Operational Excellence

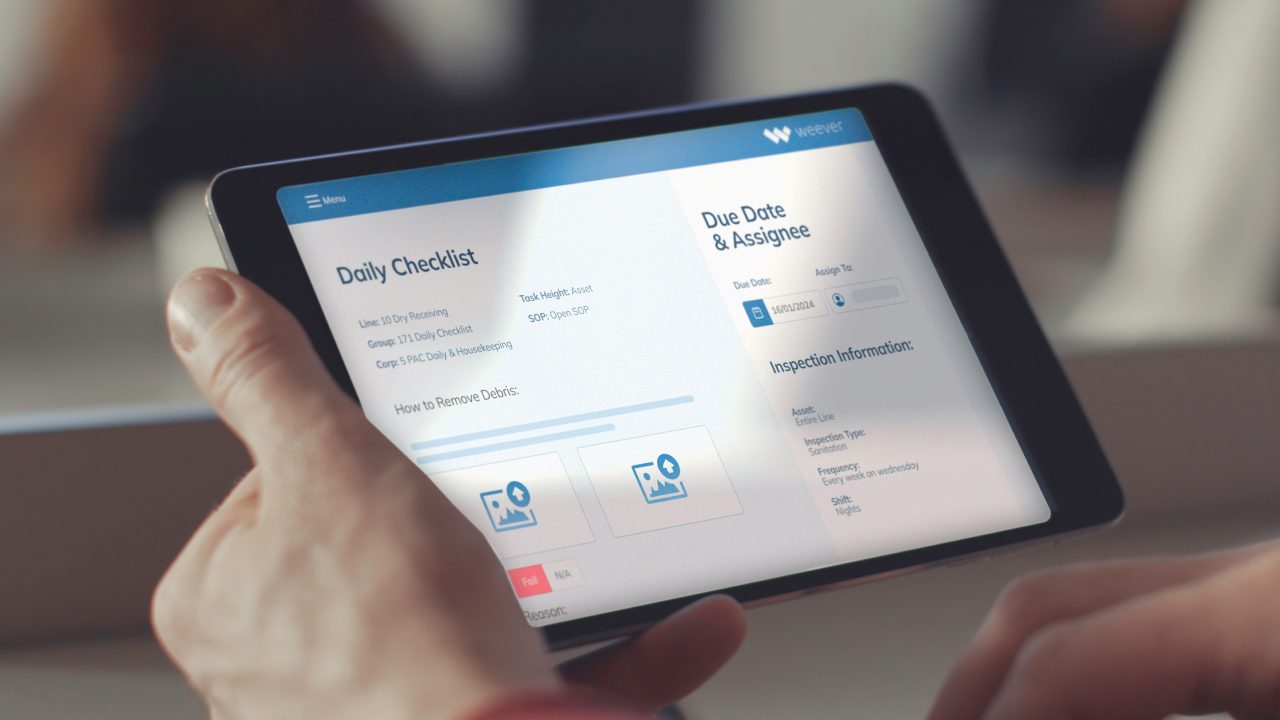

Creating an Effective Manufacturing Audit Checklist with Weever Software

Boost efficiency and productivity in manufacturing operations with Weever Software’s configurable program templates. Learn how to streamline workflows and enhance performance.

Read MoreThe Power of Program Templates in Manufacturing Operations: A Comprehensive Guide with Weever Software

Boost efficiency and productivity in manufacturing operations with Weever Software’s configurable program templates. Learn how to streamline workflows and enhance performance.

