Digitization Mavericks

The 3 EEEs of Sustainable Frontline Employee Engagement

Are you part of the 71% of executives that say Employee Engagement is critical to the company’s success?

In order to foster a culture of excellence you need to increase engagement of your employees by ensuring they are Empowered, Energized and Enabled.

Why Frontline Employee Engagement is the most important success factor for Operational Excellence.

We all know we need to continuously improve and innovate in order to remain competitive. We must find efficiencies, increase quality, enhance productivity and keep people safe. The question is not “why” but “how”? How do we create and foster a culture of operational excellence. Operational Excellence (OpEx) is defined as a management framework that…

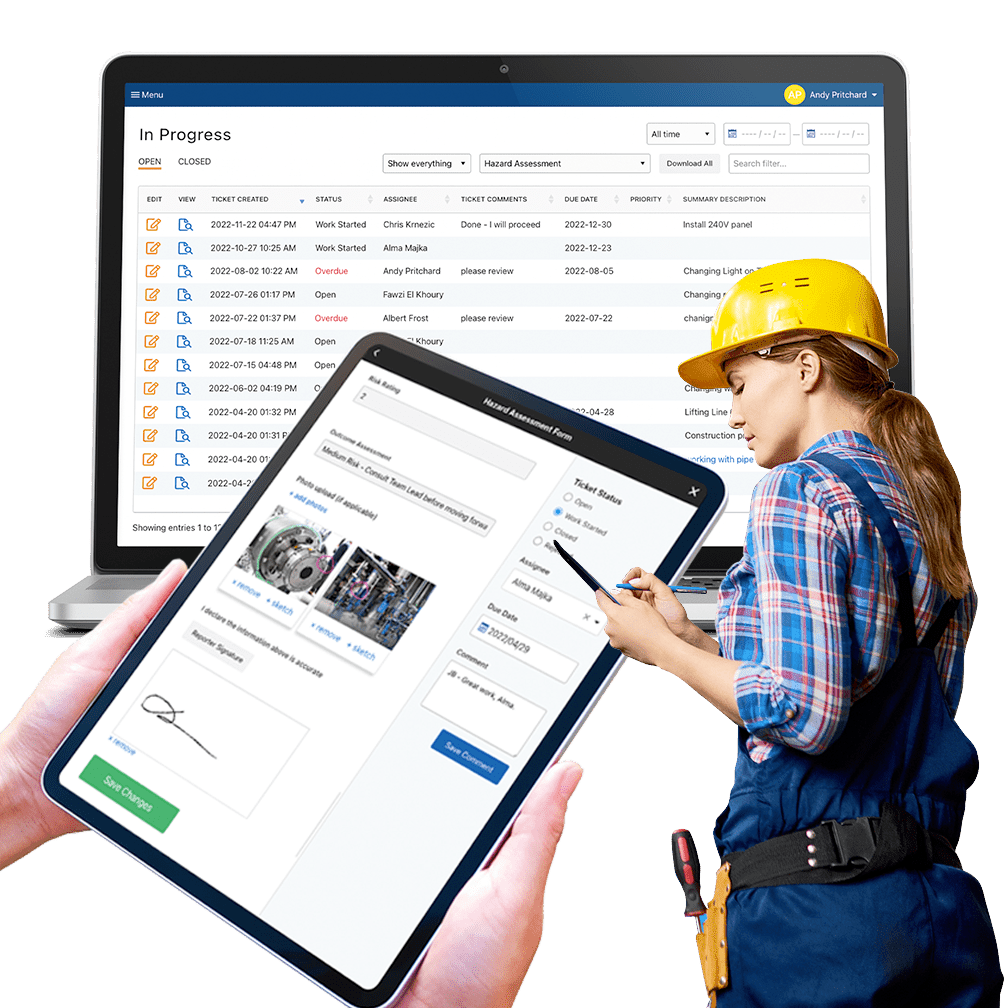

Read MoreWeever Boosts Productivity, Reduces Safety and Quality incidents

Within one year, the factory increased incident reports and other forms of staff participation by over 300% and reduced the average time to close by over 400%. Best of all, they increased their Factory Efficiency (OEE) by 11%!

Read MoreContinuous Improvement Survey Results

Continuous Improvement (CI) is not a core function of manufacturing in that manufacturers can produce their products without engaging in continuous improvement practices. As a result, if not consistently reinforced and supported, CI programs can lose momentum and fail. If CI is a car, then staff engagement is the fuel that propels it forward. CI…

Read MoreHow to protect essential workers in the factory.

Over 20 tips on how to keep factory workers safe and productive during a global pandemic. Weever is a continuous improvement software company. We work primarily with manufacturers in the food/beverage and consumer packaged goods (CPG) space. Our customers are the brands that fill your pantries and bathrooms. As you can imagine almost everything changed…

Read MoreHow to stimulate positive change in your manufacturing facility during a pandemic.

