Operational Excellence

Transforming Manufacturing with Integrated Work Systems: Benefits and Best Practices

Transforming Manufacturing with Integrated Work Systems: Benefits and Best Practices Transform manufacturing by making Weever part of your integrated work system. Improve communication, reduce errors, and manage resources efficiently. Integrated work systems are a powerful tool in the manufacturing industry, combining various processes, tasks, and technologies into one seamless system. These systems help manufacturers streamline…

Read MoreThe Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency

The Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency Enhance manufacturing with predictive maintenance. Learn how Weever’s software integrates data collection and analysis to not only prevent, but predict equipment failures. Predictive maintenance is a game-changer in the manufacturing industry. Unlike traditional reactive maintenance, which fixes problems after they occur, predictive maintenance anticipates issues…

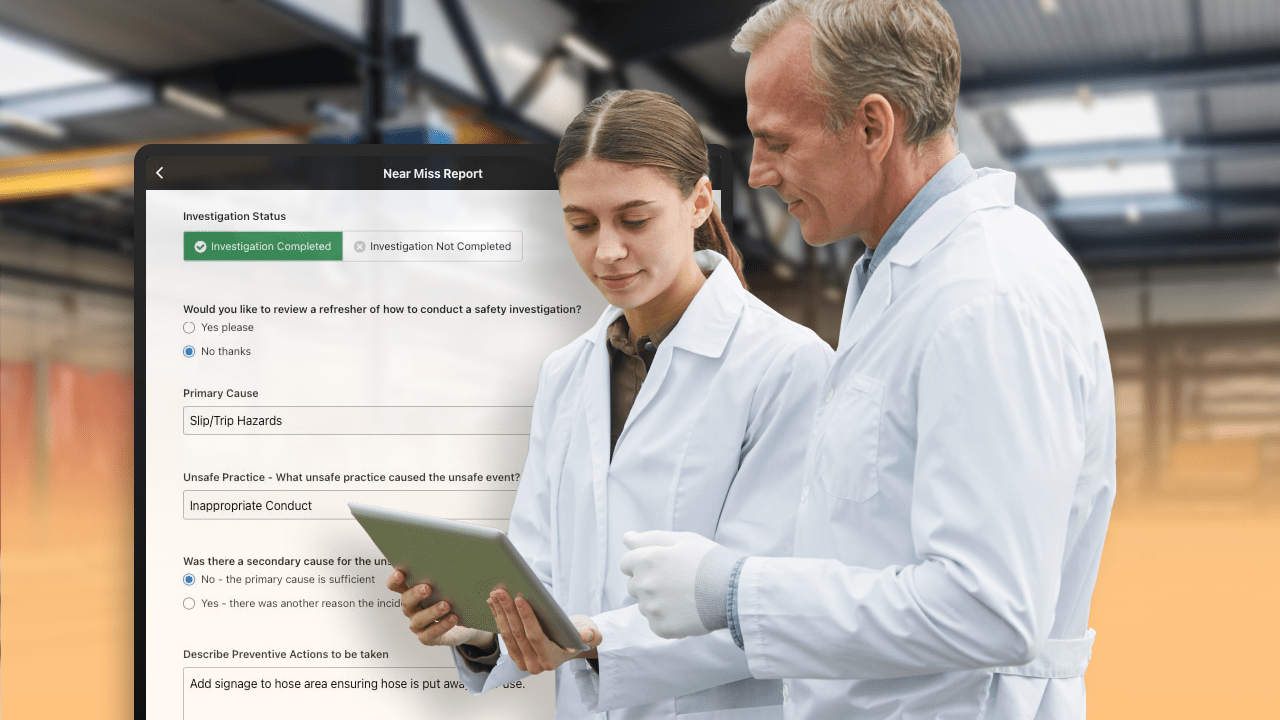

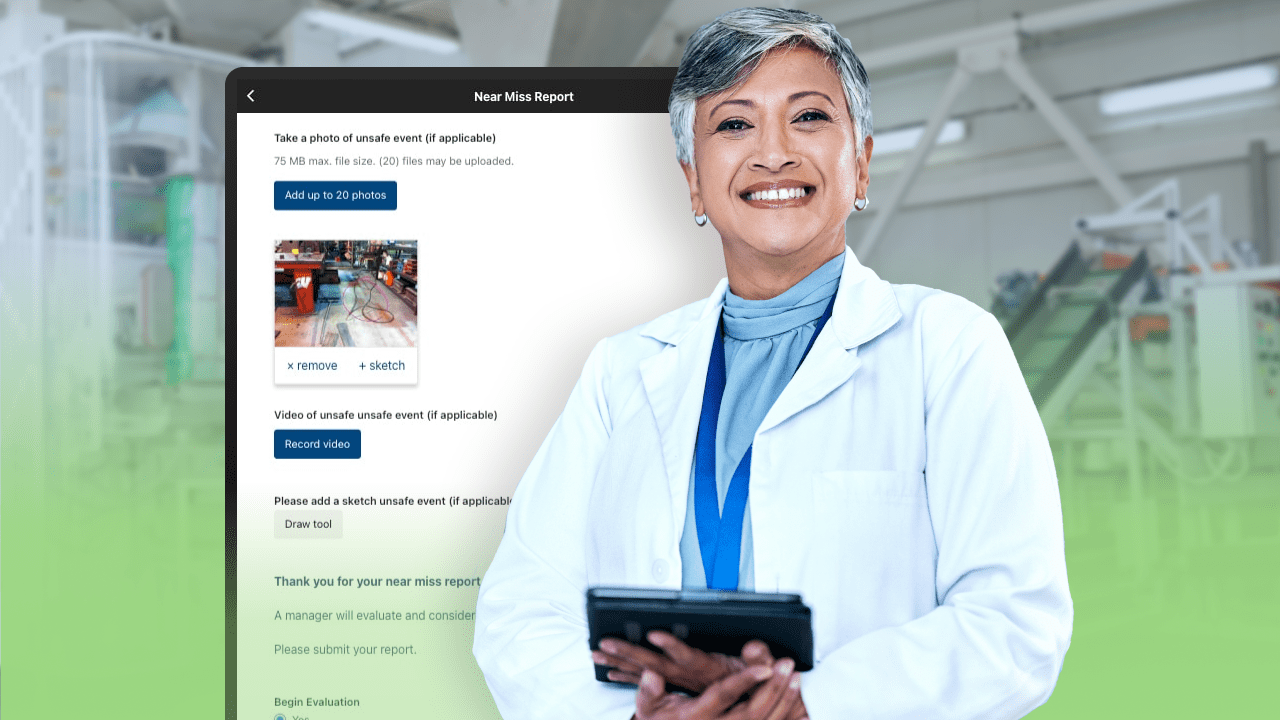

Read MoreHow Near Miss Reporting Software Can Transform Your Manufacturing Safety Culture

How Near Miss Reporting Software Can Transform Your Manufacturing Safety Culture Discover how Weever’s Near Miss Reporting software transforms manufacturing safety with digital data capture, automated tasks, and real-time insights for a proactive safety culture. Safety in manufacturing is crucial for protecting employees and maintaining efficient operations. Weever’s Near Miss Reporting software helps identify and…

Read MoreTop Features in Near Miss Reporting Software for Manufacturing

Top Features in Near Miss Reporting Software for Manufacturing Discover top features in near miss reporting software for manufacturing. Learn how Weever’s solutions improve safety, streamline reporting, and boost efficiency. In manufacturing, near miss reporting software is crucial for preventing accidents and enhancing safety. By capturing and analyzing incidents that almost led to accidents, manufacturers…

