Maintenance Management

How to remove wasted administration time from your audits

How to remove wasted administration time from your auditing process Andy Pritchard | March 23, 2022 | 5 min read Audits are usually required by law, can include layers of complexity and stiff fines if completed incorrectly. Digitization helps to elevate engagement, simplify administration and ensure compliance requirements are met. How do Audits work? Audits…

Read MoreWhat are F-tags and why digitize them?

What are F-tags and why digitize them? Andy Pritchard | March 17, 2022 | 4 min read F-tag is a visual work order system where staff apply paper tags to machines when a process abnormality is observed. “F” stands for Fuguai, which is Japanese word that means “deviation” or “abnormality”. F-tags can be for…

Read MoreWhy use software to manage Work Permits?

Why use software to manage Work Permits? Steve McBride | Jan 8, 2022 | 6 min read The Permit To Work system (PTWs) authorizes, approves and manages the workflow of non-standardized construction, maintenance, inspection or repair activities that pose a potential risk to personnel, damage to equipment or facilities, disruption of operations or…

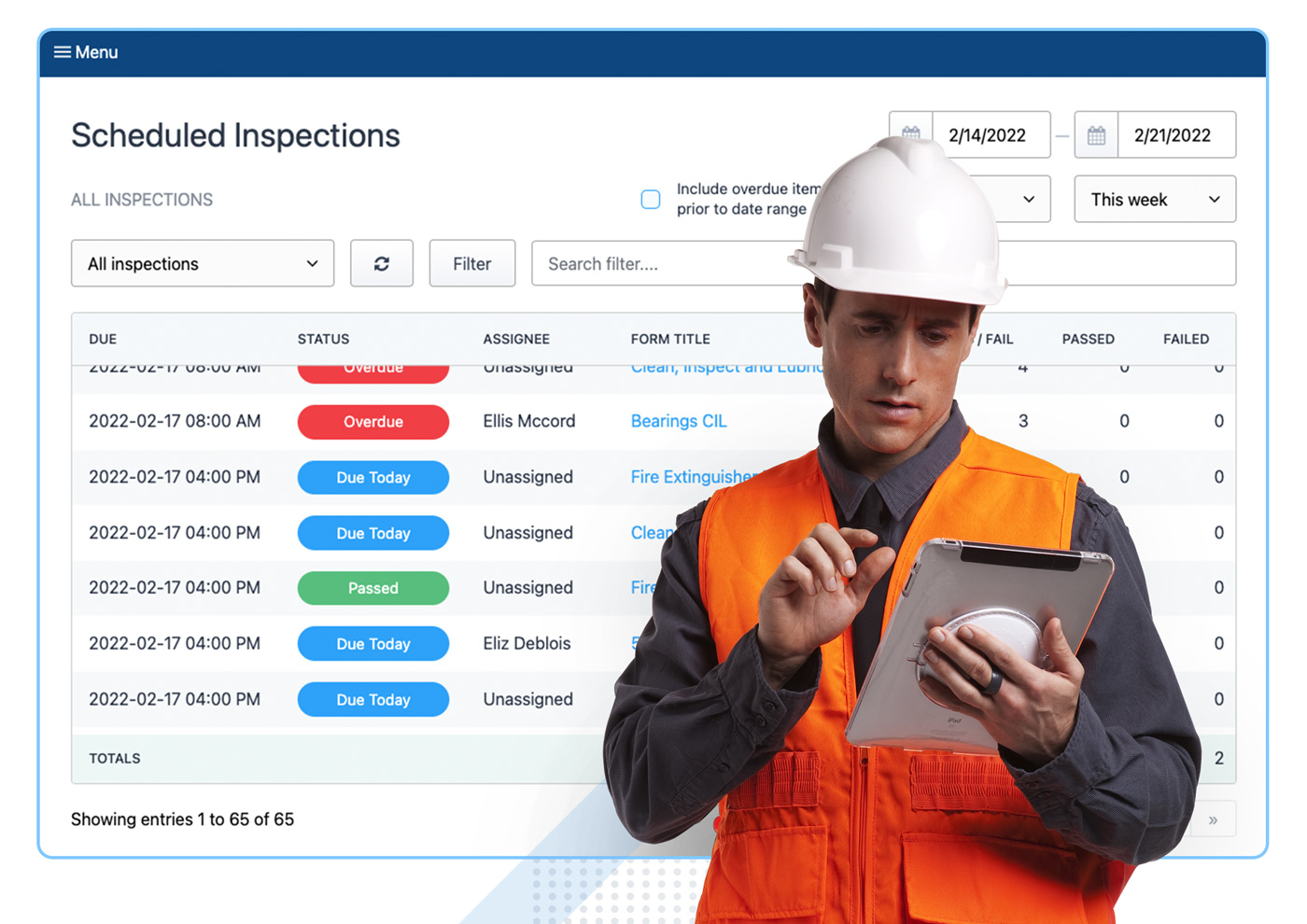

Read MoreWhy are paper forms insufficient for inspection schedules?