3 tips for enhancing continuous improvement during COVID-19 and beyond. COVID-19 is a global pandemic and there are signs that this virus may change the way we live and work into the future. Many of our customers are food manufacturers who are mandated to continue production. They are taking precautions to keep their staff as…

Read MoreSocial Distancing within the Factory

Most manufacturing is an essential service and must continue during the outbreak of COVID-19. However, that does not necessarily mean that staff cannot socially distance within the factory walls. Manufacturing requires staff to coordinate operations within a defined space. There are many ways that staff interact with each other including: Data Collection: Most factories still…

Read MoreFactory Wi-Fi Setup

REMOTE FACTORY MANAGEMENT The recent global Covid-19 pandemic has awoken the world to the need for social distancing to combat its spread and “flatten the curve”. Manufacturing is an essential service and must continue during the outbreak of COVID-19. However, that does not necessarily mean that staff cannot socially distance within the factory walls. In…

Read More5 Tips for Remote Factory Management

Reducing employee density on the shop floor and cleaning surfaces that could infect our workforce is now a priority. As part of social distancing efforts, staff that work mostly from an office could theoretically work from home, even if it’s just part-time.

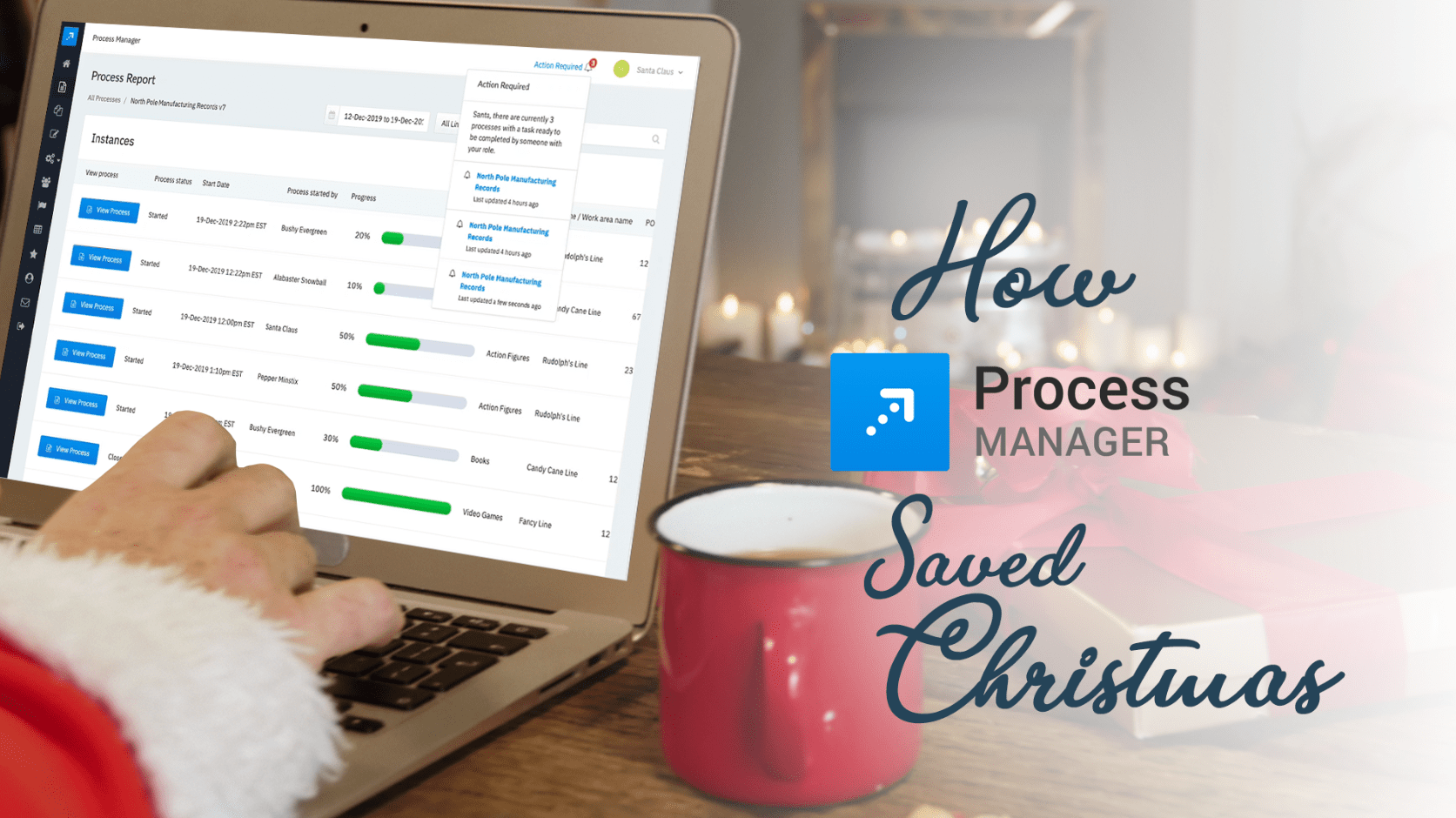

Read MoreHow Process Manager Saved Christmas

‘Twas the night before Christmas, and everything in Santa’s workshop was a mess. Learn how Santa cleaned up operations just in time to save Christmas!!! Download the Product Brochure Learn more about how Process Manager works and the effects it will have on your business. Let’s get started. Free Trial Preview modal- Let’s get your…

Read More