Production Management

How Can Digital Transformation Solutions Revolutionize the Factory Floor for Frontline Workers?

How Can Digital Transformation Solutions Revolutionize the Factory Floor for Frontline Workers? Revolutionize your factory floor with digital transformation solutions like Weever, empowering workers with automation, real-time data, and ease of use. Manufacturing is undergoing a seismic shift, driven by advancements in technology and a growing need for efficiency, adaptability, and communication. At the heart…

Read MoreWhy digitize your paper-based operations?

Weever specializes in digitizing operational workflows. We work with organizations of all shapes and sizes who are frustrated with paper forms and spreadsheets. They want to save money, become more efficient, and spend their time more wisely.

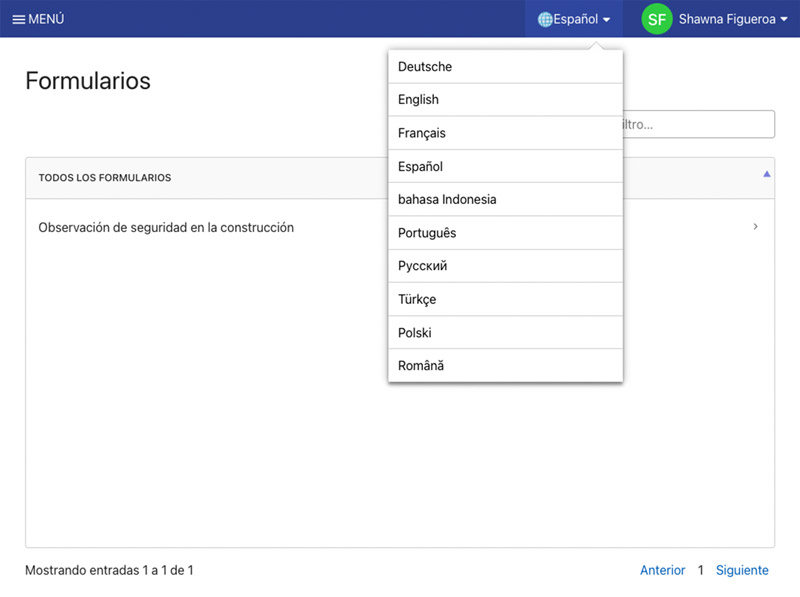

Read MoreWhat is Software Localization?

What is Software Localization? Andy Pritchard | April 6, 2022 | 5 min read What is Software Localization? Localization in software refers to an application changing state based on the language settings selected by the user. Localization considerations can include currency denominations and all “local aspects” of a culture or geographic area that influence…

Read MoreWhat is Root Cause Analysis and how does software help?

What is Root Cause Analysis and how does software help? Andy Pritchard | March 24, 2022 | 5 min read Root Cause Analysis (RCA) is a process that is usually required as part of other larger processes. Whether you are performing a CAPA (Corrective and Preventive Action) for a product defect or an Incident…

Read MoreHow to remove wasted administration time from your audits

How to remove wasted administration time from your auditing process Andy Pritchard | March 23, 2022 | 5 min read Audits are usually required by law, can include layers of complexity and stiff fines if completed incorrectly. Digitization helps to elevate engagement, simplify administration and ensure compliance requirements are met. How do Audits work? Audits…

Read MoreWhat are F-tags and why digitize them?

What are F-tags and why digitize them? Andy Pritchard | March 17, 2022 | 4 min read F-tag is a visual work order system where staff apply paper tags to machines when a process abnormality is observed. “F” stands for Fuguai, which is Japanese word that means “deviation” or “abnormality”. F-tags can be for…