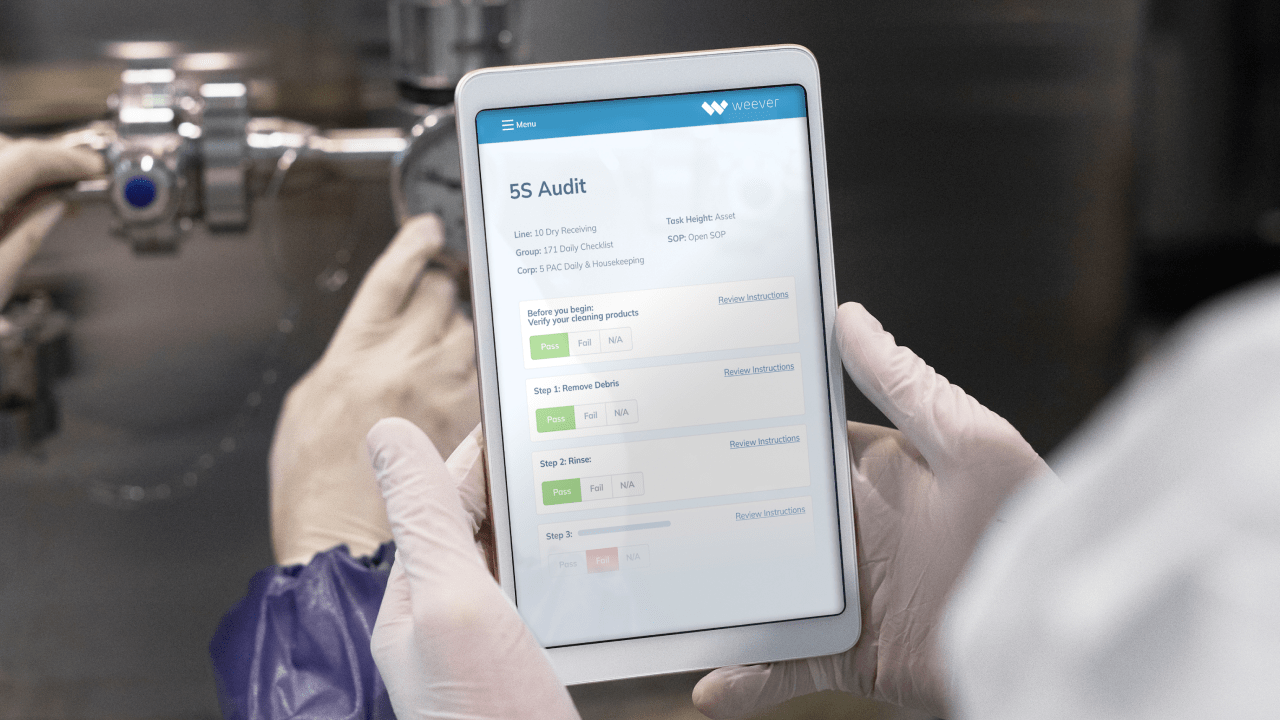

Read MoreThe Benefits of Standardized Program Templates in Manufacturing

The Benefits of Standardized Program Templates in Manufacturing Standardized program templates streamline manufacturing, enhance efficiency, and ensure consistency. Learn how Weever Software simplifies implementation with user-friendly, automated solutions. Efficiency and consistency are key to maintaining a competitive edge in manufacturing. The implementation of new programs and policies can often be a daunting task, requiring significant…

Read MoreThe Role of Observation Forms in Enhancing Manufacturing Safety

The Role of Observation Forms in Enhancing Manufacturing Safety Discover how Weever Software enhances manufacturing safety with digital observation forms, real-time reporting, and automated workflows for timely risk management. In manufacturing, ensuring a safe work environment by identifying and mitigating potential hazards and risks is critical. Observation forms are essential in this process, providing a…

Read MoreTop Features to Look for in Near Miss Reporting Software for Manufacturers

Top Features to Look for in Near Miss Reporting Software for Manufacturers Discover top features in near miss reporting software for manufacturers. Enhance safety, reduce downtime, and improve efficiency with Weever’s solution. Near miss reporting software plays a crucial role in manufacturing by identifying potential hazards before they lead to accidents. This proactive approach not…

