Quality Programs

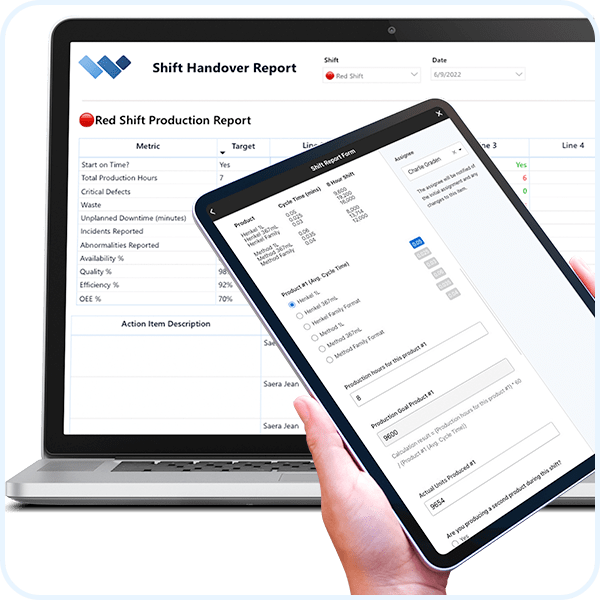

Master Batch Records

Ensure compliance and enhance efficiency. Guide staff through the process to ensure compliance.

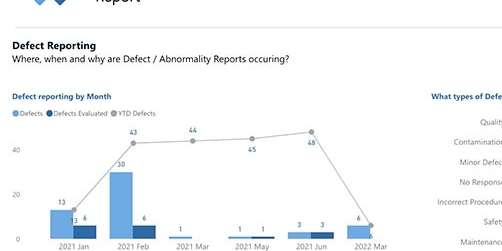

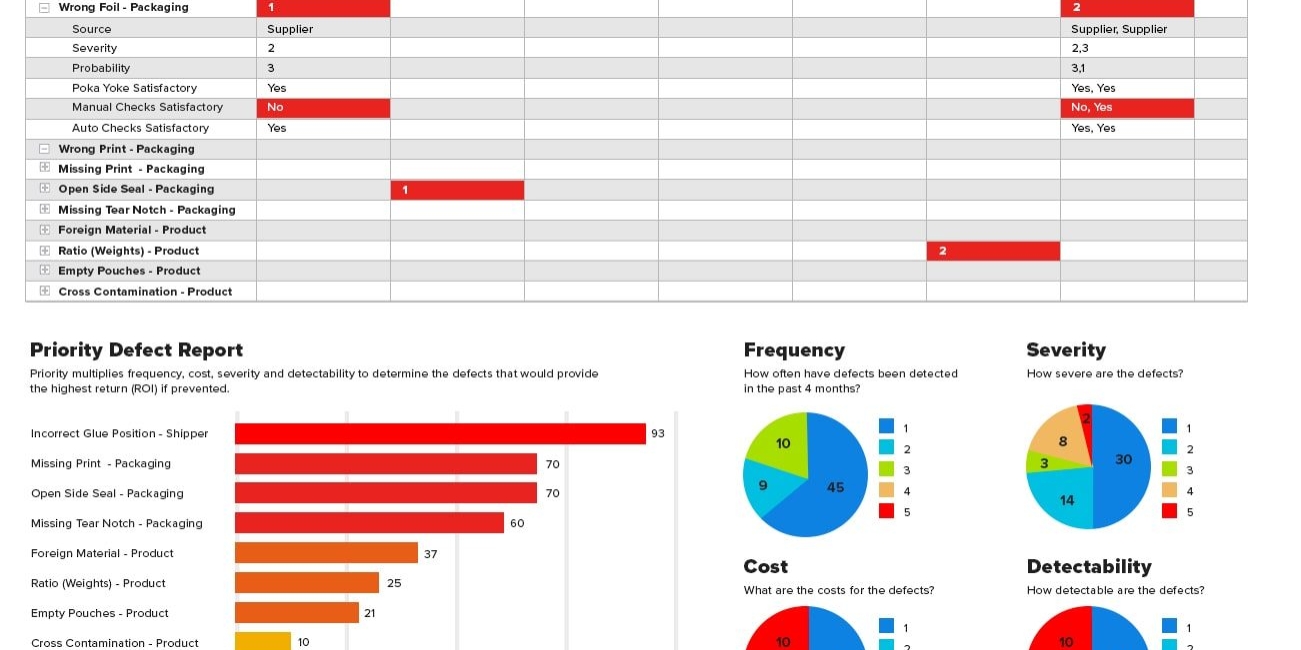

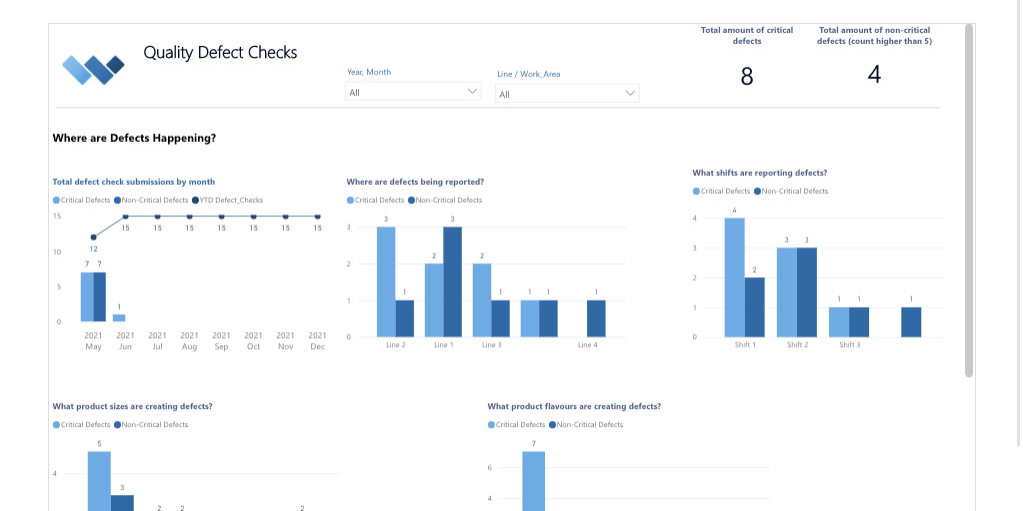

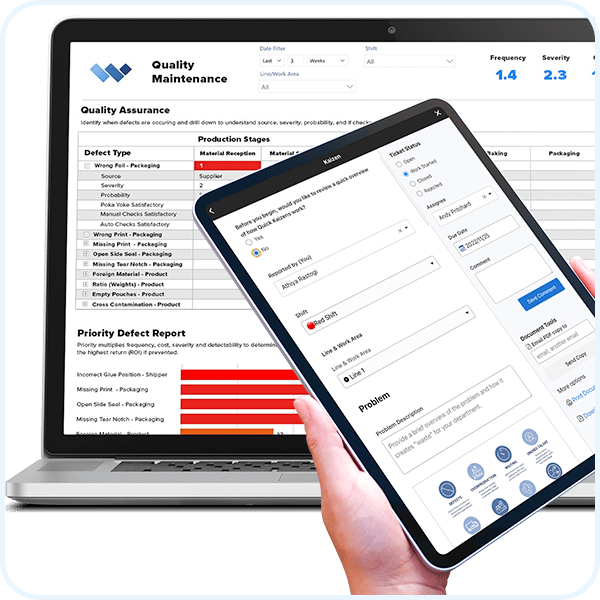

Quality Assurance Matrix

Understand and prevent quality defects within the context of Total Productive Maintenance (TPM).

