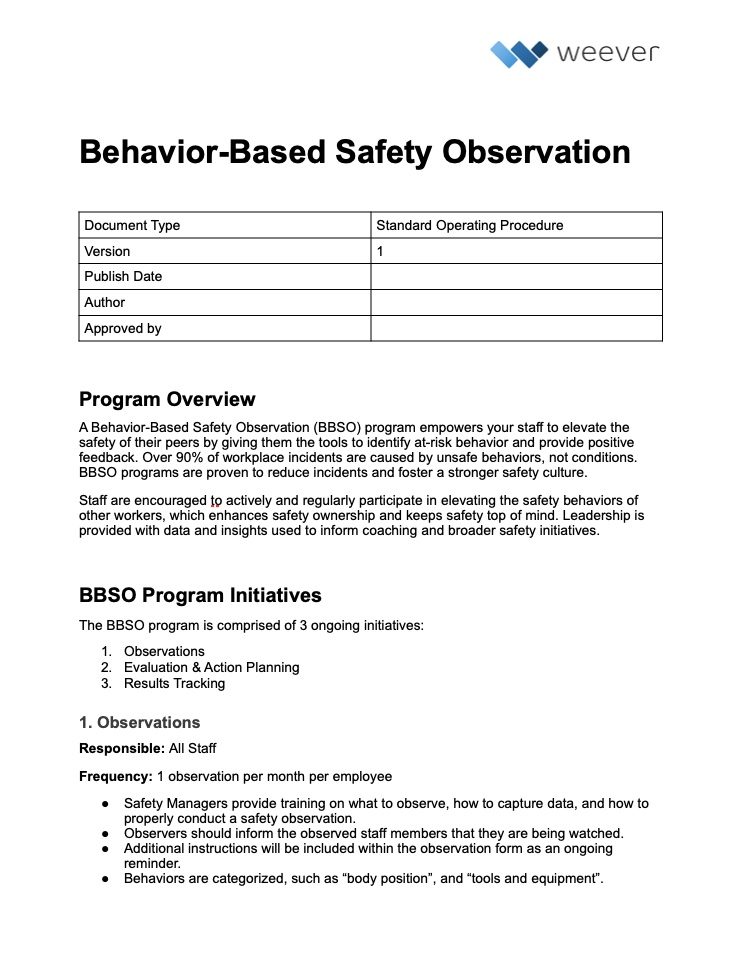

Behavior-Based Safety (BBSO) Standard Operating Procedure (SOP) MS Word .doc Template

Download a free Standard Operating Procedure (SOP) word doc template you can adapt to build your Behavior-Based Safety Observation (BBSO) program.

Read MoreEpisode 5: Eliminate Admin Time and Automate Tracking With Digital BBSOs with Steve McBride, CEO & Founder of Weever

In this episode of Digitization Mavericks, we are joined by Steve McBride, Weever’s very own CEO and Founder. Steve is a manufacturing veteran with more than 30 years of industry experience and has worked with manufacturers across every industry.

Read MoreBetter Continuous Improvement Data through Digital Transformation

Juan is a process engineer with a decade of experience helping CPG manufacturers implement continuous improvement processes. In his latest role he found himself working at a small division of a large national food manufacturer that was just taking its first steps towards lean manufacturing and operational excellence.

Read MoreMonin saves 3-4 hours each day with Weever

Monin was drowning in paper and looking for a system that would ensure compliant workflows and automate KPI reporting insights to inform continuous process improvement, all without overwhelming operators.

Read MoreFiix CEO James Novak named to Weever’s board of directors

James Novak, Former CEO of Fiix Inc., has been named to the board of directors at Weever, the leading cloud-based pioneer in the fast-growing Manufacturing Operations Digitization space.

Read More