Why Frontline Employee Engagement is the most important success factor for Operational Excellence.

We all know we need to continuously improve and innovate in order to remain competitive. We must find efficiencies, increase quality, enhance productivity and keep people safe. The question is not “why” but “how”? How do we create and foster a culture of operational excellence.

Operational Excellence (OpEx) is defined as a management framework that is achieved when each and every employee can see the flow of value to the customer, and has the ability/motivation to fix that flow before it breaks down. The 3 major components of Operational Excellence are:

- All employees share an intimate and ever evolving understanding of the customer value the organization is delivering.

- Employees understand the processes within the organization that are engaged to deliver that value and can recognize/fix deviations before they reach the customer.

- Employees are relentlessly pursuing perfection through continuous improvement.

According to McKinsey & Company as well as numerous other studies, the large majority (over 75%) of OpEx initiatives fail to achieve ROI.

The reason: Operational Excellence requires extra work.

Manufacturers can simply manufacture their products. Employees can simply resign themselves to the specific role for which they were hired - i.e. watch the line for defects, ensure centerlines are kept, document abnormalities. And that’s it.

Operational Excellence doesn’t just happen because you want it to. In order for Operational Excellence to be successful and attain a positive ROI, organizations must nail 3 interrelated requirements.

- Corporate Alignment - It is a top priority of leadership and continuously reinforced in communications to staff.

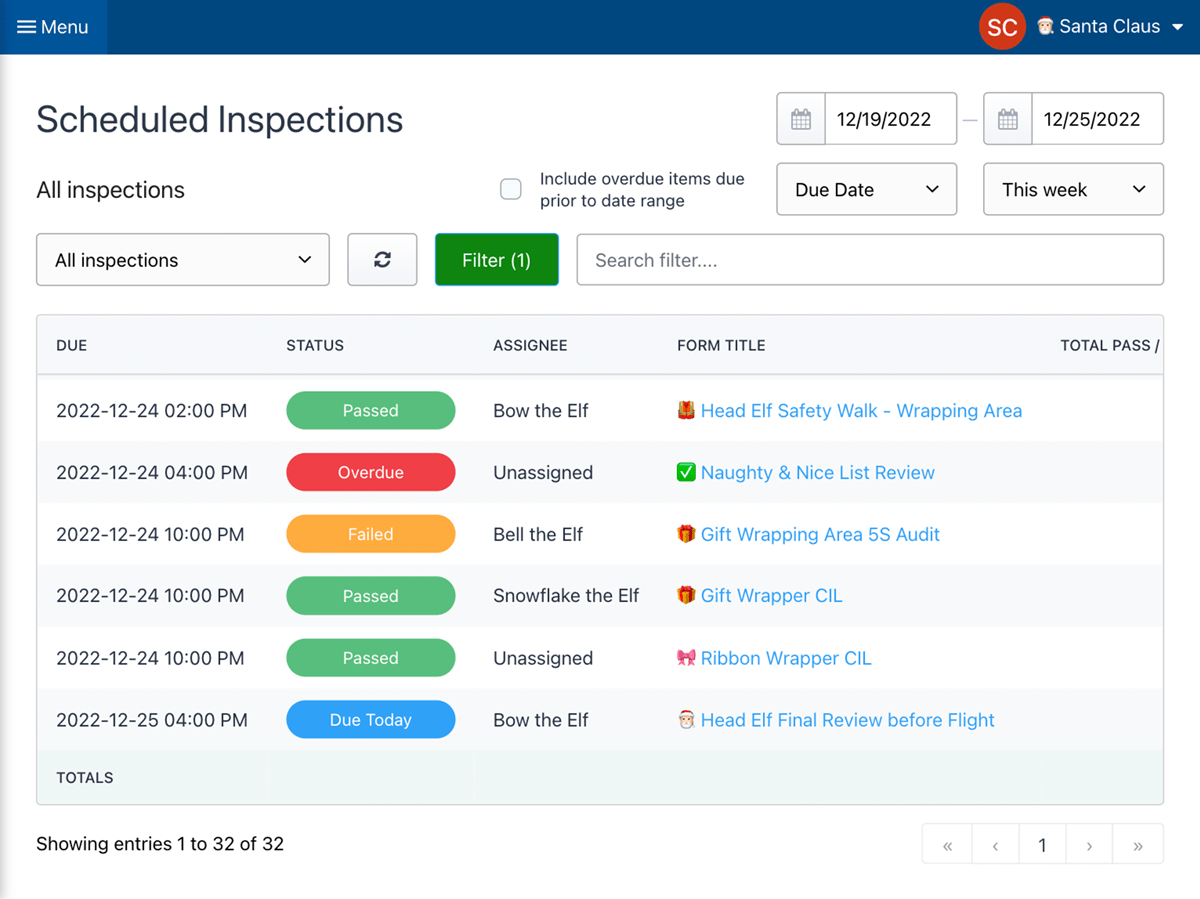

- Tools and Resources - Staff have access to tools, systems, resources and training that allow them to be successful and participate.

- Employee Engagement - Staff are empowered, excited and enabled to do the extra work required to move projects forward, uncover insights and improvement opportunities, etc.

It’s no secret that employee engagement boosts individual, team and overall operational performance. According to Food Engineering Mag, a culture of employee engagement translates to positive outcomes for overall production and operational efficiency.

The “2012 State of the American Worker” report from Gallup made clear the impacts of improved engagement on key performance indicators. According to the survey, increased employee engagement results in:

- 40% reduction in safety-related incidents

- 40% reduction is quality defects

- 37% reduction in absenteeism

- 20% increase in productivity

- Over 20% increase in profitability

To use a simple analogy, if your OpEx program is an automobile, Corporate Alignment is the steering wheel, Tools and Resources is the engine and Employee Engagement is the fuel upon which it runs.

- The car can move forward without a steering wheel but no one knows where we are heading and it is probably better to slam on the brakes before you run into a tree.

- The car can theoretically move forward without an engine, as many of us have experienced when we run out of fuel. It requires a lot more effort to get the car from A to B, however.

- The car is entirely worthless, however, without fuel to run it. The steering wheel is meaningless and the motor is just a weight that makes it harder to move.

What this analogy is trying to illustrate is that all 3 factors are hugely important, but the most important is Employee Engagement.

Most of our customers have found us because they are seeing an ROI in Operational Excellence but they are lacking the tools and resources to get to the next level. They are using paper forms and spreadsheets to move projects forward. This illustrates that a high degree of Employee Engagement can overcome inefficient systems.

We have also worked with organizations that have not fully bought into OpEx principles. Generally, a manager has been trying “some new things out” with a highly engaged team and is looking for a low-cost way to scale the processes and sell the approach to the rest of the organization. This illustrates that highly engaged employees are not just the fuel but the “spark” that ignites the movement.

Ultimately, you can have the best corporate intentions and deploy the most convenient systems. But if your staff is not engaged, the program will fail. As the old saying goes, “Where there is a will, there’s a way.” Employee Engagement is the “will” and Operational Excellence is the “way”.

Weever has been on the forefront of helping global F&B and CPG manufacturers realign their employee engagement using our innovative suite of products.

We help drive the desired behaviours by incentivizing your staff, rewarding them when they go above and beyond to participate in your CI or lean culture initiatives.