Weever Boosts Productivity, Reduces Safety and Quality incidents

Andy Pritchard | June 21, 2020 | 5 min read

Background

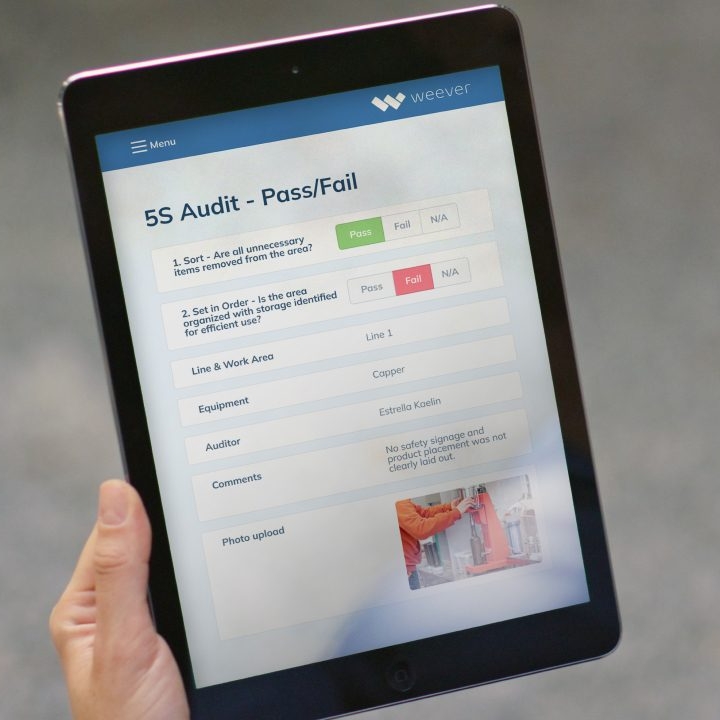

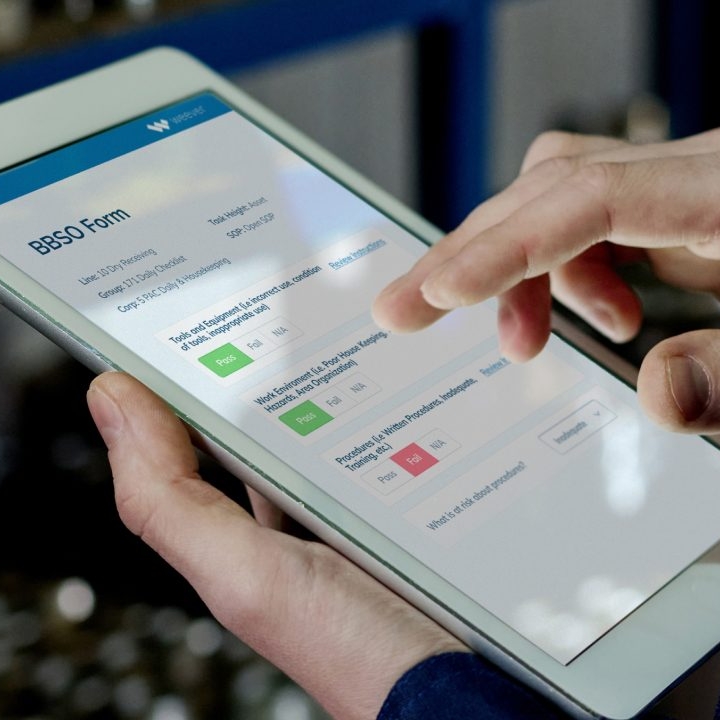

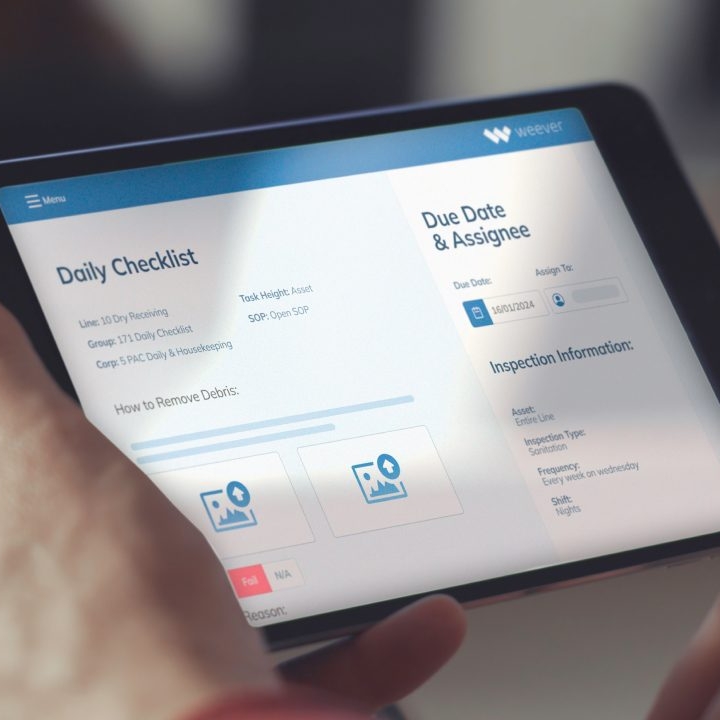

Global CPG manufacturer wanted to digitize Operational Excellence and Continuous Improvement (CI) workflows.

Challenge

- Each department was having issues with:

- collecting data efficiently from staff

- managing workflows and operational visibility

- Sharing data and generating reports to inform improvement cycle processes.

- Their current paper form and spreadsheet system required a lot of time to administer and not delivering expected results.

- Paper form data capture was inefficient and prone to errors and staff spent days rekeying non-digital data into spreadsheets.

Solution

- The factory chose Weever primarily because it offered the flexibility they required to adapt to their unique requirements.

- Instead of a lengthy implementation, Weever's cloud-based software was up-and-running in 2 weeks.

- Weever customer success staff worked with the factory’s app administrators to build forms and train staff.

Results

Within one year, the factory increased incident reports and other forms of staff participation by over 300% and reduced the average time to close by over 400%. Best of all, they increased their Factory Efficiency (OEE) by 11%!

- Increased Factory OEE by 11%

- Reduced average time to close for reported incidents by over 400%

- Increased incident reports and staff participation by over 300%

“Weever has changed how I run our business.”

Ingrid K., Plant Director

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo