5 Tips for Remote Factory Management

Andy Pritchard | January 3 2021 | 5 min read

Remote Factory Management

The recent global COVID-19 pandemic has awoken the world to the need for social distancing to combat its spread and “flatten the curve”. Even after the initial lockdown is lifted, how we work could be altered for a long time afterwards as scientists are uncertain how long it will take to create and distribute a vaccine. If the period is 12-18 months as some suggest, we’ll need to find creative solutions to keep operations running while keeping employees safe. We are at the crossroads where Industry 4.0 and modern Environmental Health and Safety are converging.

Most manufacturing in North America is considered essential services. While we are grateful our employment is protected, our challenge is that frontline operators, inspectors, and maintenance staff need to be physically on-site to manage operations.

Reducing employee density on the shop floor and cleaning surfaces that could infect our workforce is now a priority. As part of social distancing efforts, staff that work mostly from an office could theoretically work from home, even if it's just part-time. The caveat of course is they need to have the resources and procedures available to do so. If done correctly it could result in fewer trips to the factory floor.

There are many advantages to digital transformation, and one is being able to manage operations in real-time from anywhere in the world… including your couch!

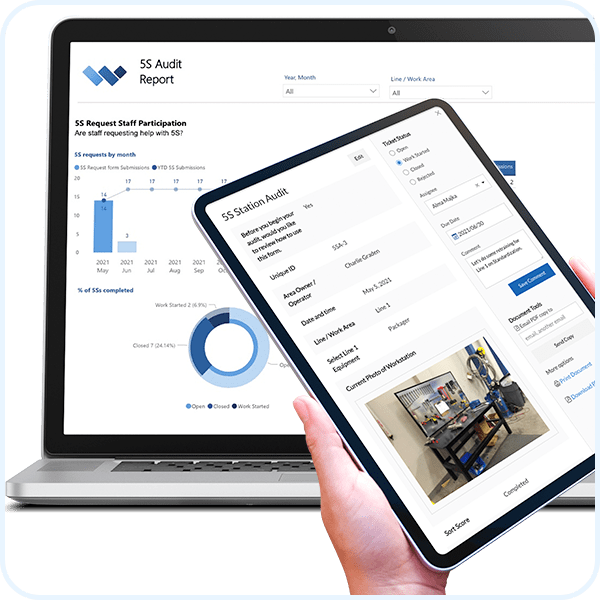

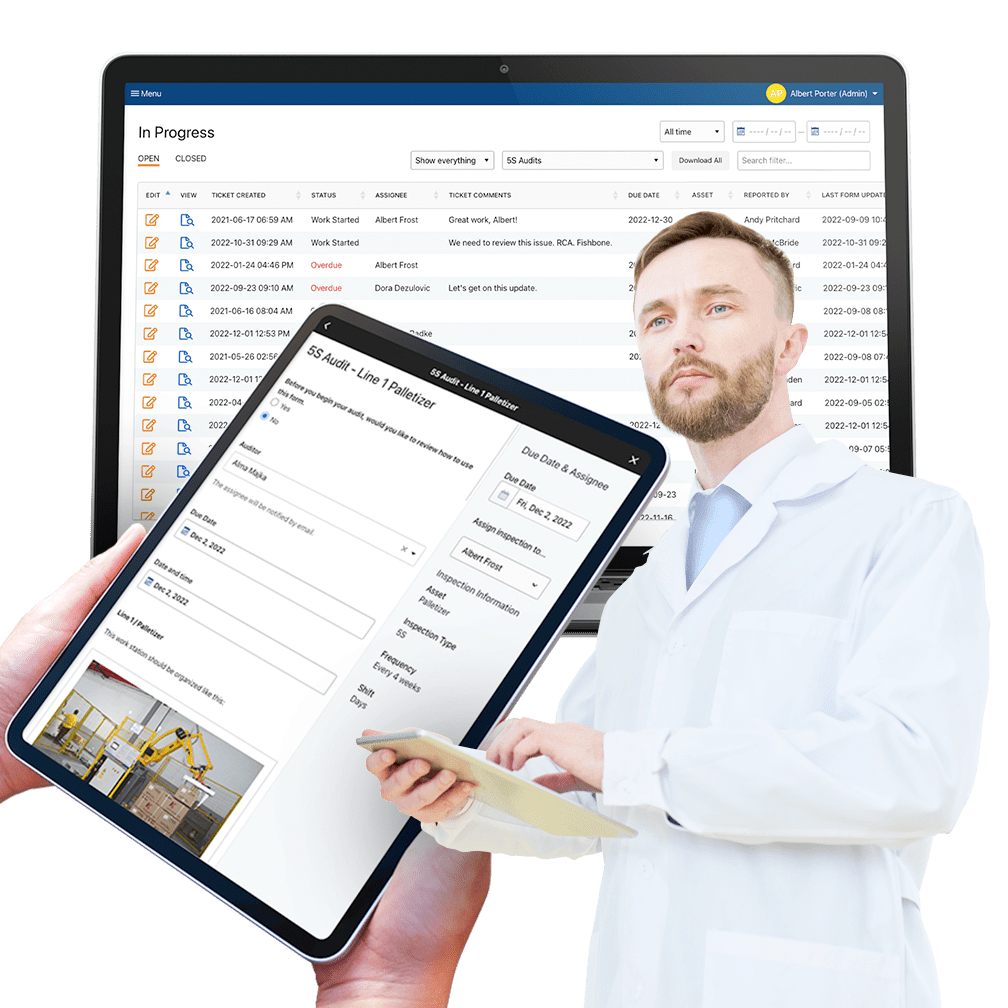

Weever offers cloud-based digitization software specifically designed to accelerate factory operations. Operators collect data from the line that is automatically added to reports and workflows that are managed by supervisors. Assign, schedule, perform follow ups, and do analytics - all automated and accessed via browser from any device, anytime, anywhere.

Here are a few considerations if you are interested in going down this path.

5 Tips for Remote Factory Management

1. Wifi

In order for factory digitization to work the first step is setting up a reliable internet connection. Most of our customers use tablets that are available on each line and connected to the internet via wifi. Our software is “device agnostic”, so you can also use computers that are hardwired to the internet using ethernet cables.

Having wifi available on the factory floor opens up a lot of options for digitization software to accelerate your plant operations.

If you are worried about your staff using the wifi for other distracting means, you can keep the password private and/or restrict the website URLs that can be accessed from the network. This is done by adding an Access Control List (ACL) or “whitelist” to your router. Any IT person can do this easily, or you can watch this quick tutorial and do it yourself Most routers have ACL, including Linksys and TP-Link.

You can run into issues with signal strength if you have machines and breakers that emit a lot of electrostatic discharge. This may require placing routers close to these machines and expecting a shorter signal diameter.

Routers are pretty cheap nowadays. You can get a good one for about $40. Most routers can effectively service a 300 ft diameter. If you take into account extra routers that might be required for electrostatic disturbance, you can roughly estimate your costs for routers by dividing your total area by 300, adding 300 for each area you think the signal might be disturbed and adding some additional costs for ethernet cables to service the wifi routers. You can alway return the additional routers you purchase and do not use.