Digitizing an inspection schedule takes some effort, so you want to get it right the first time. As you have probably discovered if you’re managing an inspection schedule, paper forms are not ideal for ensuring inspections are completed correctly and on time.

Read MoreWhat are the 7 steps of autonomous maintenance?

Quick overview of the 7 steps of Autonomous Maintenance from Increasing Operator Knowledge to Establishing Continuous Improvement and everything in between.

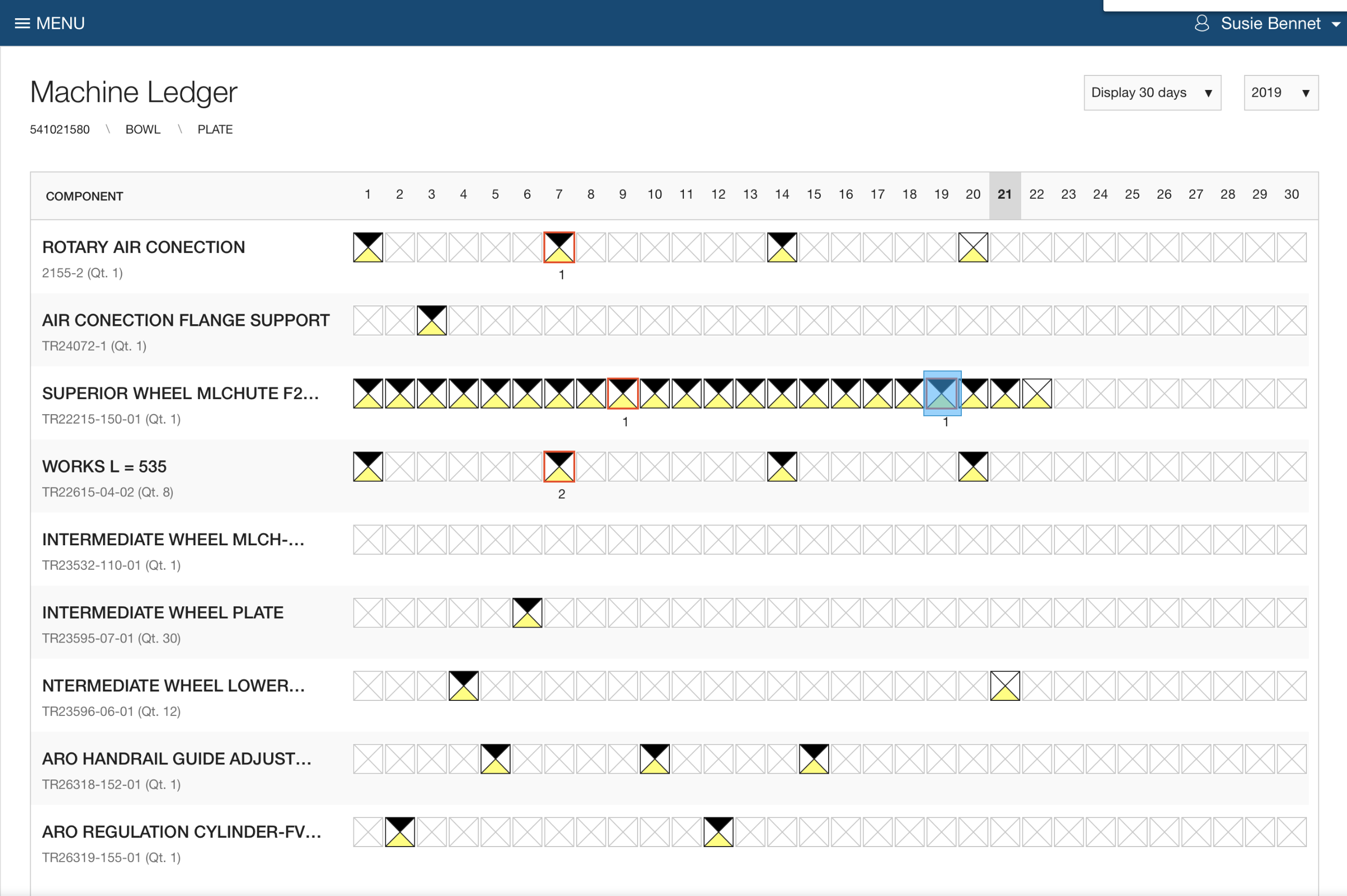

Read MoreUnderstanding the Machine Ledger

The Machine Ledger is used in World Class Manufacturing to better understand machines, sections, assemblies, and components so that maintenance teams can more effectively predict failures and plan preventive maintenance activities.

Read More