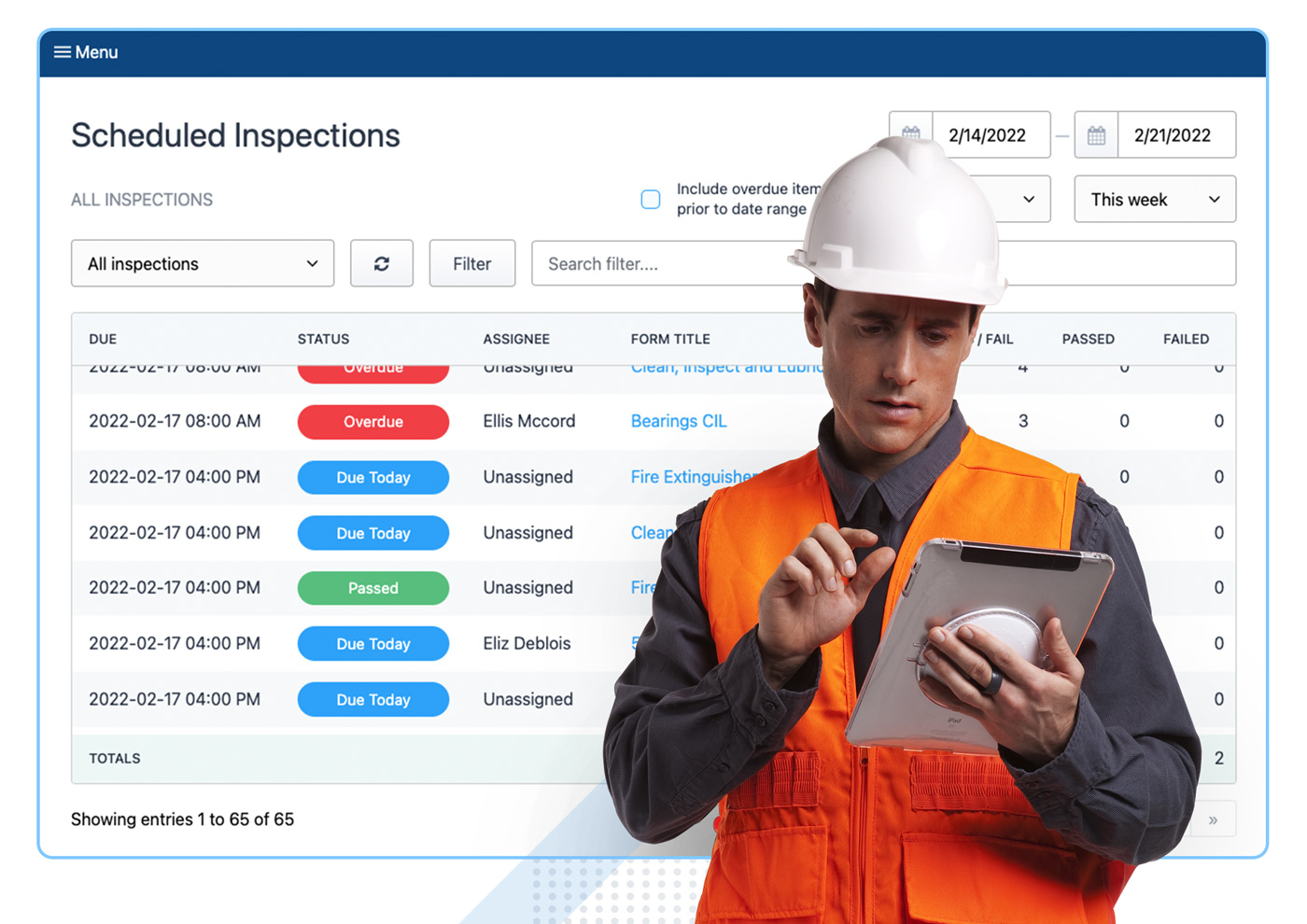

Read MoreWhy are paper forms insufficient for inspection schedules?

Digitizing an inspection schedule takes some effort, so you want to get it right the first time. As you have probably discovered if you’re managing an inspection schedule, paper forms are not ideal for ensuring inspections are completed correctly and on time.

Read More4 ways to reduce waste from your Continuous Improvement process

Kaizen is the process of incrementally improving processes by eliminating “waste”. Small improvements over time can have a huge impact on productivity and the bottom line. Waste can come in many forms, including unnecessary inventory, physical movements and scrap. Kaizen only works if everyone is involved, which includes top management and, more importantly, the workers…

Read More