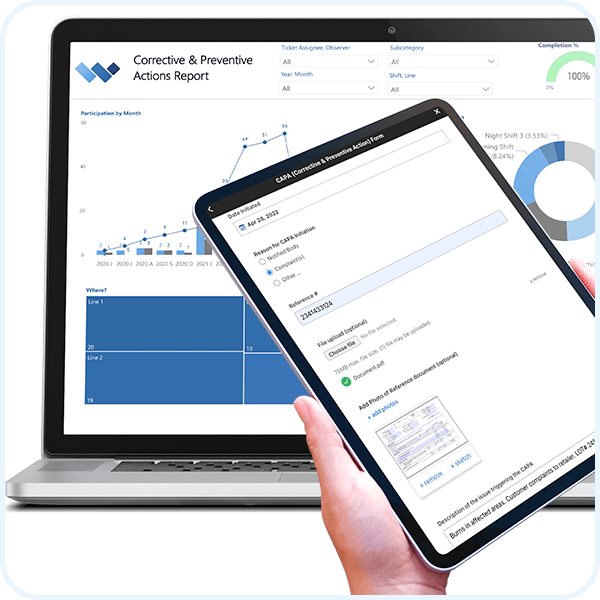

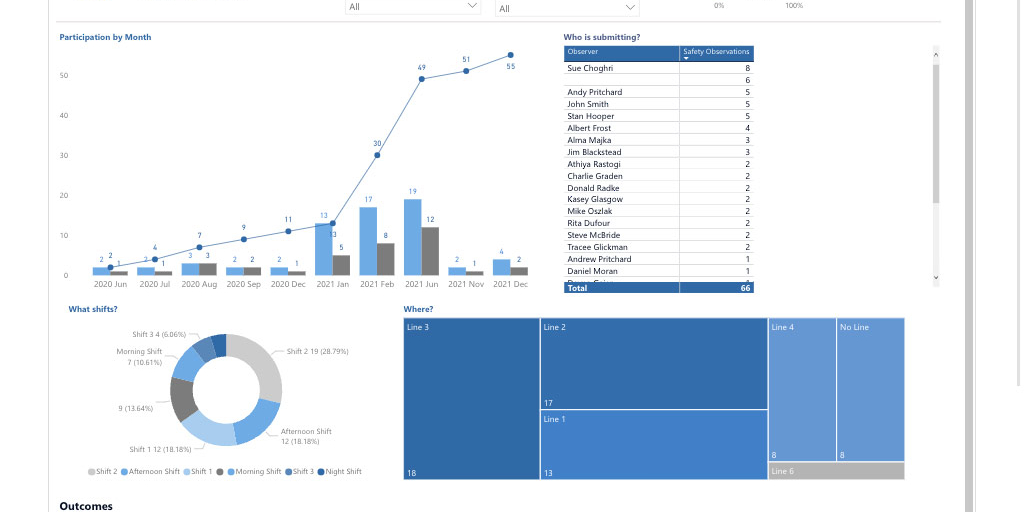

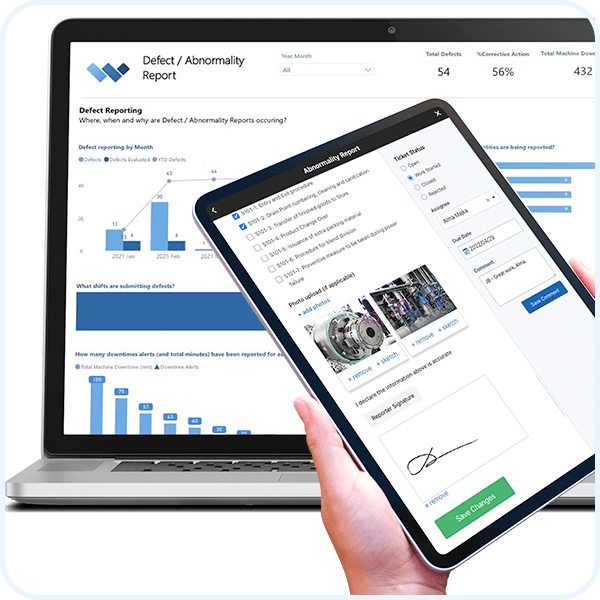

Abnormality Reporting

Make it easy for staff to report Process Abnormalities and for managers to initiate PDCA projects.

