Maintenance Programs

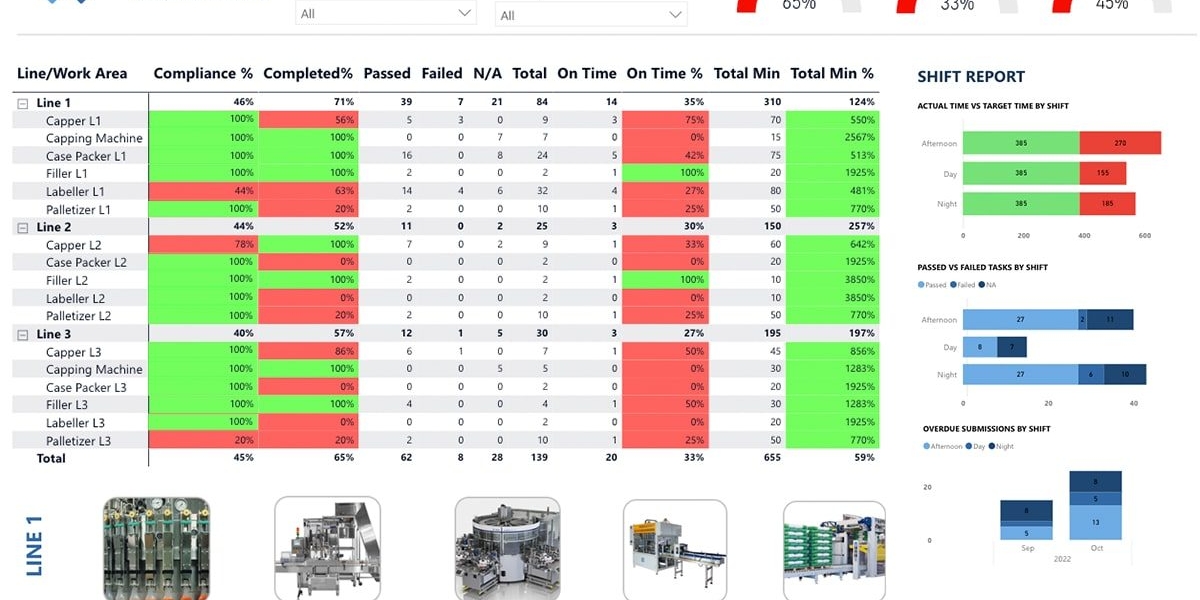

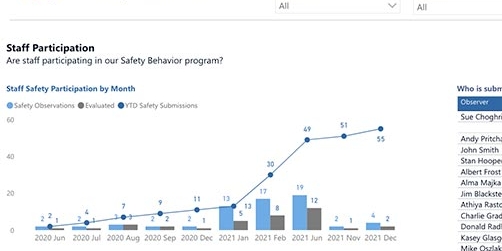

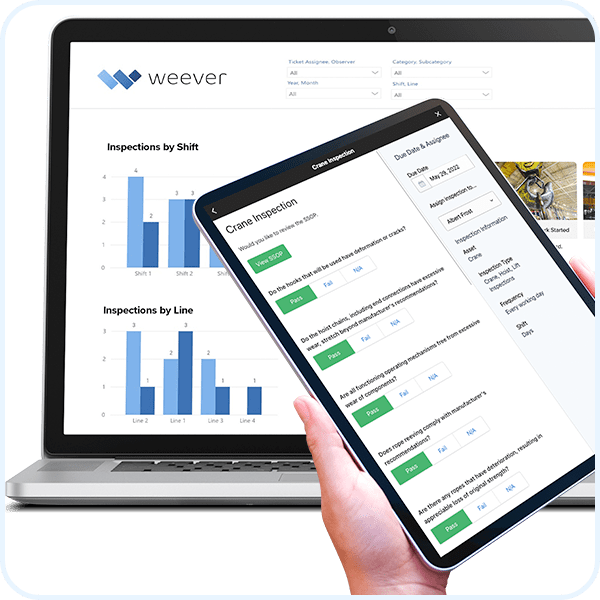

Safety Audits & Inspections

Ensure efficient and compliant completion of safety audit and inspection requirements.

