Operational Excellence

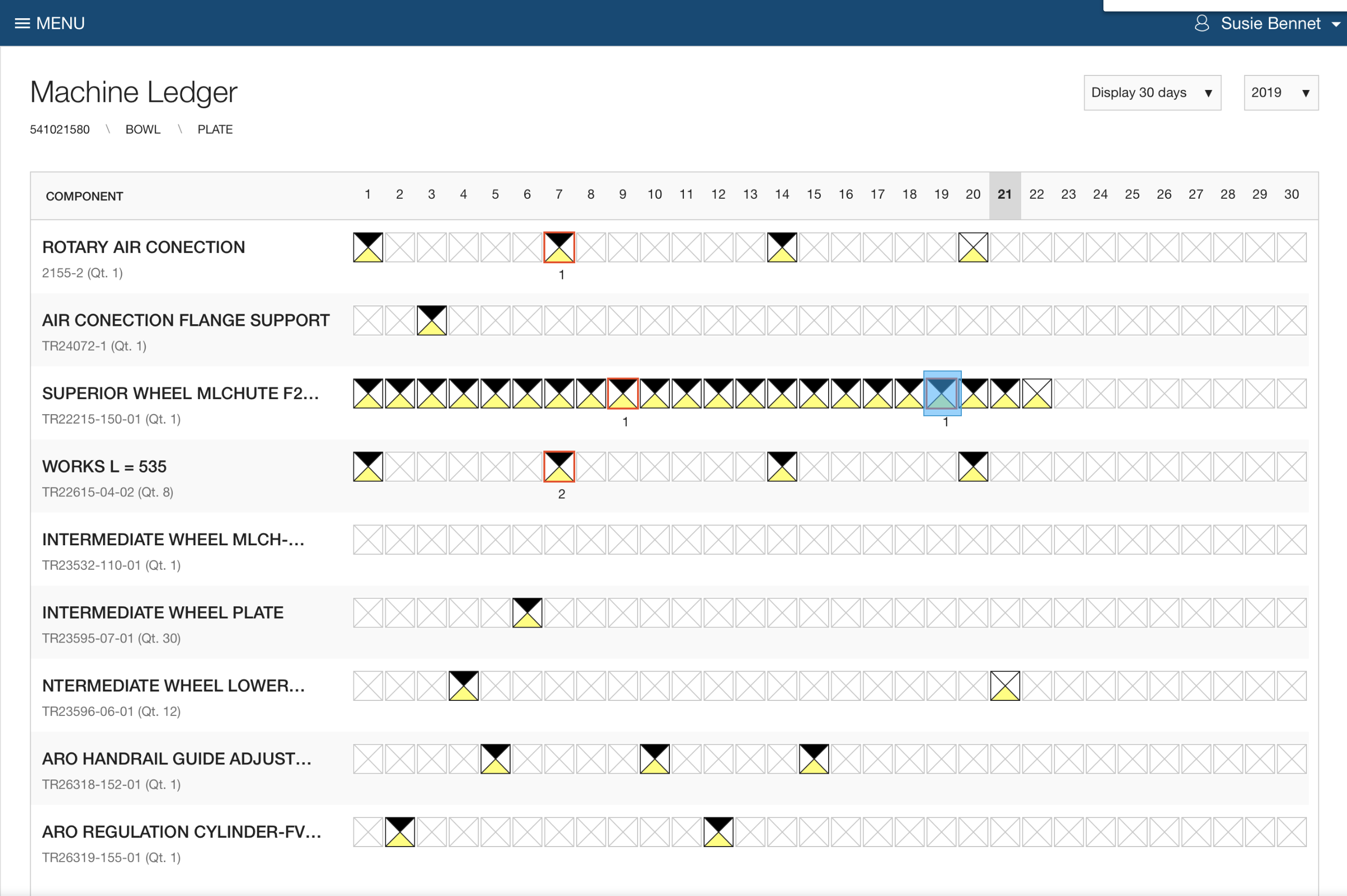

Understanding the Machine Ledger

The Machine Ledger is used in World Class Manufacturing to better understand machines, sections, assemblies, and components so that maintenance teams can more effectively predict failures and plan preventive maintenance activities.

Read MoreWeever wins Innovation Award

Weever Apps is proud to be acknowledged as Frost & Sullivan’s “New Product Innovation Award” winner for the North America Enterprise Mobile Forms market. Weever has been recognized by Frost & Sullivan, a world leader in business research and consulting, as the most innovative new product in the category. According to Frost, Weever received…

Read More4 ways to reduce waste from your Continuous Improvement process

Kaizen is the process of incrementally improving processes by eliminating “waste”. Small improvements over time can have a huge impact on productivity and the bottom line. Waste can come in many forms, including unnecessary inventory, physical movements and scrap. Kaizen only works if everyone is involved, which includes top management and, more importantly, the workers…

Read MoreUSA Food Manufacturing Compliance Requirements

Compliance for manufacturing organizations is comprised of technical, legal and corporate requirements, regulations and practices manufacturers must comply with in order to produce and market products. Numerous areas of compliance can come to bear on manufacturers directly or indirectly, including: Product safety Health, safety, and environmental impact Data protection Export controls Anti-corruption IT safety and…

Read More5 ways to optimize your Time-Based Maintenance (TBM) program

Time-based maintenance (TBM), as the name suggests, is maintenance performed on equipment based on a schedule. TBM maintenance is planned maintenance, as it must be scheduled in advance, which means it can be used with both predictive maintenance and preventive maintenance.

Read MoreWhy ERPs are not Maintenance Management Software

Enterprise Resource Planning (ERP) software is great at what it does. Unfortunately, that does not include being an intuitive data capture and workflow tool for your staff. Some of our customers use SAP, Oracle or Netsuite, to manage their business costs, inventory, purchasing, etc. These ERPs are also supposed to be used for maintenance to…

Read More5 ways to optimize your Preventative Maintenance operations overnight

Better scheduling. Better data. Better insights. Preventive Maintenance programs strive to enhance the OEE and performance of machines. But what do you use to enhance the performance of your PM program? Here are some tips for you to consider that may help you increase the efficiency and productivity of your team. 1. Create an accountable…

Read More5 tips on how to digitize your manufacturing operations

“Digital transformation” continues to be a hot topic in manufacturing and organizations are either jumping on the bandwagon or getting woefully left behind. The main goal of digitization is usually to enhance operational visibility, optimize resource efficiency and productivity and, ultimately, building better products for less money.Current CEB research and Frost & Sullivan’s Global Digital…

Read More