Read MoreHow a Configurable Program Template Can Transform Your Manufacturing Operations

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

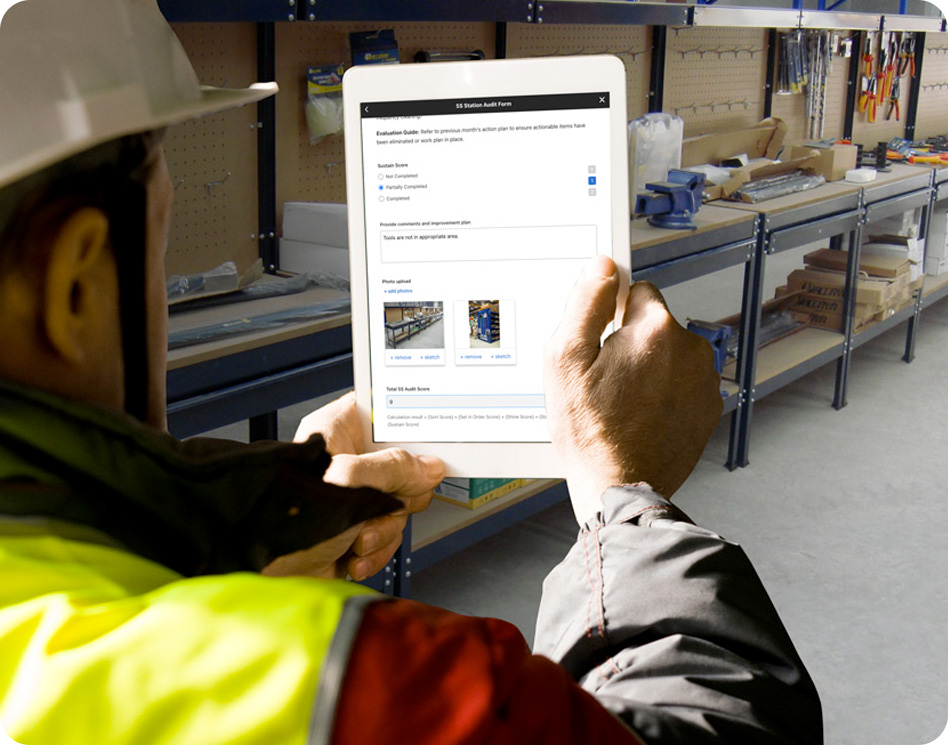

Read MoreHow to gather data to support your 5S business case

To substantiate the case for 5S adoption, gathering benchmark data and evidence-backed KPIs becomes crucial. The right KPIs not only provide quantifiable data but also serve as compelling evidence to support the business case for 5S implementation.

Read MorePain Points Solved with 5S

When planning your 5S implementation, it is important to align the program’s objectives and benefits with the strategic priorities of your organization.

Read MoreTop 5S benefits for manufacturing companies

The 5S methodology can have a significant positive impact on many success factors for your business, including efficiency gains, enhanced safety and quality, improvements to employee engagement and moral, cost savings and continuous improvement.

Read MoreIs 5S right for you?

If you are uncertain whether 5S is right for your facility askyourself and your team the following questions.If the answer was “yes” to one or more of these questionsyou may find 5S to be very beneficial to your organization.

Read MoreTop 5 Frontline Employee Engagement Best Practice

Are you tired of slogging through your workday, feeling unfulfilled and disconnected from your organization? Do you wish you could be part of a culture of excellence that inspires innovation, collaboration, and engagement?

Well, look no further! We have compiled some of the best practices we’ve seen in our 10 years of working with organizations around the world to help you build a culture of engagement and achieve amazing results.

Read More