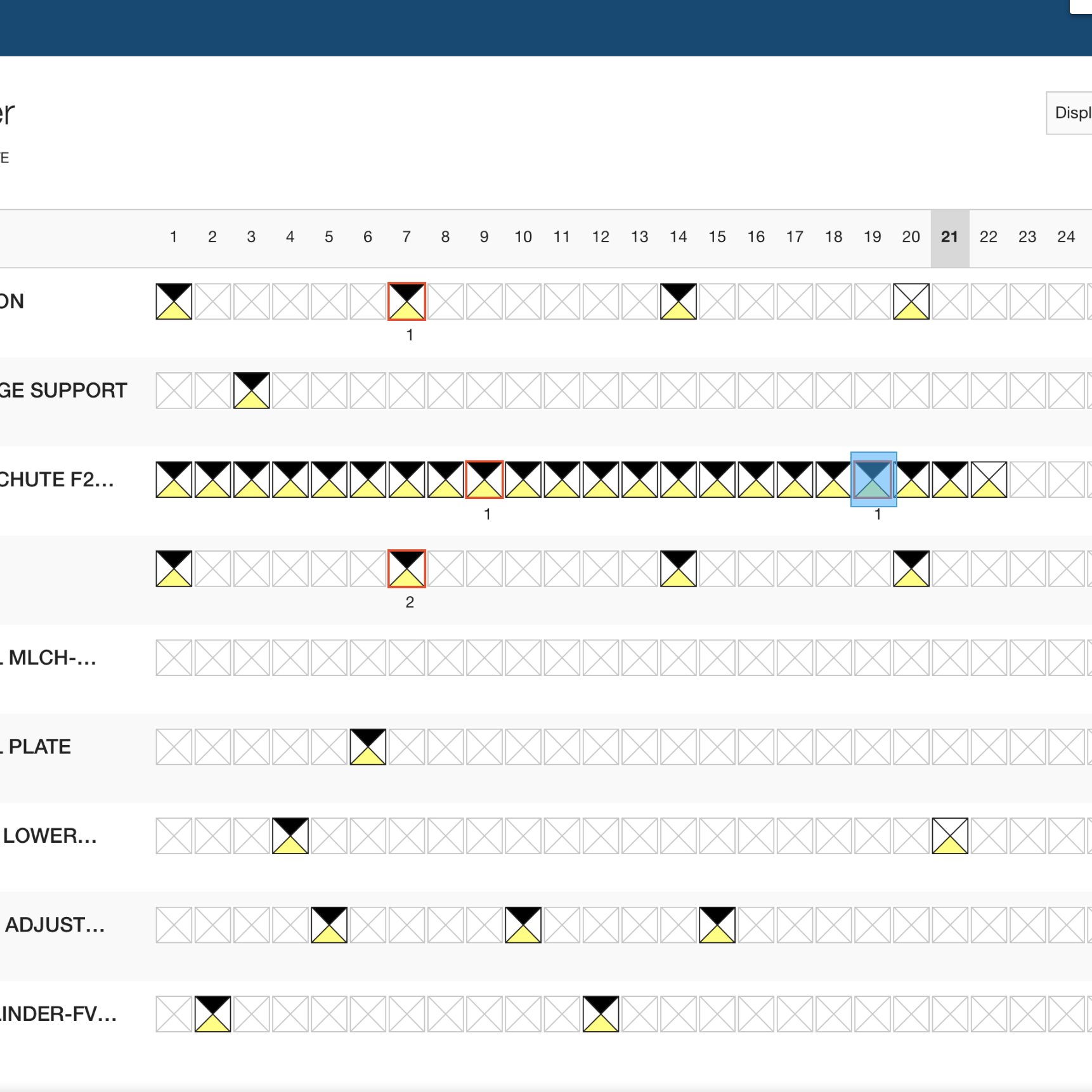

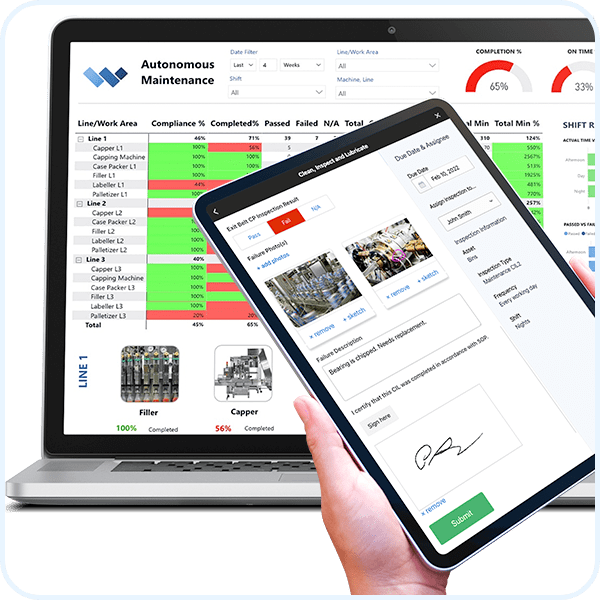

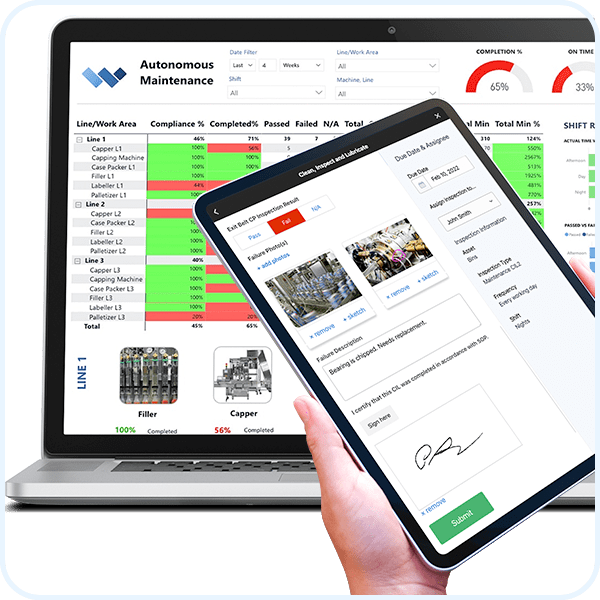

Autonomous Maintenance

Provide cleaning, inspection and lubrication (CIL) instructions and manage schedules. Automatically escalate failed inspections.

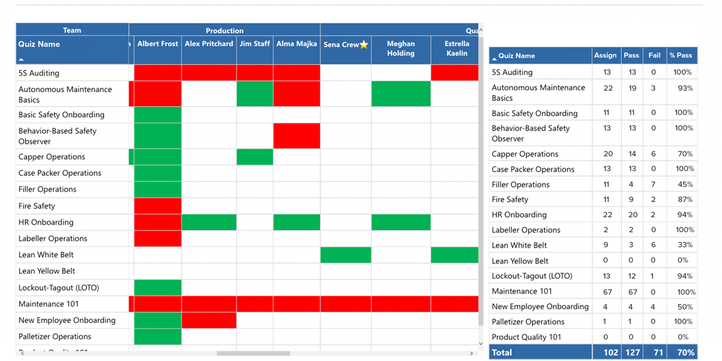

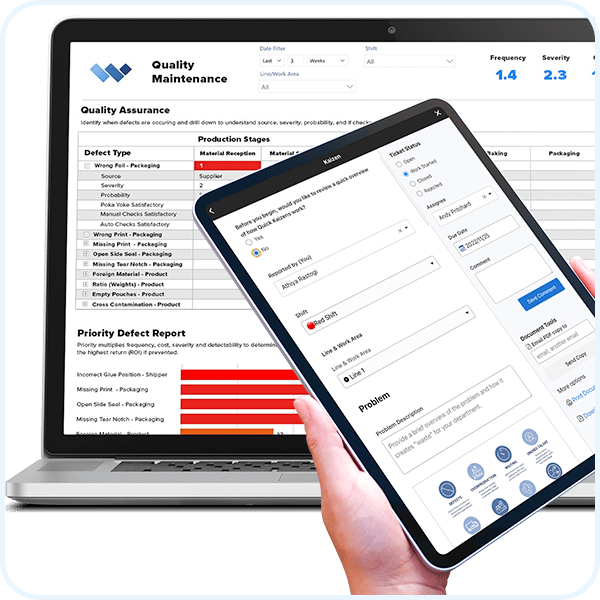

Quality Assurance Matrix

Understand and prevent quality defects within the context of Total Productive Maintenance (TPM).