Before completing the final installation, walk around your facility with a laptop to test the signal strength. You can then use this information to optimize the connection coverage.

2. Disinfected Devices vs Contaminated Paper

Scientists are learning more about how Covid survives on surfaces every day. One advantage of using tablets instead of paper is that devices can be regularly disinfected. Try spraying disinfectant on paper and see what happens! This paper is often then passed back and forth between departments and clerks who do data entry. It’s always been inefficient, but now it could endanger the wellness of your admin staff!

Consider having an alcohol-based disinfectant close to the tablet or computer you are asking your staff to use. Simply request that staff wipe down each device before using. Even if they are using gloves incorporating them into regular EH&S workflows on the line are now essential.

3. Use Digital Dashboards & Group Conferencing

Some of our customers use digital dashboards to review KPIs and Action Items before the shift. You can facilitate the meeting remotely using Zoom Conferencing or a simple conference call.

Some customers show the dashboard on a large TV and go through each KPI and action item before the shift. You can use the time to request information about projects, assign action items, refresh on safety procedures, and ensure everyone is on the same page about the shift plan.

4. Remote SOPs

It is important to standardize how you manage workflows remotely with your frontline staff so that operating procedures are clear. SOPs can be added to any app using the Documents Add-on.

Shift huddles help to engage staff and ensure everyone is on the same page moving forward. In the event of an emergency or high priority event, a call list can be provided at each station or within the app (See “Info Boxes”) to ensure remote workers can be notified and respond quickly.

Alerts can also be added to forms that tell staff what number to call immediately if there is an issue. Supervisors can also be notified immediately based on the type of high priority event (see “Conditional Email”).

Whatever your procedures, it is important to cover them with a Standard Operating Procedure and train your staff appropriately.

5. Device costs vs. BYOD

Most of our customers simply buy iPads for each line. The cost is minimal when compared to the ROI and the risk of theft is low.

We find that higher end tablets, like iPads and Samsung, offer a superior user experience and last longer.

If you are concerned about costs, you can purchase lower cost Android tablets or institute a BYOD (Bring your own device) policy, where workers are asked to use their own device to submit forms. This is not recommended, especially when starting a digital transformation program, as staff can be resistant. But some customers have adopted this strategy successfully.

To calculate your device costs, you can simply take all the areas you want to add a tablet to and multiply it by around $500, which could get an iPad Air 32GB (or equivalent) and a stand. Financing options are also available from BestBuy. Ruggedized tablets and laptops are a great option if your facility is dirty and precipitous by nature or design.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo