Digitization Mavericks

Transforming Safety Reporting with Weever’s Digital Solution

Discover why Kody has found Weever, an innovative operations management software platform specializing in Food and CPG manufacturing, to be an indispensable tool for managing Walmart’s BBSO program.

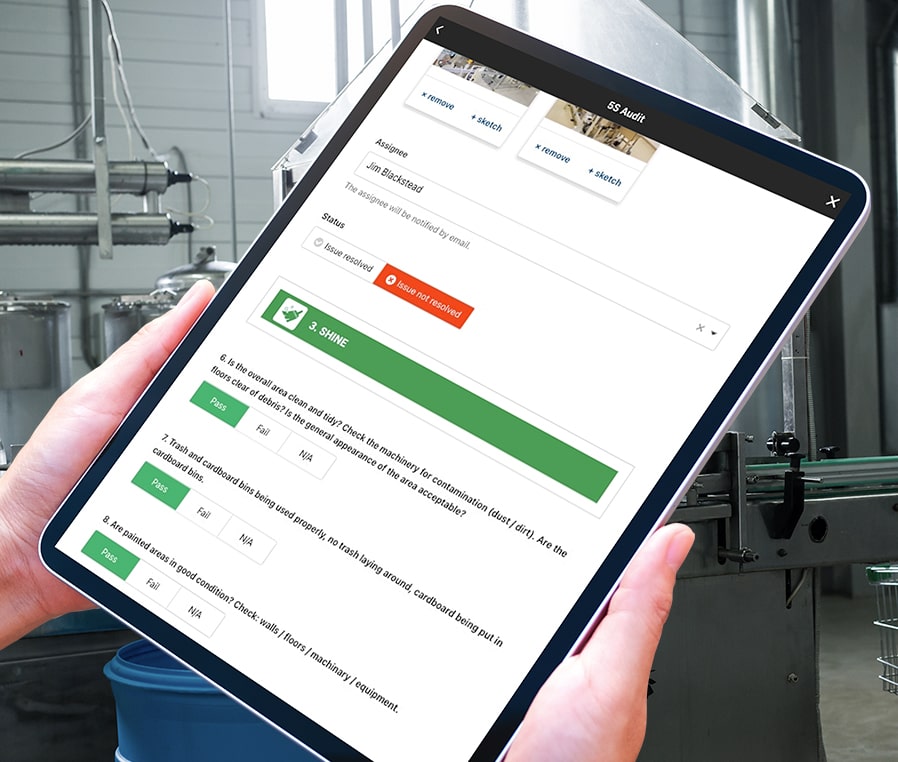

Read MoreWhat can software do to enable 5S Auditing

The traditional approach to 5S audits, reliant on manual tracking, can be time-consuming and prone to errors. Software play a pivotal role in enhancing the efficiency of sustaining 5S gains.

Read MoreHow to Build a 5S Implementation Roadmap

Crafting an implementation plan or roadmap is pivotal to ensure a smooth transition and successful adoption of 5S principles.

Read MoreHow to gather data to support your 5S business case

To substantiate the case for 5S adoption, gathering benchmark data and evidence-backed KPIs becomes crucial. The right KPIs not only provide quantifiable data but also serve as compelling evidence to support the business case for 5S implementation.

Read MorePain Points Solved with 5S

When planning your 5S implementation, it is important to align the program’s objectives and benefits with the strategic priorities of your organization.

Read MoreHow to Build a Business Case for 5S Implementation

Building a compelling business case for implementing a 5S program is critical in garnering support, securing resources, and laying the foundation for a successful initiative.

Read More5S Recognition: Celebrating Achievements

Celebrating success and recognition are integral to this process, serving as catalysts for motivation, fostering a culture of excellence, and reinforcing positive behaviors.

Read More5S Audit Reporting: Comprehensive Guide

5S Audit Reporting entails the compilation and analysis of audit findings to provide actionable insights and drive continuous improvement efforts.

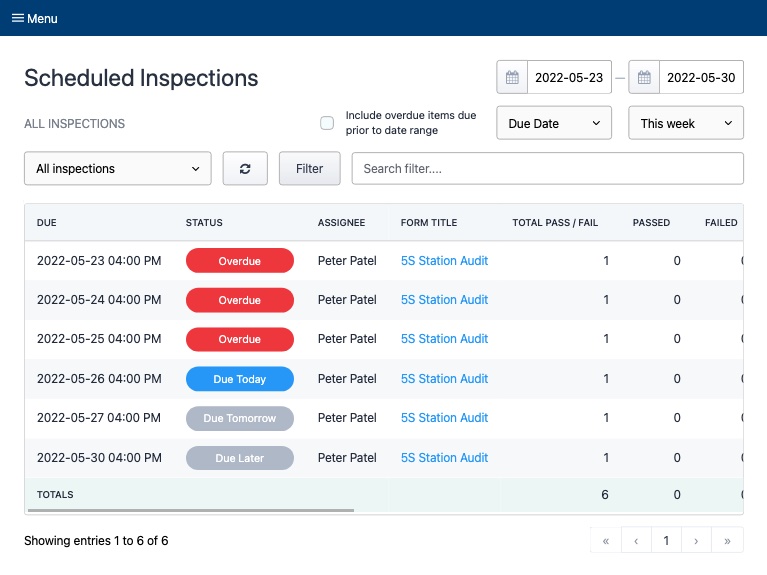

Read MoreScheduling 5S Audits: Implementation Guide

The scheduling of 5S audits is instrumental in fostering a culture of continuous improvement, as it ensures regular and systematic evaluations of workstations.

Read MoreHow to Conduct Successful 5S Audits

5S auditing is a critical tool to evaluate the effectiveness of 5S implementation, identify areas for improvement, and reinforce a culture of cleanliness, organization, and efficiency within workplaces.

Read More