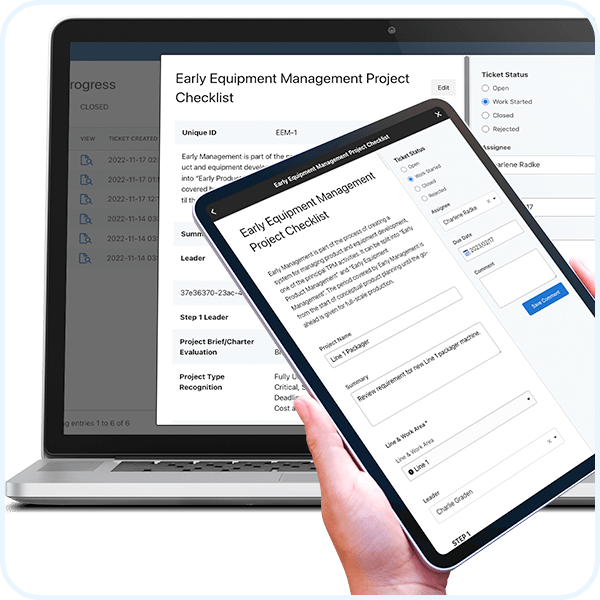

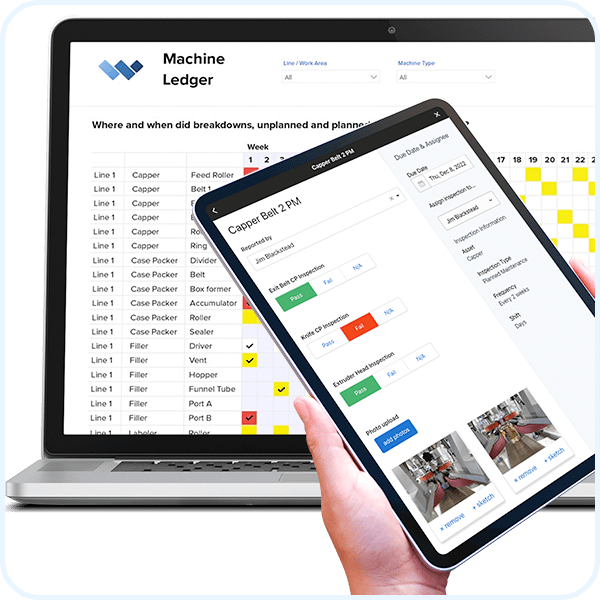

Planned Maintenance Schedules

Create and manage planned maintenance schedules for machines and equipment.

