Search Results: 7 tips to ensure successful 5s audits/paged 7/6/

7 Tips to ensure successful 5S Audits

The steps involve the worker going through everything in a space, deciding what’s necessary and what isn’t, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

Learn more ...5S Auditing Best Practices

A crucial part of Sustain is completing regular 5S Audits, which help maintain gains from your 5S Action Plan and also find new ways to make your workstations more efficient, safe, and productive over time.

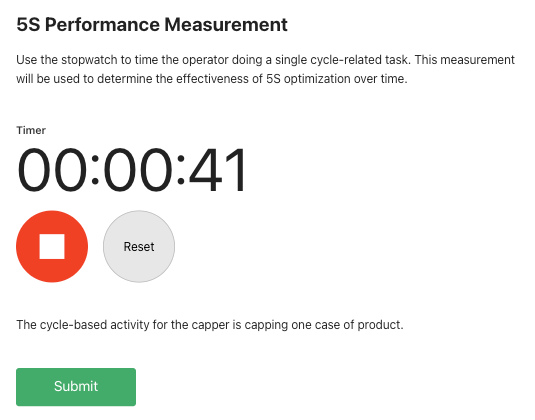

Learn more ...Measure the Real Impact of your 5S Audits with Cycle-based Activity Timing

Cycle time is the duration of one production cycle, and it can be used as a metric to identify improvement opportunities in a manufacturing process. By measuring cycle time, managers can identify bottlenecks, waste, and inefficiencies, and develop strategies to improve the process.

Learn more ...Boosting Safety and Efficiency: The Top 5 Benefits of a Behavior Observation Safety System in Manufacturing

The practice of Behavior-Based Safety can have a massive positive impact on the health and safety of your site. The methodology is relatively simple to implement, make safety more “top-of-mind” to staff and, ultimately, reduce incidents. Here are the Top 5 Benefits for implementing a Behavior Observation Safety System that we have witnessed with our customers:

Learn more ...5S Overview – What is it?

In order to be profitable and compete in a global market every company has to effectively steward its resources. It’s been said that waste is a thief. In manufacturing, where waste can take several different forms including wasted time, energy, movement, or materials, this is especially true.

Learn more ...