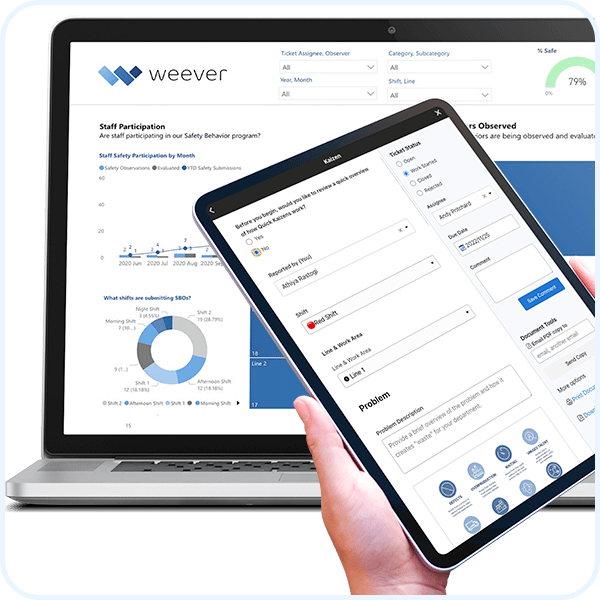

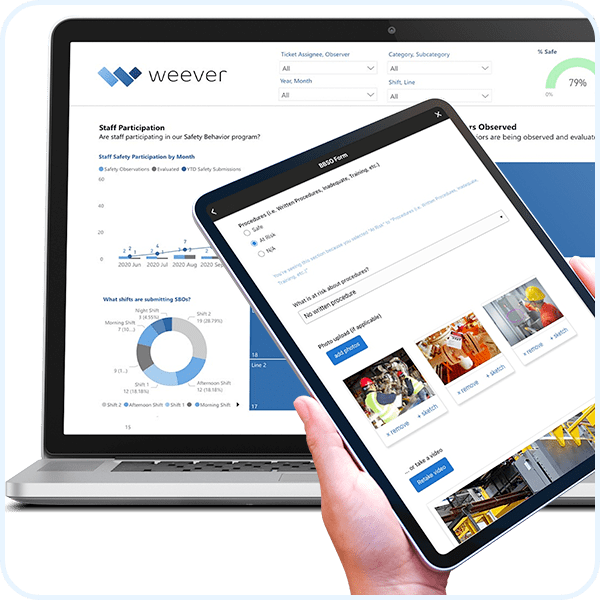

Quality

We work with organizations of all shapes and sizes who are frustrated with paper forms and spreadsheets and want to get more out of their Quality Management System. They want to save money, become more efficient, and spend their time more wisely.

100K+

Global Users

MILLIONS

of jobs completed

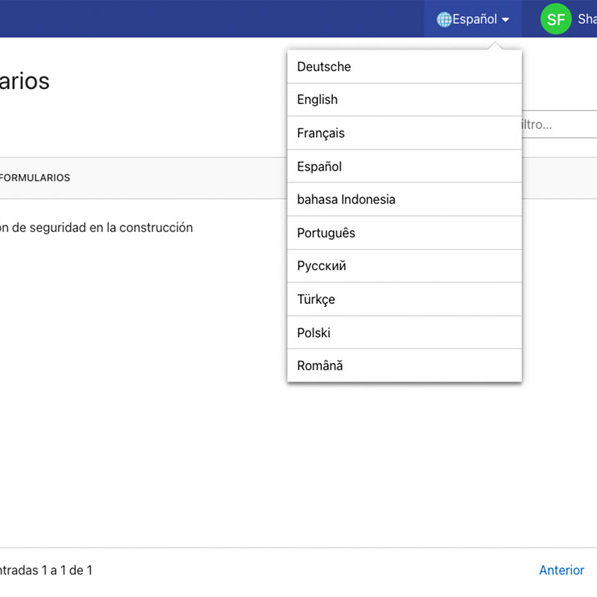

11

Languages

"The Weever suite is easy to understand and the support from the team has been amazing!"

Laura Curtis - Operational System and Process Manager, HelloFresh

"Weever saves me time, makes data visible and drives results!"

DENAIR M. - Training Manager

"Weever has changed how I run our business."

Ingrid K. - Plant Director

"Weever is extremely easy to use and simple to manage."

NICKI V - CI Engineer

"Weever gives me immediate insights into my business."

COLIN H. - Operational Excellence Manager

"The Weever team are extremely helpful and are always on hand to help with any questions or queries we may have."

Mel Cadle - Op Ex Lead Process Engineer, HelloFresh