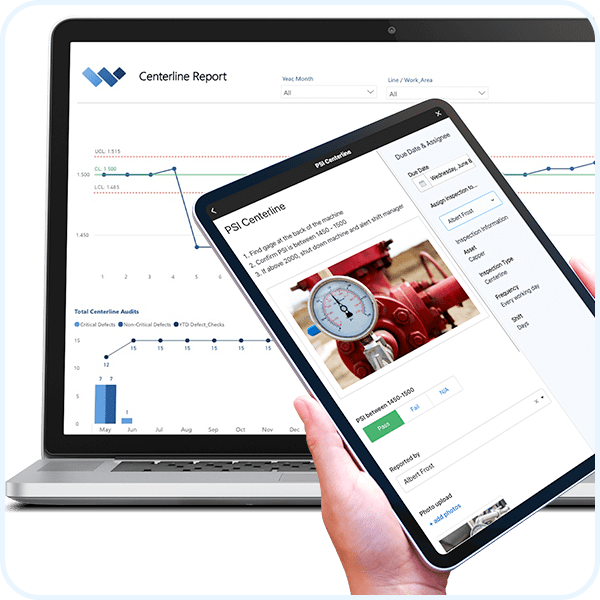

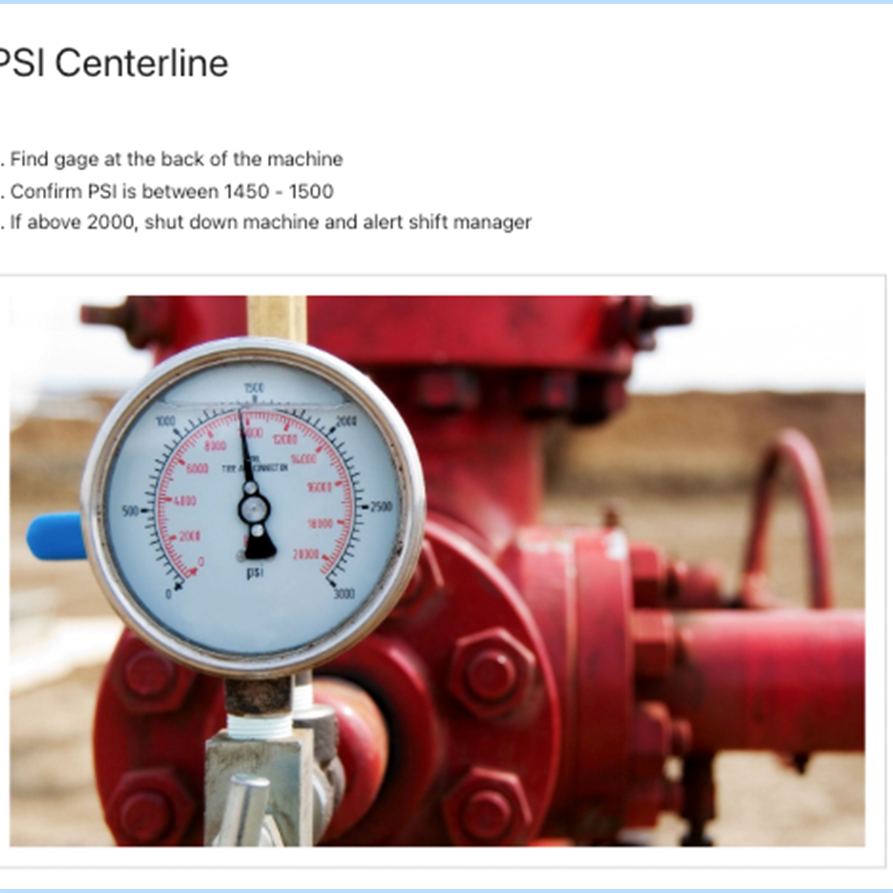

Clean, Inspect, Lubricate (CIL)

Provide instructions and capture valuable data in real-time. Make it easy and ensure compliance.

Machine Pre-Start Inspections & Safety Checks

Create and manage schedules. Provide real-time, on-demand instructions to ensure compliance.

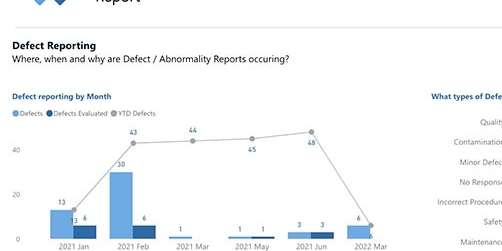

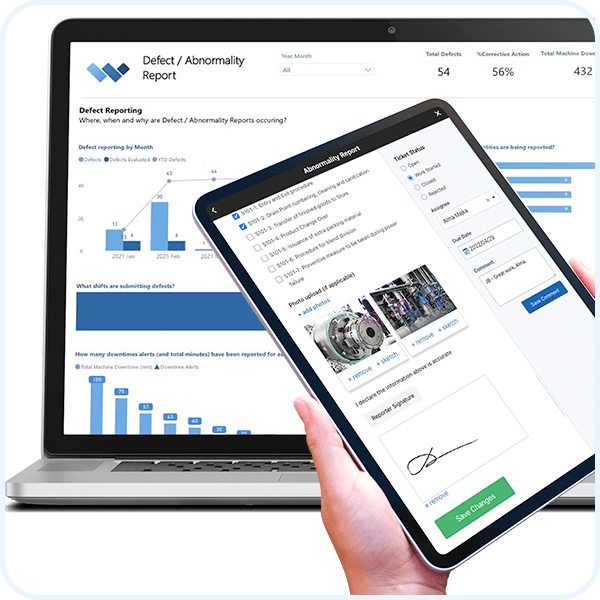

Abnormality Reporting

Make it easy for staff to report Process Abnormalities and for managers to initiate PDCA projects.