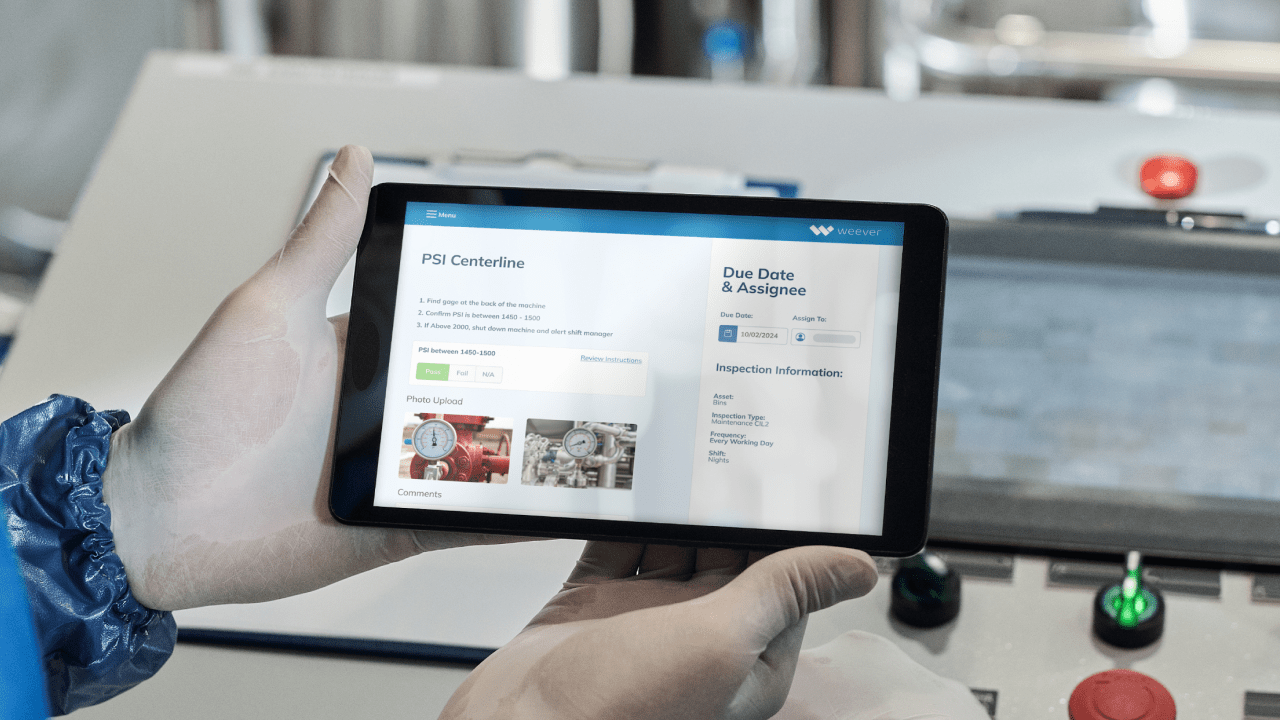

Read MoreTop Benefits of Implementing Predictive Maintenance in Manufacturing

Top Benefits of Implementing Predictive Maintenance in Manufacturing Enhance manufacturing operations with Weever’s predictive maintenance software. Reduce downtime, increase equipment lifespan, and improve safety and compliance. Predictive maintenance is a modern approach to maintaining manufacturing equipment. Instead of waiting for machines to break down, predictive maintenance uses data and analytics to predict when maintenance is…

Read MoreTop 5 Features to Look for in Integrated Work Systems for Manufacturing

Top 5 Features to Look for in Integrated Work Systems for Manufacturing Integrated work systems streamline manufacturing processes, improving productivity and compliance. Discover the top features and see how Weever’s solutions can transform your operations. The modern manufacturing landscape is a complex web of interconnected processes. While each cog plays a vital role, even a…

Read MoreHow Proactive Measures Enhance Predictive Maintenance Programs

How Proactive Measures Enhance Predictive Maintenance Programs Enhance manufacturing reliability by combining proactive measures with predictive maintenance. Maintaining equipment efficiency and dependability is critical in the manufacturing industry. Predictive maintenance has become a vital strategy, utilizing advanced technologies to anticipate and prevent potential equipment failures in advance. This method depends on ongoing monitoring and analysis…

Read MorePredictive vs. Preventive Maintenance: Which is Better for Manufacturers?

Predictive vs. Preventive Maintenance: Which is Better for Manufacturers? Compare predictive and preventive maintenance for manufacturing efficiency. Effective maintenance strategies are crucial in the manufacturing industry to ensure operational efficiency, minimize downtime, and extend the lifespan of equipment. Effective maintenance involves more than just addressing issues as they arise; it also focuses on proactively avoiding…

Read MoreHow Integrated Work Systems Improve Manufacturing Efficiency

How Integrated Work Systems Improve Manufacturing Efficiency Boost manufacturing efficiency with integrated work systems: streamline workflows, reduce downtime, and enhance productivity. Efficacy is of the utmost importance in the manufacturing industry, which moves like clockwork. In a highly competitive market, every second counts, and the ability to effectively simplify operations, minimize waste, and increase efficiency…

Read More