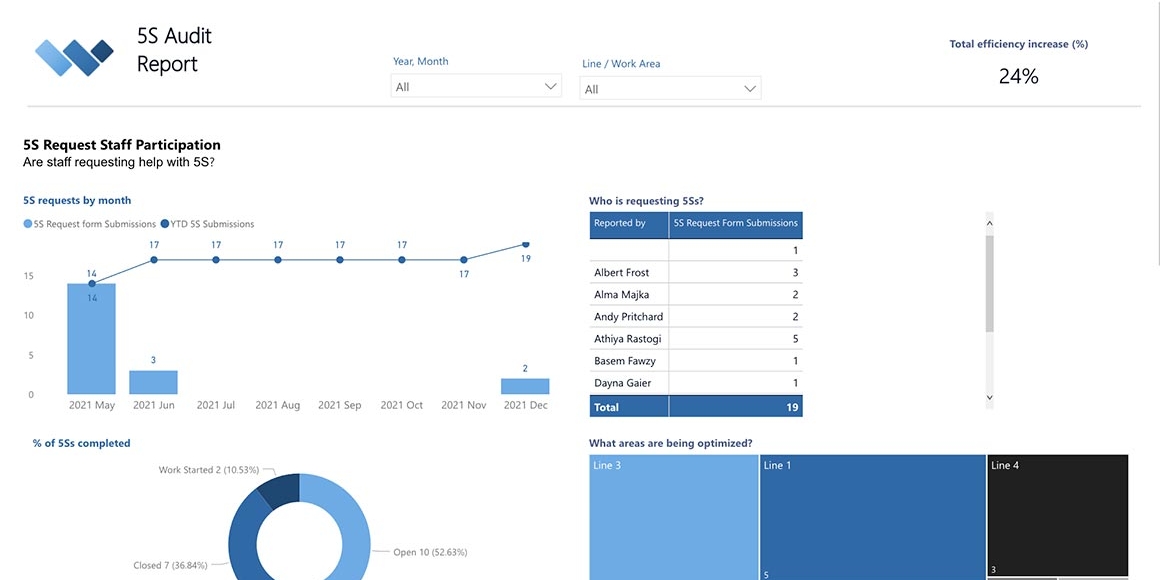

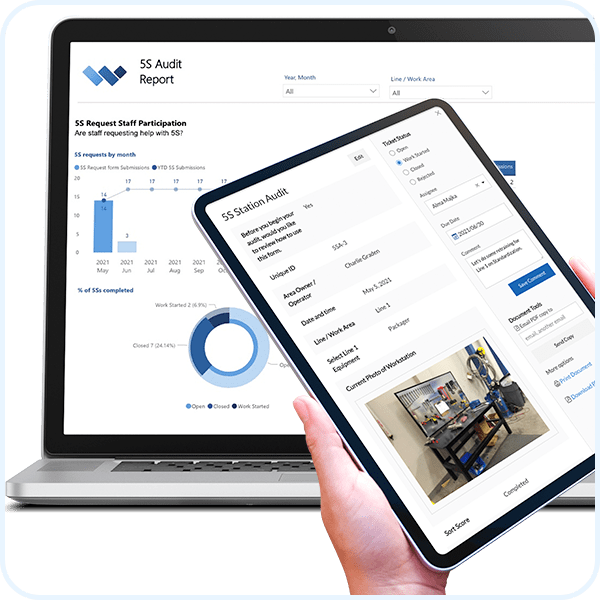

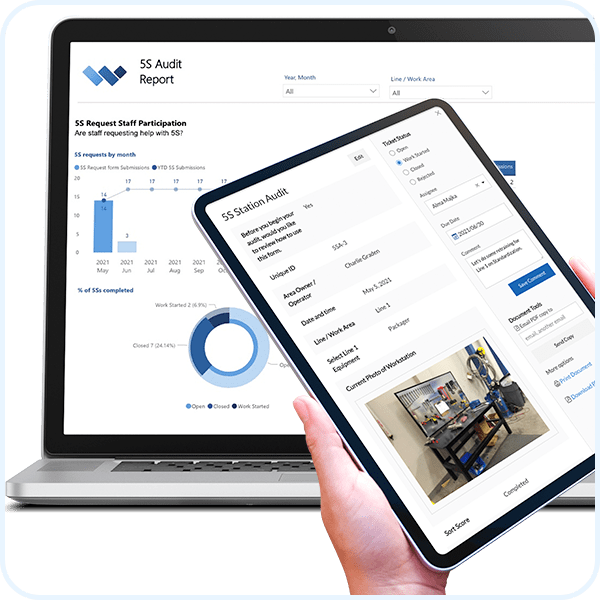

5S Workstation Optimization

Ensure workstations are optimized correctly and improvements are sustained by documenting Sort, Set in Order and Shine steps including photos and videos.

6S Lean: 5S + Safety

Ensure 6S Lean (5S + Safety) audits are completed correctly including photos or video capture.

Maintenance

We work with organizations of all shapes and sizes who are frustrated with paper forms and spreadsheets and want to get more out of their CMMS. They want to save money, become more efficient, and spend their time more wisely.

Ultimate Guide to Success with Autonomous Maintenance

Everything you need to know about how Autonomous Maintenance works and the best practices gleaned from our 10+ years of experience helping organizations achieve success.

Everything you need to know about how Autonomous Maintenance works and the best practices gleaned from our 10+ years of experience helping organizations achieve success.